Concentric double-pipe under-pressure operation water injection packer

A technology with pressurized operation and concentric double pipes, which is applied in the direction of sealing/isolation, production fluid, wellbore/well components, etc., can solve the problems of high setting pressure, damaged inner tubing, easy to lose seal, etc., and achieve the goal of setting Low pressure, avoid resistance, ensure long-term effective sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

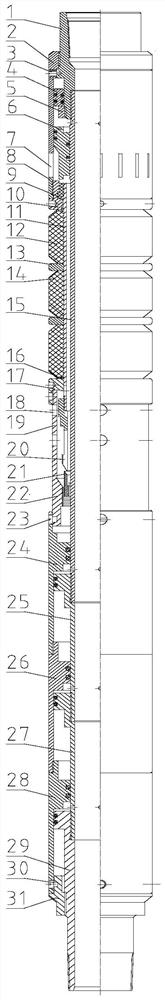

[0025] see figure 1 , a concentric double-tube water injection packer under pressure, including an upper joint 1, a retaining ring 2, an unsealing pin 3, a balance piston 4, a retaining ring 5, a backwash valve 6, a backwash inlet 7, and an upper cylinder liner 8 , L-shaped gasket 9, gland 10, rubber tube outer tube 11, end rubber tube 12, spacer ring 13, middle rubber tube 14, inner tube 15, split wrist guard 16, adjustment ring 17, backwash outlet 18 , lock sleeve 19, split lock claw 20, cone ring 21, inverted tooth buckle 22, setting pin 23, upper piston 24, upper central tube 25, middle piston 26, lower central tube 27, lower piston 28, lower joint 29 , anti-blocking pin 30, pin seat 31.

[0026] The L-shaped sealing gasket 9 is put into the gland 10, and the gland 10 is connected with the upper end of the outer tube 11 of the rubber tube by a screw, and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com