A hydraulic setting tool

A technology of hydraulic setting and tools, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc. It can solve the problems of inconvenient construction, difficult seating of balls, and inability of hydraulic setting tools to adapt to a large number of on-site constructions, etc., and achieves compact structure, short size, Low setting pressure and strong passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

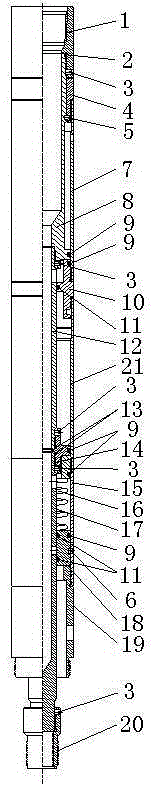

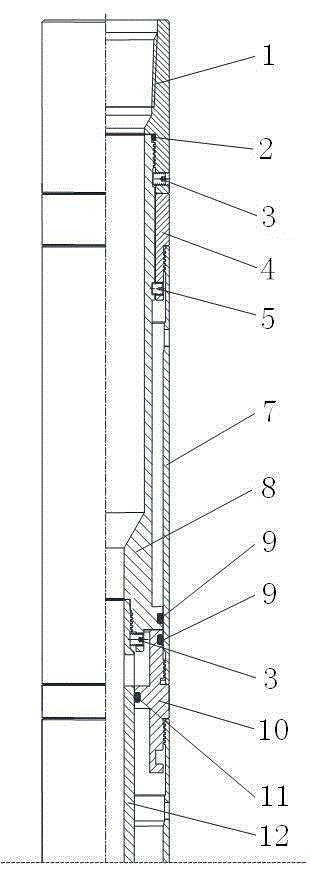

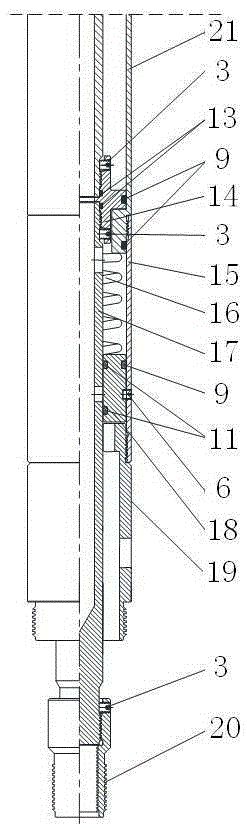

[0023] This embodiment provides a hydraulic setting tool, which mainly includes an upper joint 1, an O-ring 2, a set screw 3, a shear sleeve 4, a shear pin 5, a shear pin 6, an upper cylinder liner 7, and a mandrel 8 , O-ring 9, upper piston 10, O-ring 11, upper central tube 12, O-ring 13, intermediate joint 14, connecting cylinder liner 15, spring 16, lower central tube 17, lower piston 18, connecting sleeve 19, Lower joint 20, lower cylinder liner 21.

[0024] The lower end of the mandrel 8 is loaded into the O-ring 9, and the shear sleeve 4 is inserted into the upper end of the mandrel 8 and the shear pin 5 is installed. After the lower end of the upper joint 1 is loaded into the O-ring 2, it is connected with the mandrel 8 by threads, and is fixed with a set screw 3 to prevent loosening. The upper central tube 12 is connected with the mandrel 8 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com