Single-motor head and tail end cropping device of automatic edge banding machine

A technology of edge banding machine and single motor, which is applied to sawing equipment, wood processing equipment, circular saws, etc., and can solve the problem of increased cost of small edge banding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

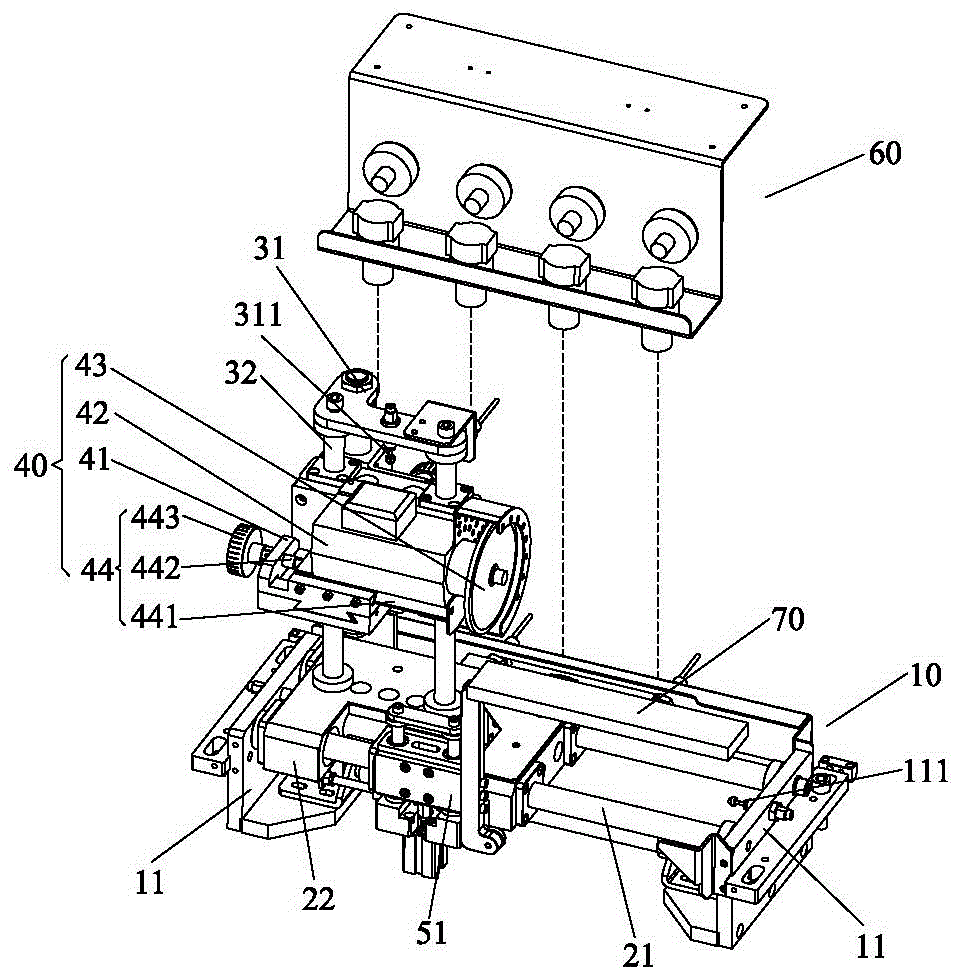

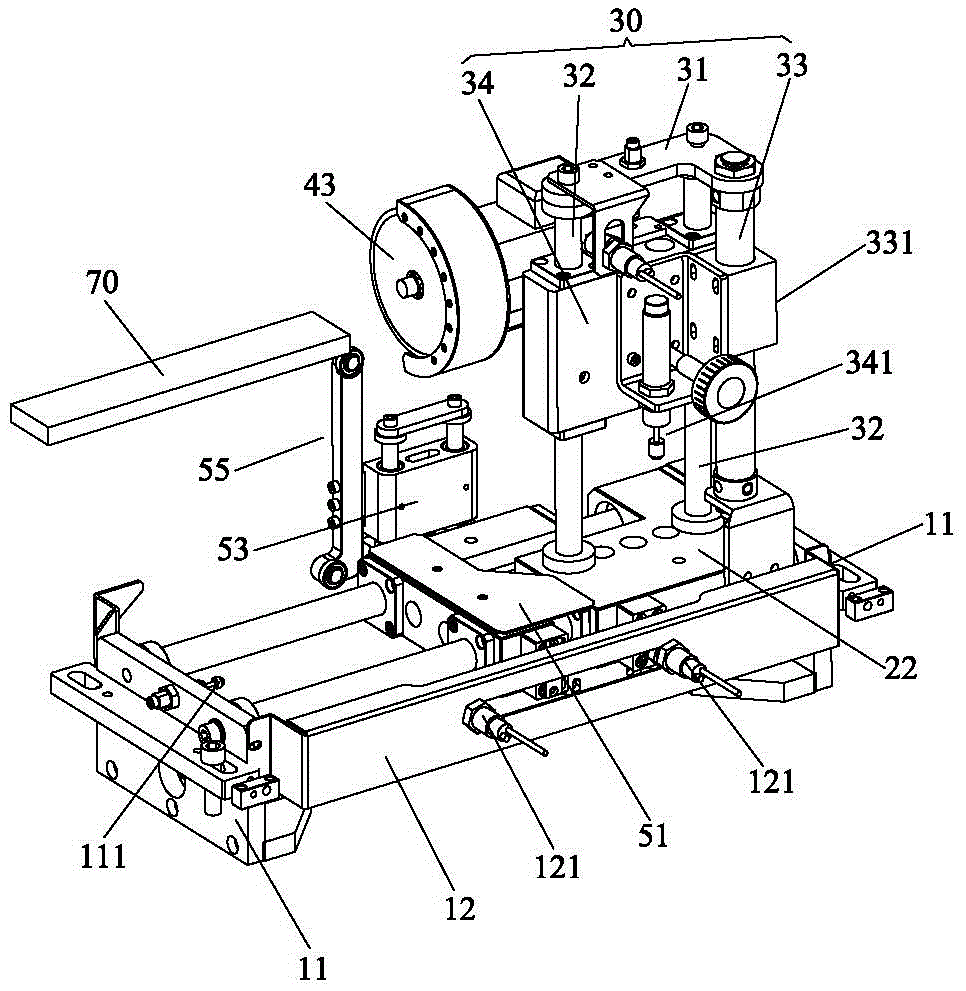

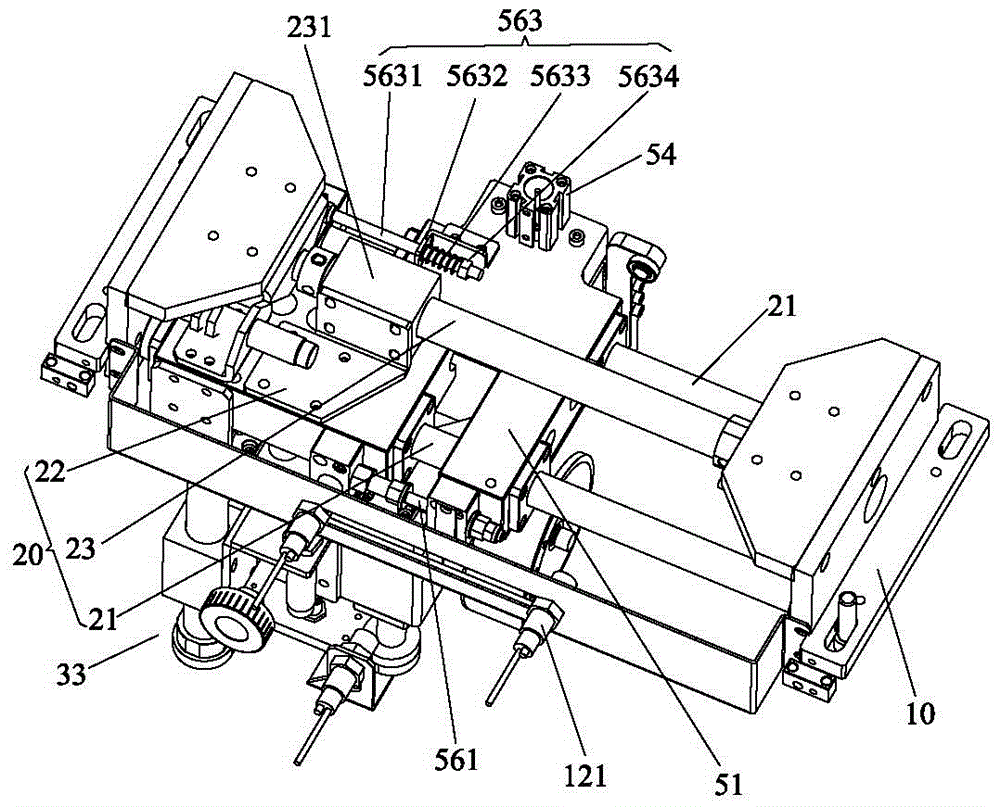

[0044] The present invention as Figure 1 to Figure 5 As shown, a single-motor head and tail cutting device for an automatic edge banding machine includes a frame 10, a horizontal sliding assembly 20 installed on the frame 10, a vertical sliding assembly 30, a head and tail cutting assembly 40, and a head and tail cutting assembly. The tracking assembly 50 and the pressure regulating valve part 60 for adjusting the pneumatic pressure of each assembly, wherein:

[0045] The frame 10 includes two supporting boards 11 and a cross bar 12 connected to the two supporting boards 11 .

[0046] The horizontal slide assembly 20 includes a horizontal guide rod 21 horizontally connected between the two support plates 11 of the frame 10, a horizontal slide seat 22 slidably installed on the horizontal guide rod 21, and a horizontal slide seat 22 for driving the horizontal slide seat. 22. A horizontal rodless cylinder 23 that slides on the horizontal guide rod 21. The horizontal rodless cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com