Linkage setting and flow dividing leakage finding tool

A technology of linkage and tools, applied in the direction of production fluid, sealing/isolation, wellbore/well components, etc., can solve problems such as fuzzy judgment of leakage points, failure of restrictors, poor pressure stabilization effect, etc., to eliminate mutual interference, Realize the effect of low force setting and ensure the effect of stabilizing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

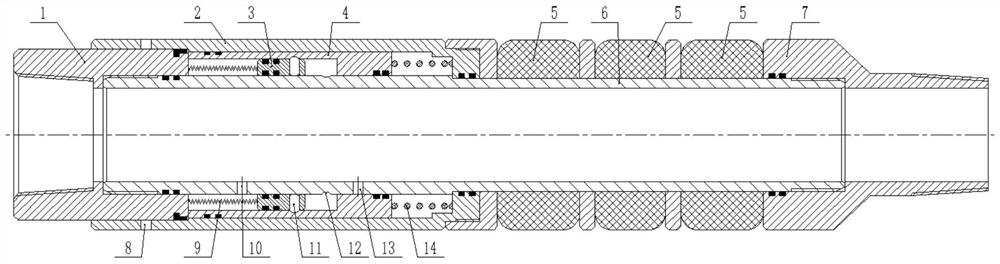

[0027] like figure 1 As shown, this embodiment includes an upper joint 1, a central pipe 6, a setting piston 2, a rubber cylinder 5 and a lower joint 7, and the upper joint 1 and the lower joint 7 are respectively threaded to the upper and lower ends of the central pipe 6, and the setting Both the piston 2 and the rubber tube 5 are set on the outside of the central tube 6, and the central tube 6 is provided with a liquid hole. When setting, pressurize into the central tube 6, and the pressure is transmitted to the setting piston 2 after passing through the liquid hole. Pushed by the pressure, the setting piston 2 slides along the outer wall of the central tube 6, and then compresses the rubber tube 5 to make the rubber tube 5 set. The above are common structures in the prior art, and will not be repeated here.

[0028] like figure 1 Shown, the innovation of the present invention is:

[0029] In the present invention, an ingenious spring mechanism is arranged in the setting ...

Embodiment 2

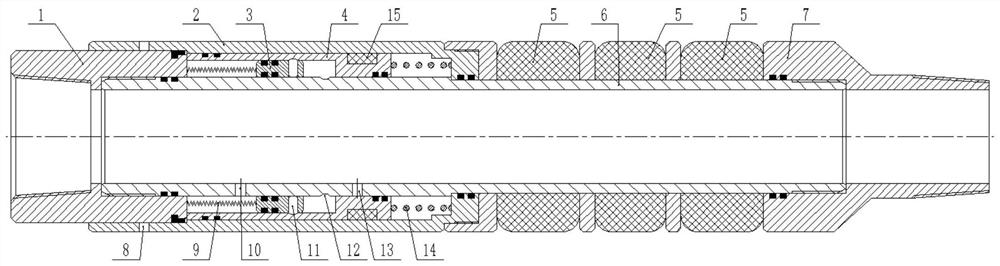

[0039] like figure 1 As shown, the difference between the present embodiment and the first embodiment is that a damping ring 15 for increasing the friction between the setting piston 2 and the outer sliding sleeve 4 is installed on the outer side of the outer sliding sleeve 4 . When unsealing, the setting piston 2 can slide upwards simultaneously with the inner sliding sleeve 3 under the drive of the outer sliding sleeve 4, which calmly and thoroughly eliminates the hindrance of the friction force everywhere on the reset of the rubber cartridge 5, and ensures that the rubber cartridge 5 is completely reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com