An oil-casing threaded connection air tightness detection packer

A technology of air tightness detection and threaded connection, which is used in casing, liquid/vacuum degree for liquid tightness measurement, drilling pipe, etc. It can avoid problems such as uneven setting of the device, so as to achieve the effect of stable setting process, avoiding waste, and facilitating maintenance and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

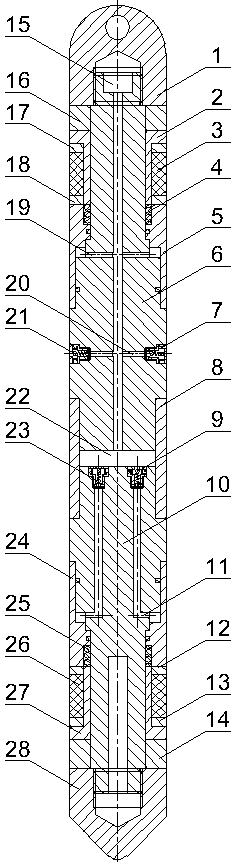

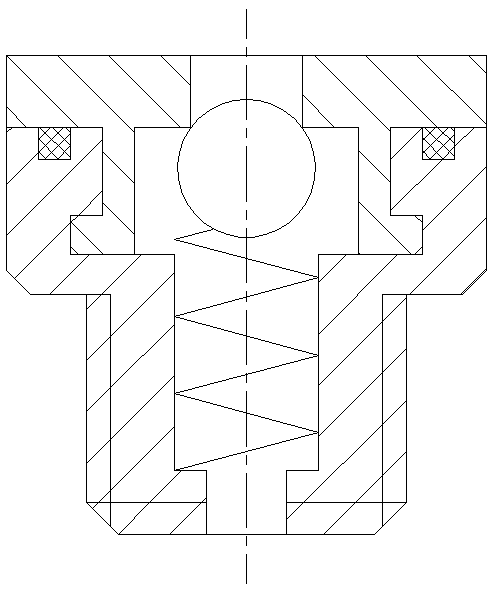

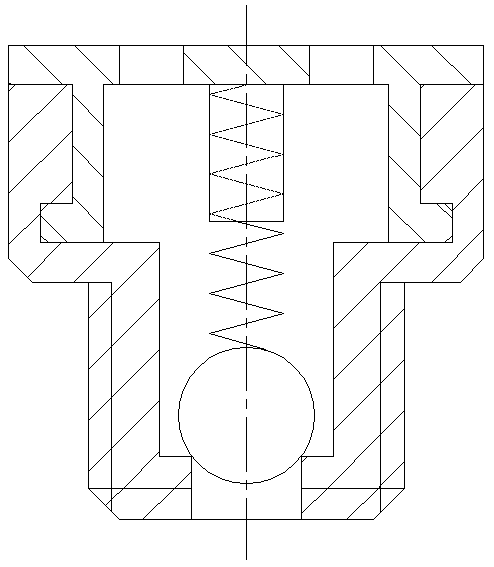

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the oil-casing thread is connected to the air-tightness detection packer, including the connecting sleeve 8, the upper central pipe 6 and the lower central pipe 10, and the feature is that the connecting sleeve 8 connects the upper central pipe 6 and the lower central pipe 10 connections;

[0027] The upper central tube 6 includes a lower thick tube and an upper thin tube; the thick tube is provided with an intermediate transverse channel 20, and the first one-way air intake valve 7 and the first one-way air inlet valve 7 and the first one-way inlet valve are respectively installed at the two ends of the channel. Air return valve 21 two one-way valves; there is a step transition between the thick tube and the thin tube, the position of the step is provided with an upper transverse passage 19, the upper central tube 6 is covered with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com