A guiding mechanism suitable for four-suspension module maglev vehicles

A technology of guiding mechanism and guiding structure, which is applied to vehicle components, electric vehicles, electric traction, etc., can solve the problems of large load of guiding mechanism, affecting the suspension frame, unfavorable vehicles entering and exiting small radius curves, etc., so as to increase flexibility and reduce comprehensive The effect of lateral stiffness and lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

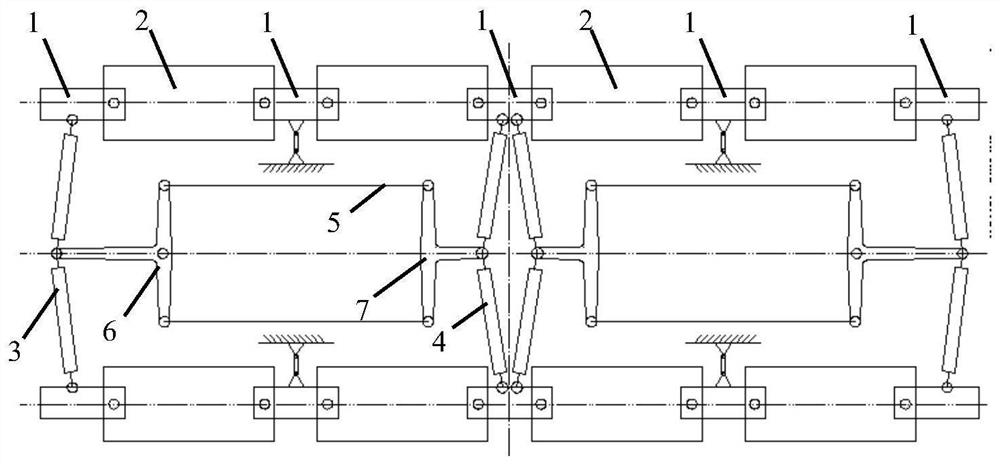

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

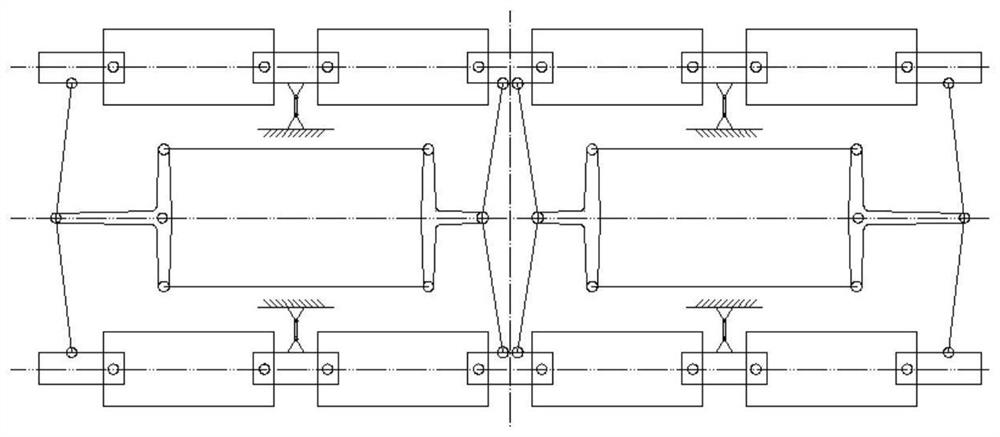

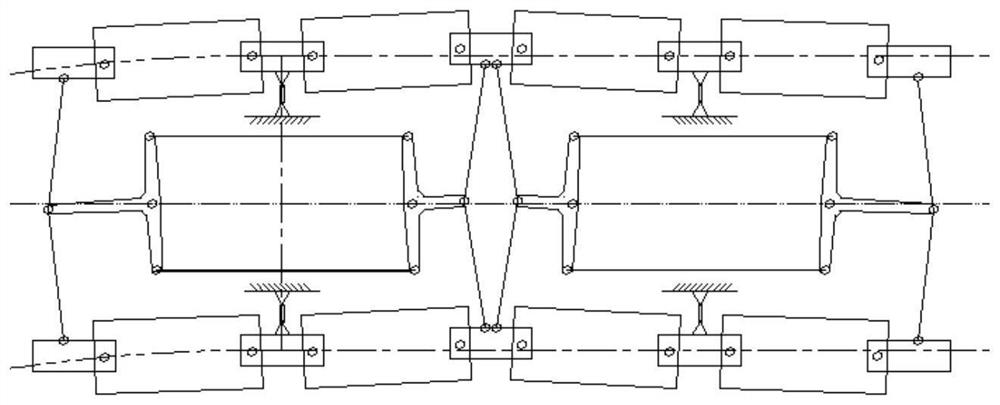

[0029] see Figure 3-6 , the guiding mechanism for the four-suspension module, which includes the first to fifth pairs of sliding tables 1 arranged in the longitudinal direction, which are respectively one, two, ... five-position sliding tables, and each pair of sliding tables is arranged in the transverse direction , the first, third, and fifth pairs of slides 1 are movable slides, and the movable slides are located under the car body (not shown), and the bottom of the car body has guide rails for guiding the movable slides, and the movable slides can be moved along Move laterally along the guide rail. The second and fourth pairs of slides are fixed slides. The fixed slides are fixed at the bottom of the car body. The two slides are connected, and the five slides arranged in the longitudinal direction correspond to four suspension modules (the suspension mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com