A V-shaped ball valve and its flow characteristic curve obtaining method

A technology of flow characteristics and ball valves, which is applied to valve devices, cocks including cut-off devices, mechanical equipment, etc., can solve problems such as poor adjustment performance, achieve large adjustable ratio, excellent adjustment performance, and save manpower and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

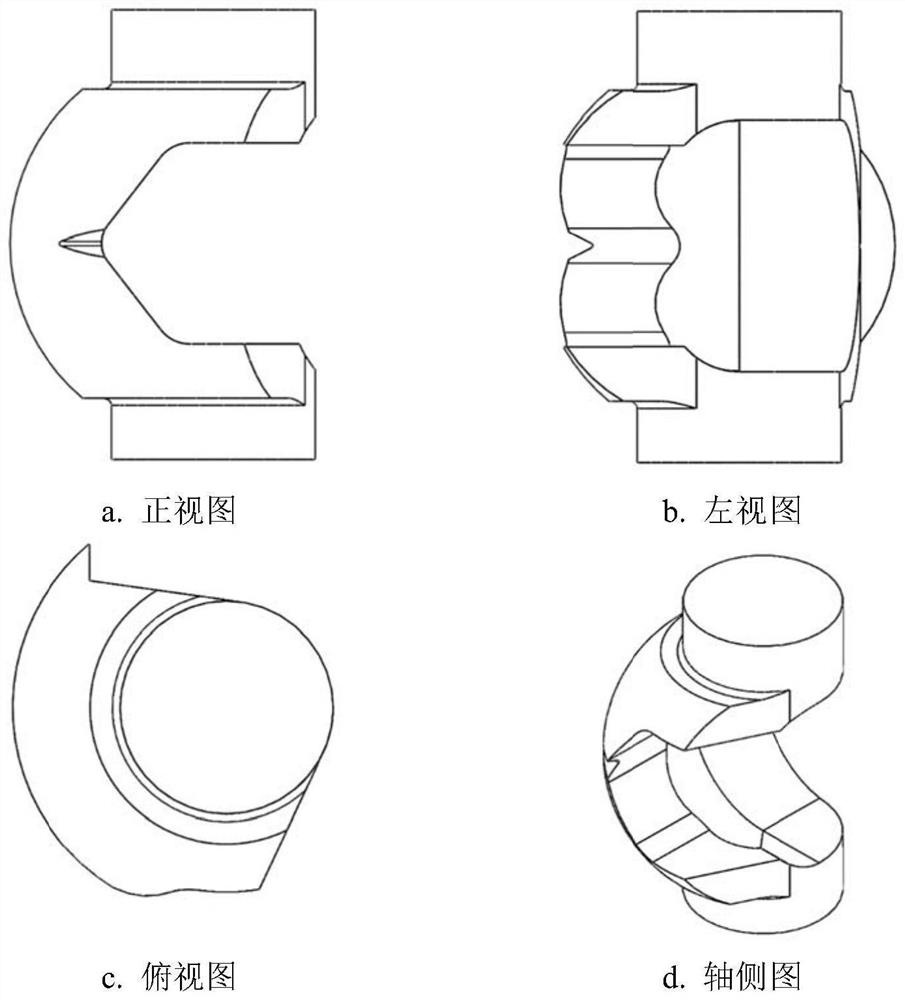

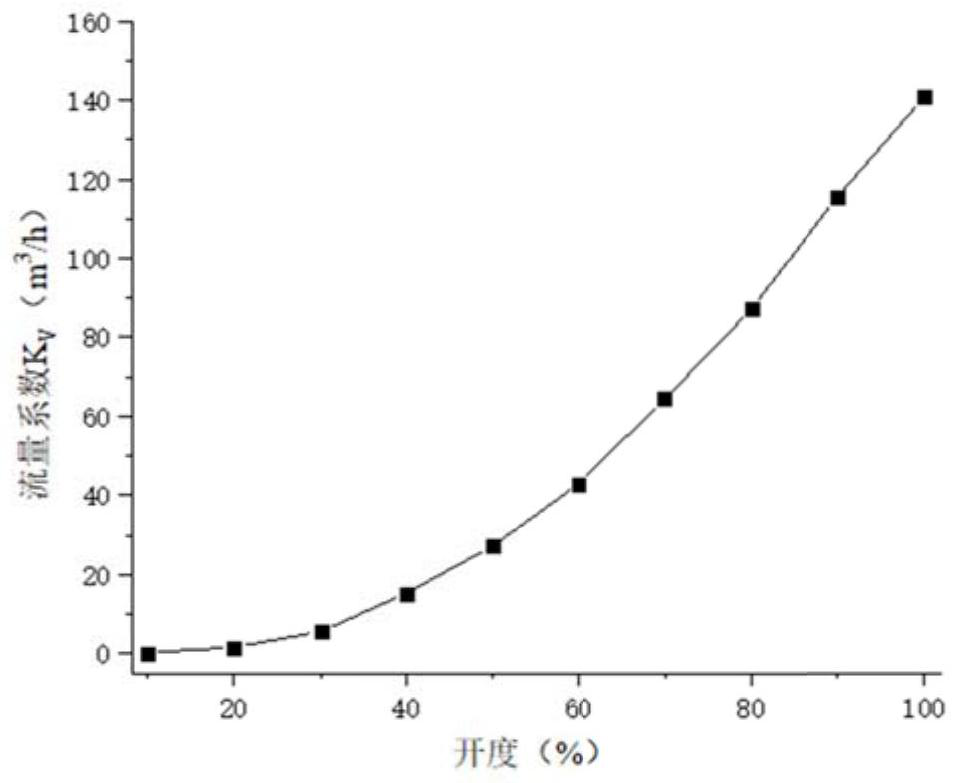

[0072] The invention relates to a V-shaped ball valve. The V-shaped ball valve has good adjustment performance under large opening and small opening, and has a high adjustable ratio. The traditional V-type ball valve is an angle-turn regulating valve, and the tower is formed by opening a V-shaped opening on the ball. During the rotation of the ball, the V-shaped opening of the ball and the flow channel of the valve seat form a fan-shaped effective flow channel. During the rotation process, the cross-sectional area of the effective flow channel can be changed to form a precise adjustment of the medium.

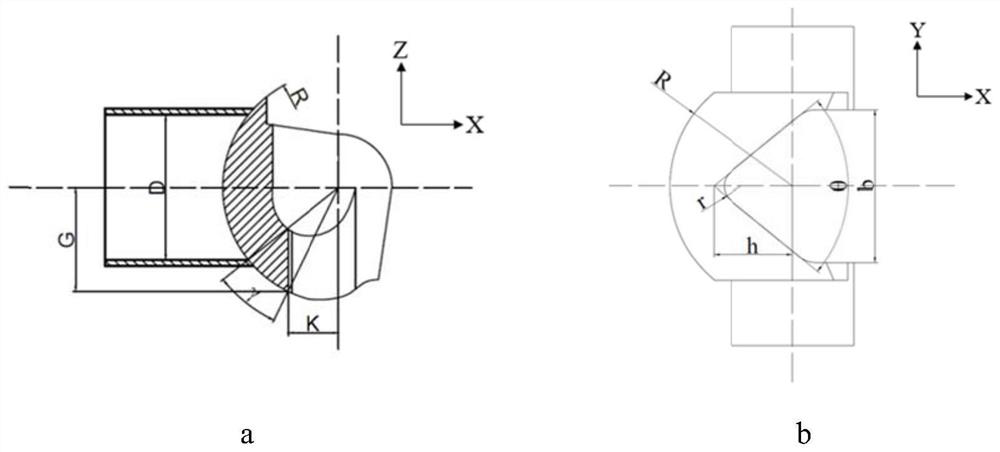

[0073] Such as figure 1 As shown, in the V-type ball valve provided by the present invention, the spool opening of the V-type ball valve consists of three continuous sections. Among them, the first section of the valve core flow channel is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com