A four-pipe heating unit recovery system and its control method

A technology of a recovery system and a control method, which is applied to the recovery system of a four-pipe heat unit and its control field, can solve the problems that cannot be realized, cannot accurately reflect the real-time demand of the unit, and infinitely adjust the temperature of the heat recovery outlet water, so as to solve the problem of speed lag. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

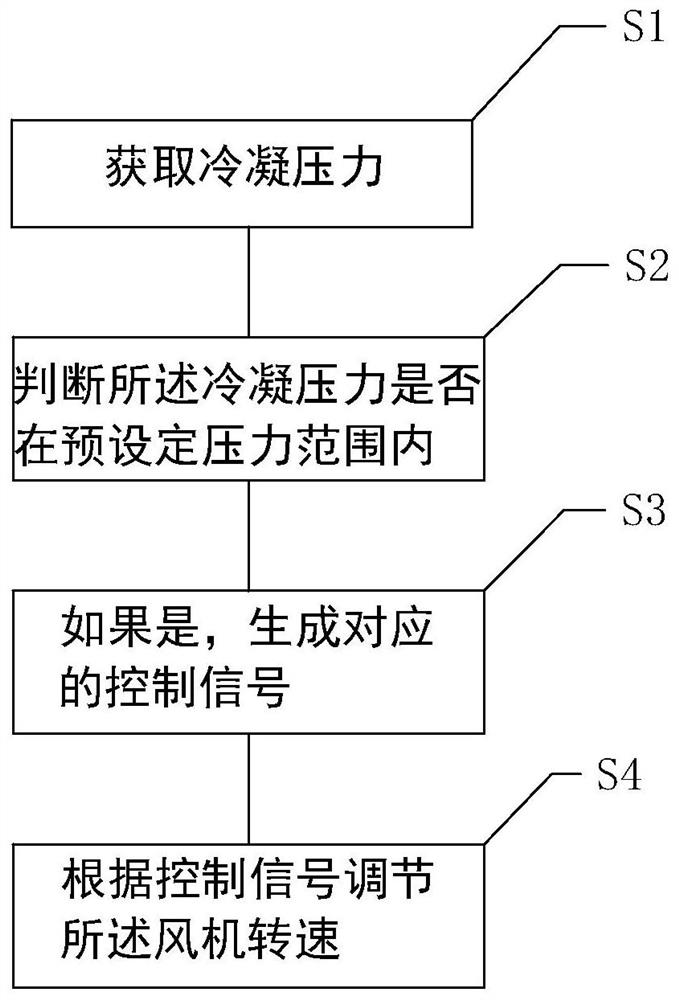

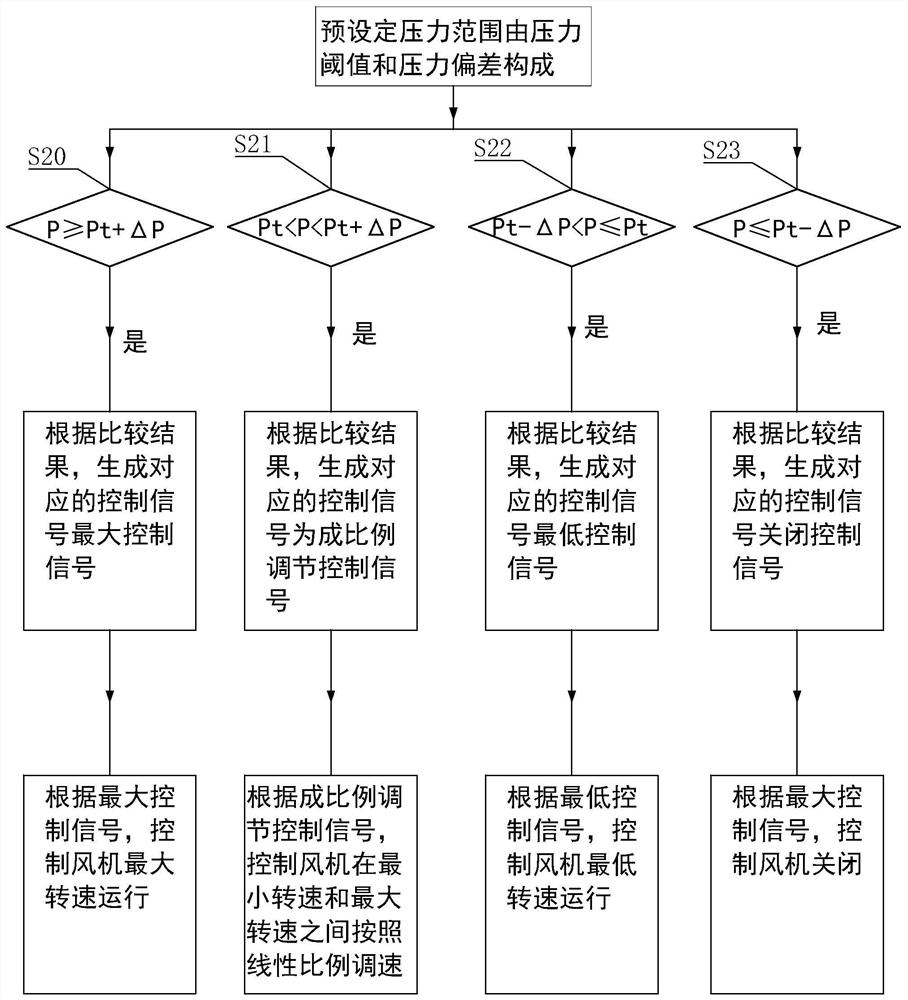

[0045] Such as figure 1 and figure 2 As shown, a control method of a four-pipe heating unit recovery system is based on a four-pipe heating unit recovery system. The system includes a fan and a plate heat exchanger, and a pressure sensor for detecting the condensation pressure is provided on the condensation outlet side of the plate heat exchanger;

[0046] The control method comprises the following steps:

[0047] Step S1, obtaining the condensation pressure;

[0048] Step S2, judging whether the condensing pressure is within a preset pressure range;

[0049] Step S3, if yes, generating a corresponding control signal;

[0050] Step S4, adjusting the fan speed according to the control signal.

[0051] By adopting the method of the present invention, the operating state of the unit is monitored in real time, and the speed of the fan is adjusted steplessly within a certain range, thereby realizing the purpose of heat recovery and outlet water temperature; the problem of lag...

Embodiment 2

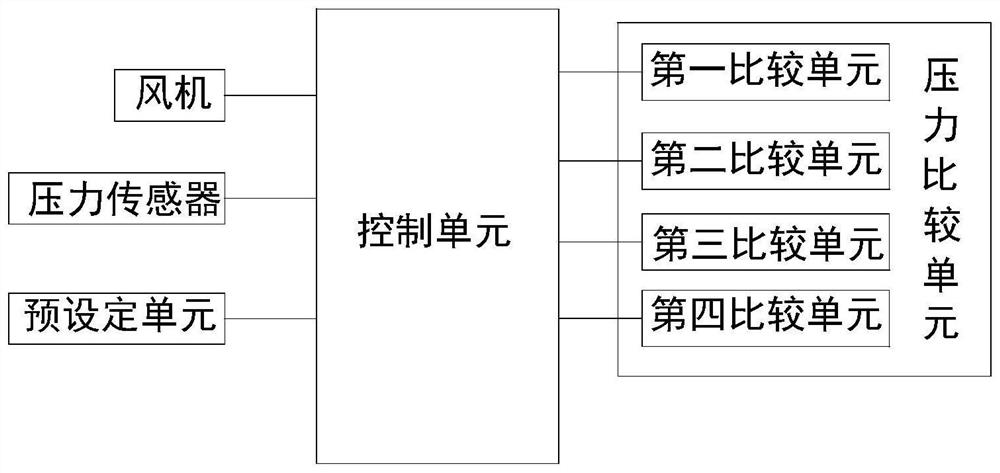

[0071] Such as image 3 As shown, a four-pipe heating unit recovery system includes a fan, a plate heat exchanger, a pressure sensor installed on the condensation outlet side of the plate heat exchanger to detect the condensation pressure, and a control unit electrically connected to the fan and the pressure sensor respectively ; Also includes a pressure comparison unit, the pressure comparison unit is used to judge whether the condensing pressure is within the preset pressure range; if so, generate a corresponding control signal, which is transmitted to the control unit; the control unit adjusts the fan steplessly according to the control signal Rotating speed. The control unit includes a fan speed controller, a frequency converter or a variable frequency drive, wherein the fan speed controller is used to detect the pressure signal, and output a DC voltage signal corresponding to 0-10V according to the pressure signal, wherein the frequency converter or variable frequency dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com