Heavy-duty gas turbine generator rotor coil structure suitable for variable-frequency starting

A gas turbine generator and rotor coil technology, which is applied to the shape/style/structure of winding insulation, the shape/style/structure of winding conductors, electric components, etc. Problems with unbalanced loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

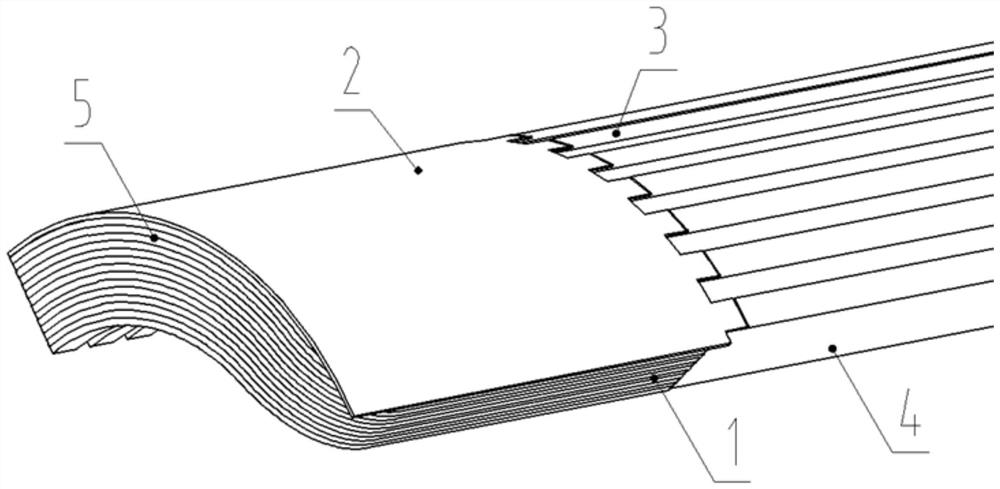

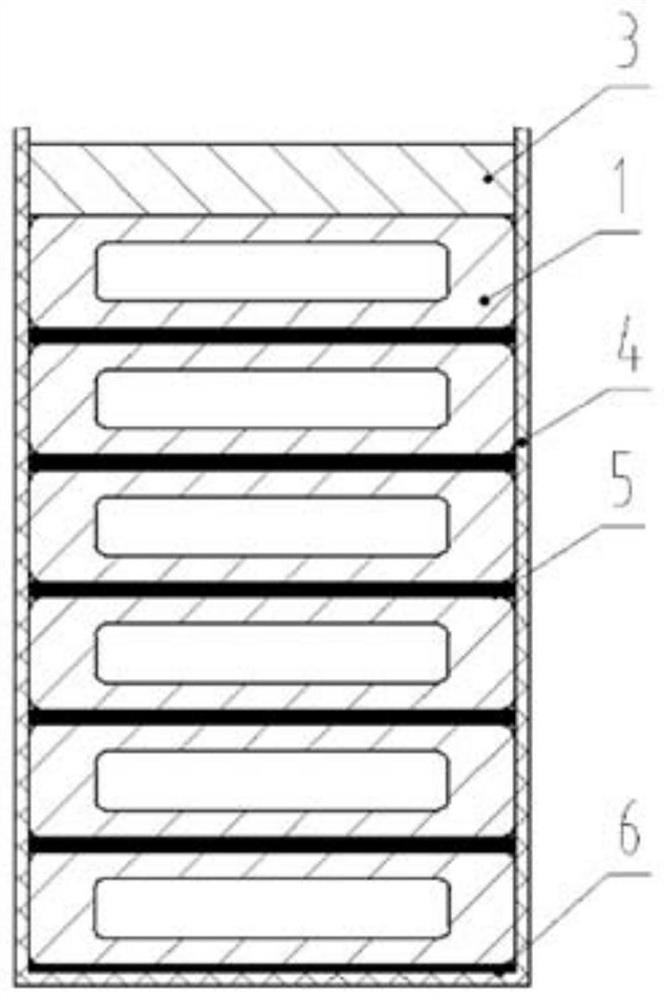

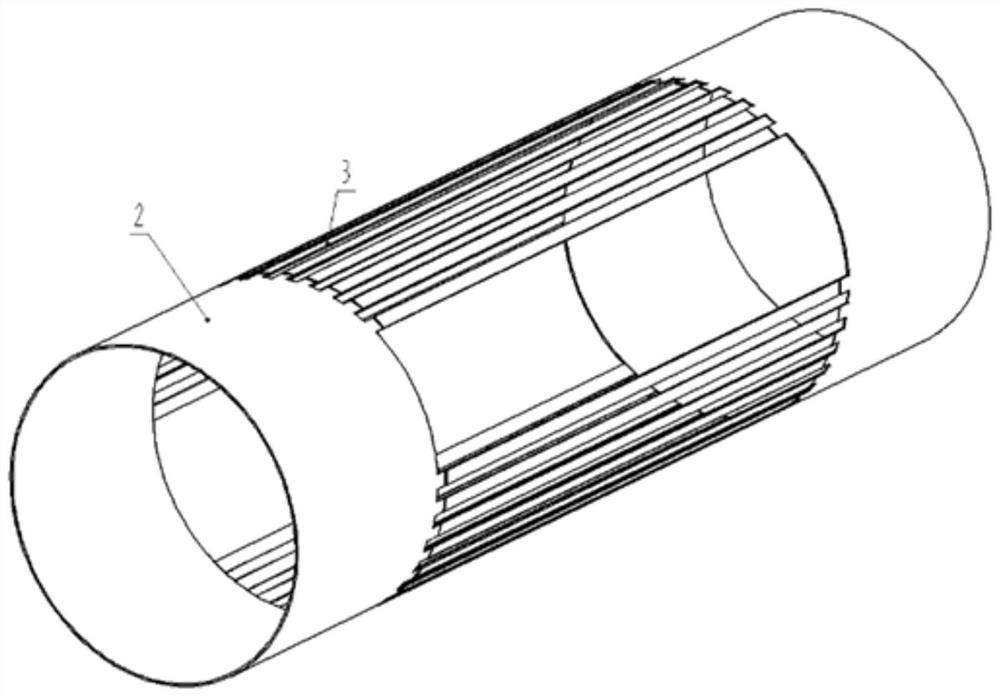

[0018] refer to Figure 1-3 As shown, a heavy-duty gas turbine generator rotor coil structure suitable for variable-frequency start-up includes hollow-type excitation winding 1, squirrel-cage damping winding, slot insulation 4, turn-to-turn insulation 5 and slip layer 6; the hollow-type The field winding 1 is provided with several layers of inter-turns, and inter-turn insulation 5 is provided between two adjacent layers of turns; the squirrel-cage damping winding is arranged outside the hollow field field winding 1; the hollow field field The winding 1 and the rotor embedding slot are sealed by the slot insulation 4; a slip layer 6 is provided between the lowermost coil of the hollow excitation winding 1 and the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com