Anticorrosion coating device suitable for multi-variable-diameter stainless steel straight pipe

A coating device, stainless steel technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of multi-diameter pipe anticorrosion, diameter is not a fixed value, and it is difficult to apply multi-diameter pipes, etc., to achieve The effect of improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

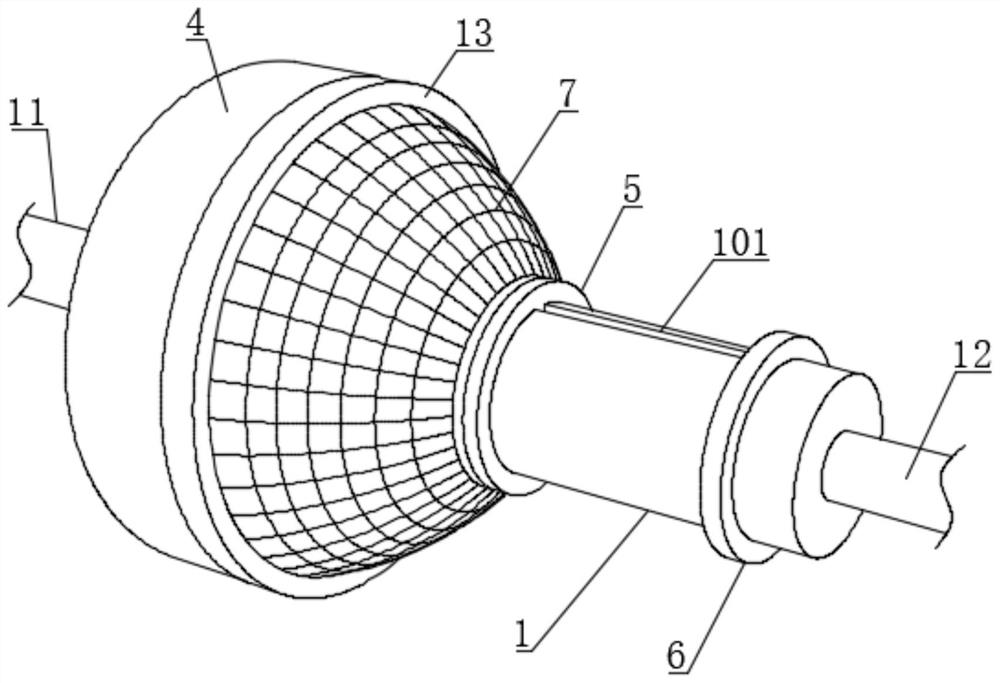

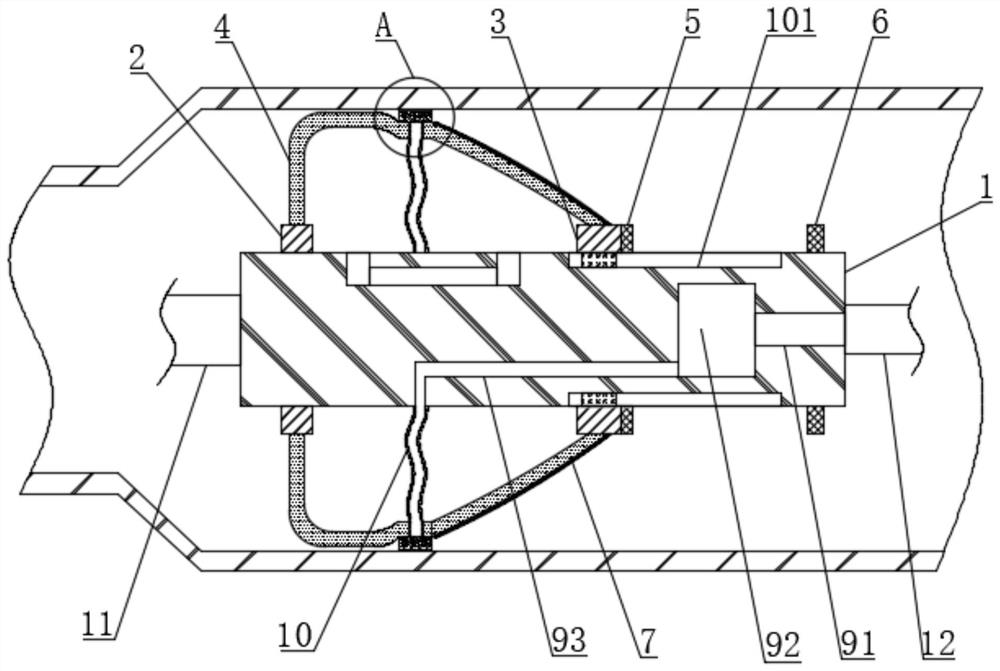

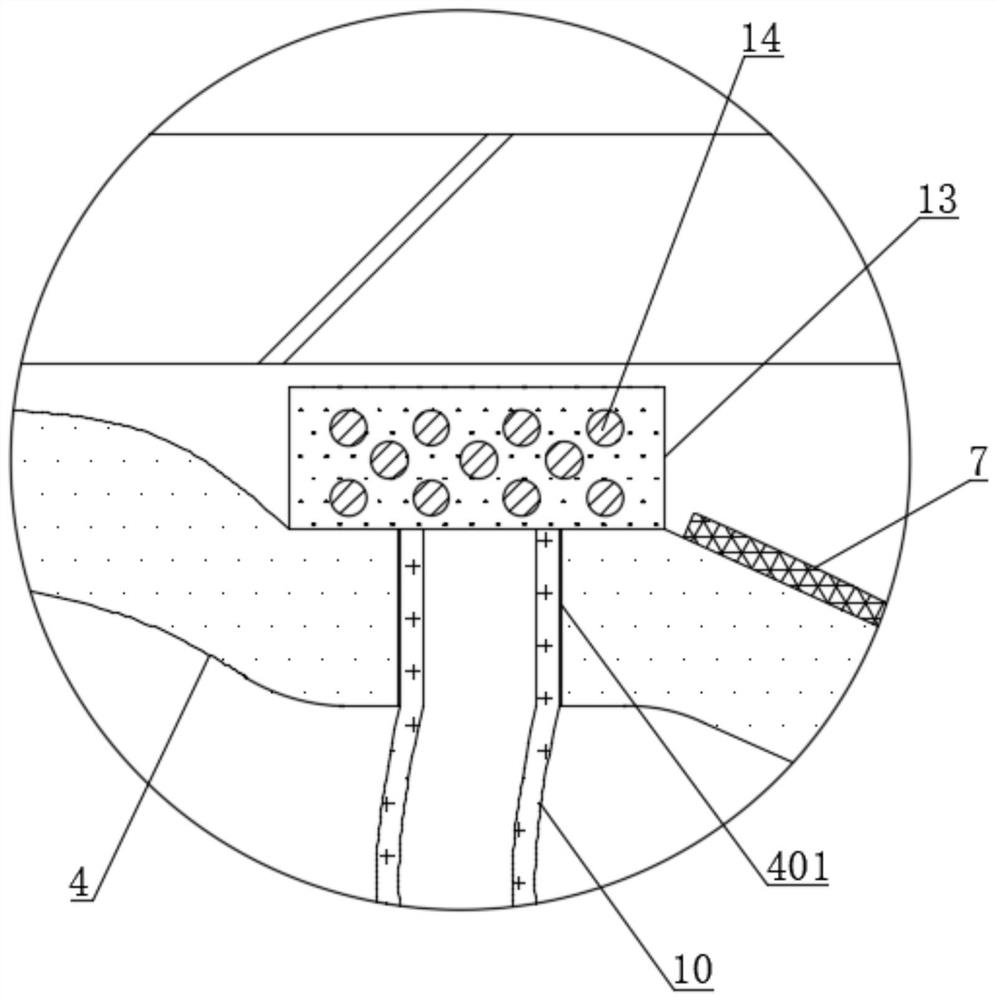

[0041] see figure 1 and figure 2 , an anti-corrosion coating device suitable for stainless steel straight pipes with multiple variable diameters, comprising an inner rod 1, the left end of the inner rod 1 is fixedly connected with a draw rod 11, and the end of the draw rod 11 far away from the inner rod 1 is connected with a pulling device, and the inner rod 1 is provided with a fixed ring 2, a moving ring 3 and an elastic capsule 4, the fixed ring 2 is located between the moving ring 3 and the drawbar 11, the fixed ring 2 is fixedly connected to the outer end of the inner rod 1, and the moving ring 3 is connected to the inner rod 1. The outer end of the rod 1 is slidingly connected, the left and right ends of the elastic capsule 4 are fixedly connected with the outer ends of the fixed ring 2 and the moving ring 3 respectively, and the outer end of the inner rod 1 is also fixedly connected with a secondary magnetic ring 6, and the secondary magnetic ring 6 Located on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com