Rock wool storage conveying device

A conveying device and rock wool technology, applied in the field of conveyors, can solve the problems of unstable overall structure of the conveying trolley, inconvenience to users, shaking of the conveying trolley, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

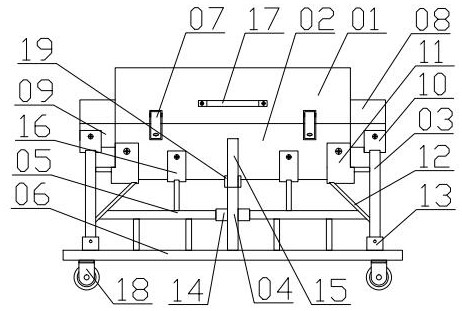

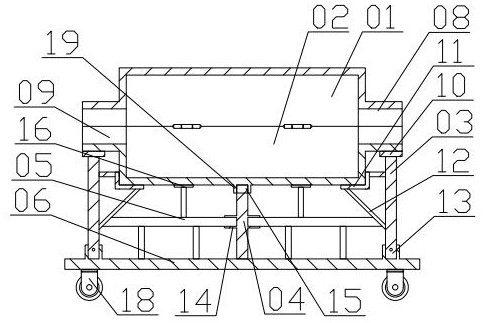

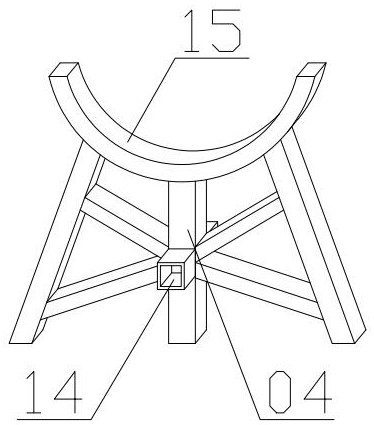

[0016] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0017] A rock wool warehousing transportation device, including No. 1 protective shell 01, No. 2 protective shell 02, No. 1 fixed support frame 03, No. 2 fixed support frame 04, No. 3 fixed support frame 05, trolley bottom plate 06, locking connection Plate 07, No. 1 auxiliary protective ear 08, the rear side of the No. 1 protective case 01 is connected to the No. 2 protective case 02 through a hinge, and the front side of the No. 1 protective case 01 is connected to the No. 2 protective case 02 through the locking connection plate 07. The upper part of the No. 1 protective shell 01 is connected to the handle 17. The left and right sides of the No. 1 protective shell 01 have No. 1 auxiliary protective ears 08. The No. 1 auxiliary protective ears 08 are symmetrically arranged, and the left and right sides of the No. 2 protective shell 02 have No. 2 auxiliary...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap