A multi-link connecting device with multi-angle adjustment and locking

A connecting device and multi-link technology, applied in the direction of connecting rod bearings, pivot connections, shafts and bearings, etc., can solve problems such as inconvenient installation, difficulty in installation and maintenance, and reduced bearing capacity of connecting rod structures, and achieve convenient installation, Easy disassembly, simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

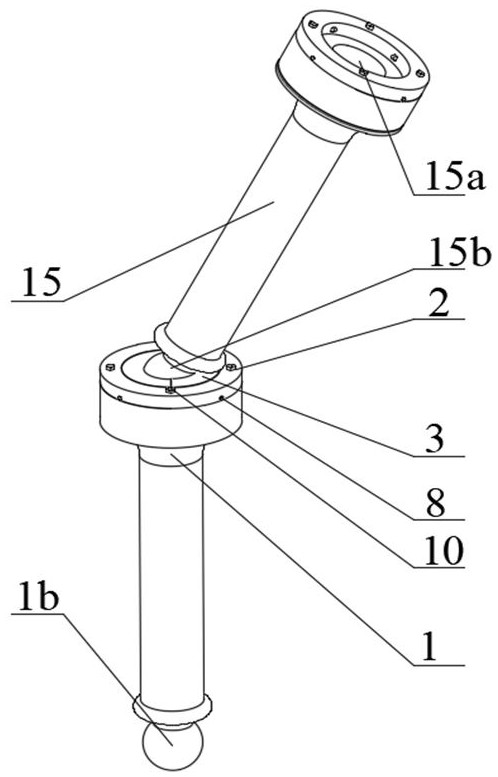

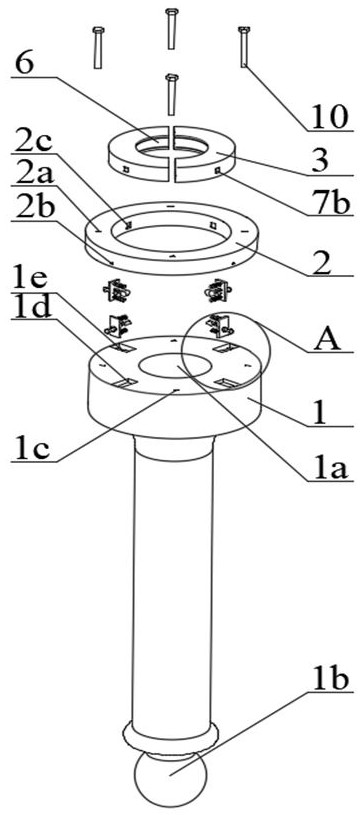

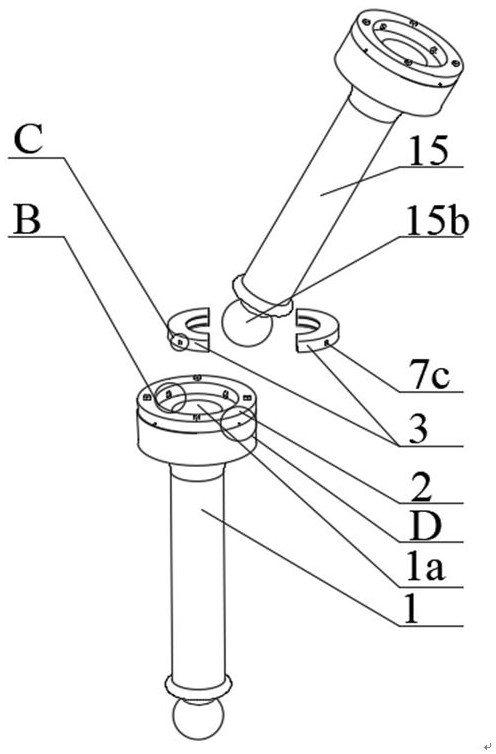

[0021] For ease of understanding, the spatial orientation of the present invention is now defined: see figure 1 , the second ball head 15b of the second connecting rod 15 is defined as "up", the position of the first ball head 1b of the first connecting rod 1 is "down", and the central axis direction of the first connecting rod 1 is defined as " Axial", the direction perpendicular to this is defined as "radial"; the axis of the central axis is defined as "inner", and the opposite direction is "outer".

[0022] see figure 1 , a multi-angle adjustment and locking multi-link connecting device of the present invention includes a plurality of connecting rods connected in series up and down, and the connecting parts of each two connecting rods are connected by a connecting rod cover 2 and a bearing 3, that is Connect the two connecting rods together with connecting rod cap 2 and bearing 3. figure 1 Taking only two links as an example, the connection structure and connection method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com