A double-sided powder coating and anti-adhesion jointing device for butterfly sides

A technology of butterfly noodles and connecting materials, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of butterfly noodles sticking to each other, increased labor costs, and increased labor costs of butterfly noodles, and achieves strong practicability, ingenious structure, Creatively conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

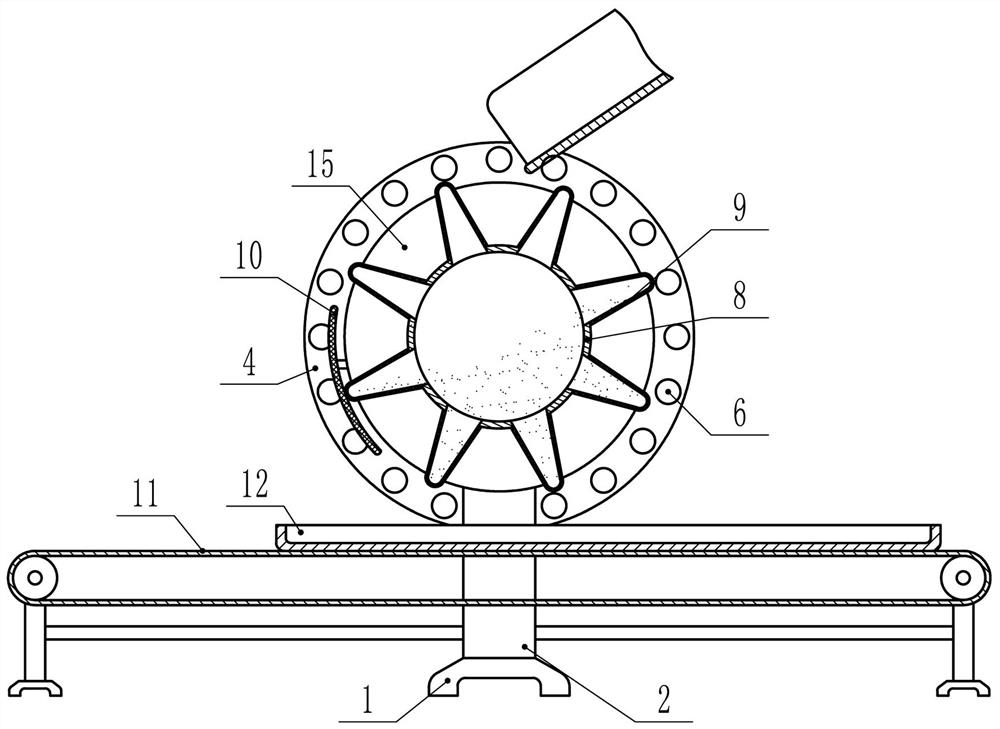

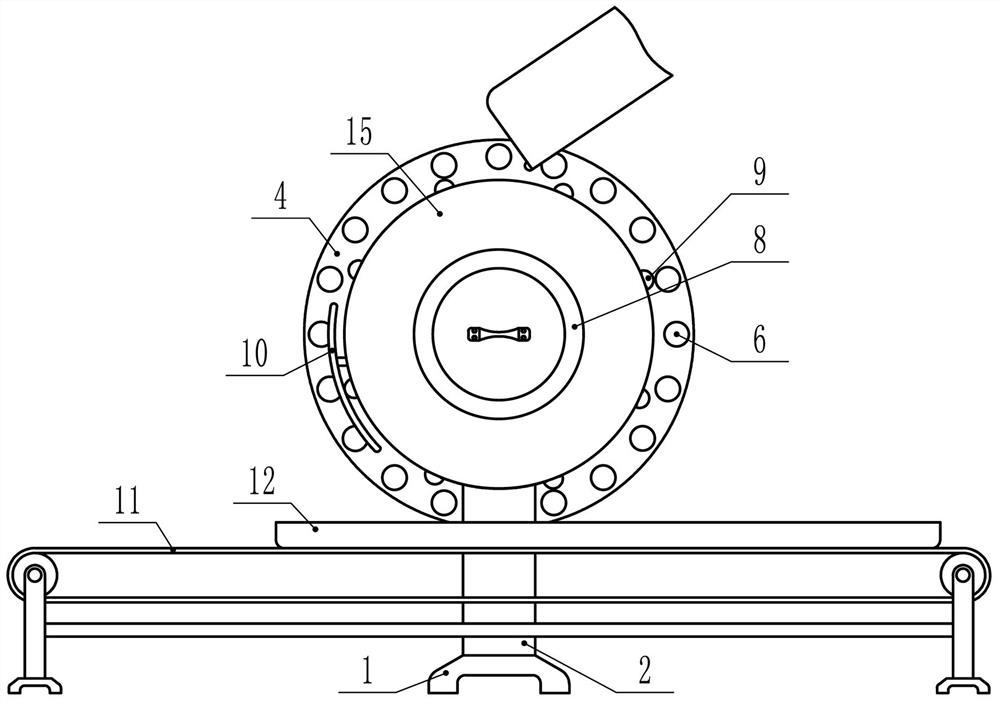

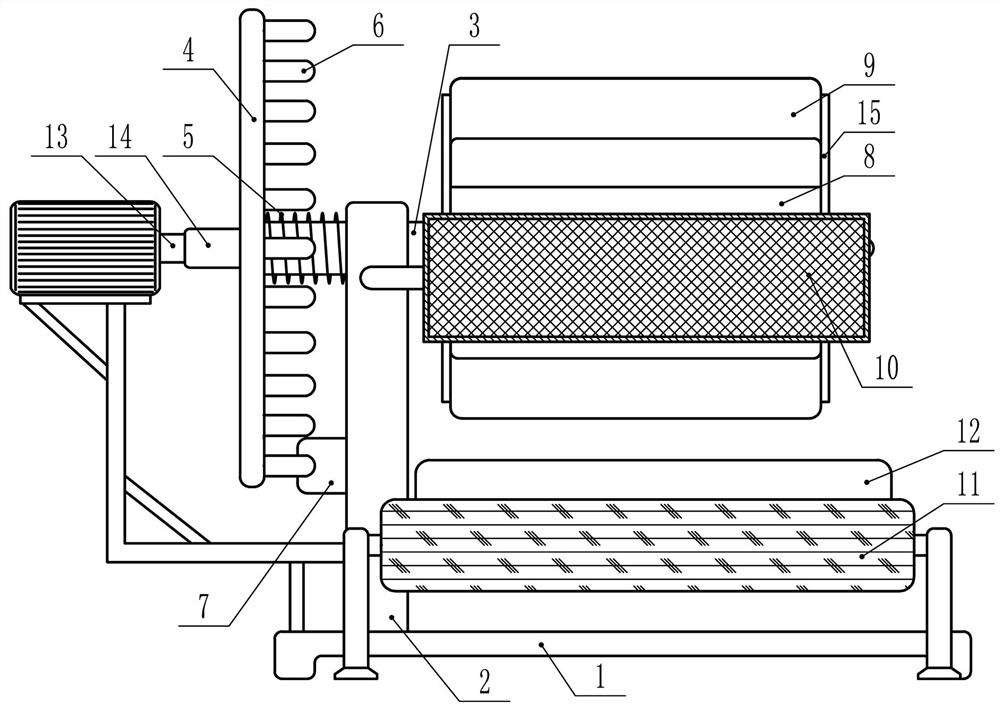

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Depend on Figure 1 to Figure 3 It can be seen that the present invention includes a base 1, a vertical board 2 is fixed on the rear side of the base 1, and the upper end of the vertical board 2 is penetrated and rotatably connected with a rotating shaft 3 that can move left and right. A turntable 4 is fixed, and the part of the rotating shaft 3 placed between the turntable 4 and the vertical plate 2 is covered with a tension spring 5. One end of the tension spring 5 is rotatably connected to the turntable 4, and the other end is fixed on the rear end surface of the vertical plate 2. The turntable The front end face circumference of 4 is evenly distributed with the ejector pin 6 of a plurality of vertical turntable 4 end faces, and the lower half of riser 2 rear side is provided with an arc protruding block 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com