Automatic conveying line lubricating system for fruit juice production

An automatic conveying and lubricating system technology, applied in the direction of transportation and packaging, non-rotational vibration suppression, rigid containers with short marks, etc., can solve the problems of system work efficiency reduction, fruit juice spilling out of the container, easy to shake, etc., to achieve effective It is beneficial to the automatic processing of the device, saves manual labor, and increases the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

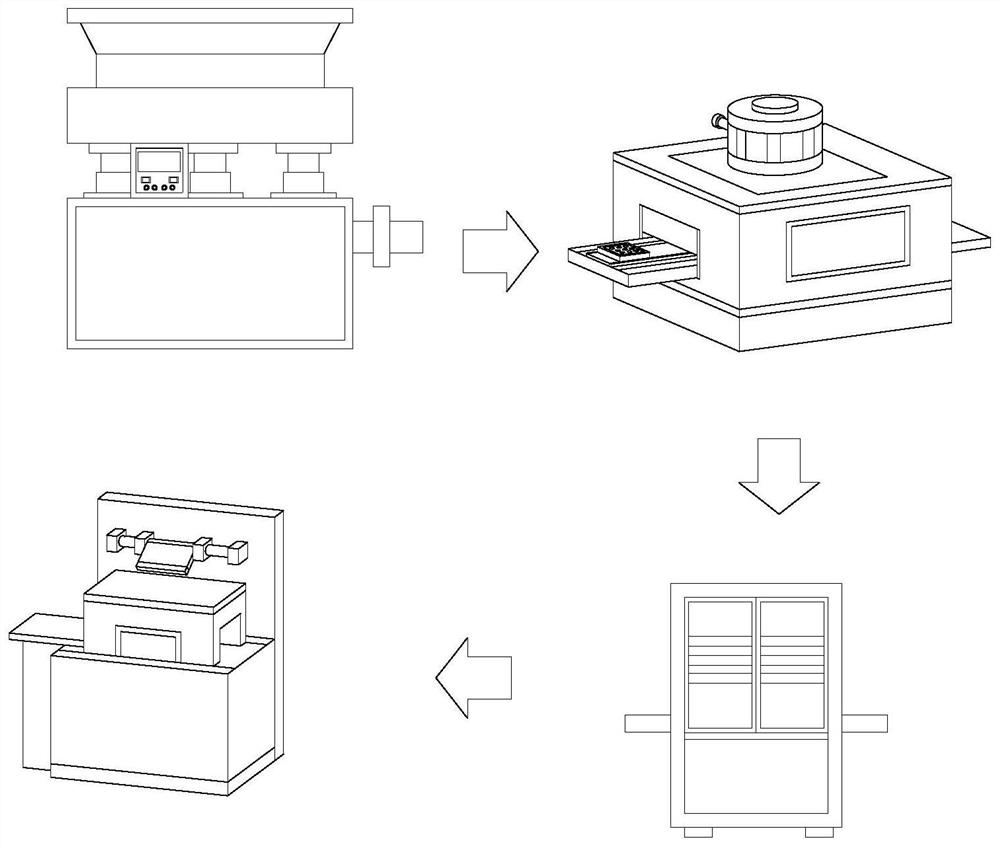

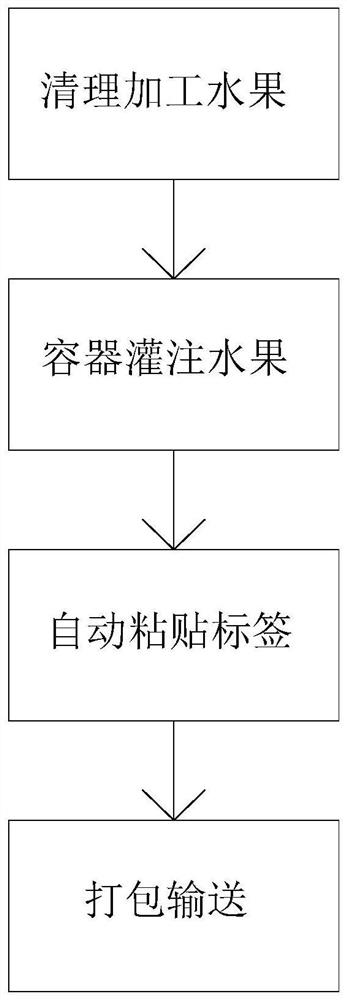

[0048] Such as Figure 1-8 As shown, the present invention provides an automatic conveying line lubrication system for fruit juice production, including fruit processing equipment, the side of the fruit processing equipment is fixedly connected with a transmission pipe, the other end of the transmission pipe is connected with a filling device, and the inside of the filling device A conveying platform is provided, and automatic labeling equipment is fixedly connected to one side of the conveying platform, and packaging equipment is fixedly installed on the side of the automatic labeling equipment away from the filling device. The automatic conveying line lubrication system for juice production also includes the following steps:

[0049] Step 1: Clean up the processed fruit;

[0050] Step 2: Fill the container with fruit;

[0051] Step 3: Paste the label automatically;

[0052] Step 4: Package and transport.

[0053] In this embodiment, the fruit is cleaned by the fruit proce...

Embodiment 2

[0055] Such as Figure 1-8 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, step 1 also includes the following steps: S1, placing the fruit in the fruit processing equipment for cleaning, and then the crushing mechanism at the bottom Carry out cutting and juicing, and then cooperate with the delivery pipe to transport the juice water to the inside of the filling device. S2. Transport the cutting and squeezing juice to the surface of the filter layer for simple filtration to filter larger particles, thereby improving the quality of the juice, and then The bottom of the fruit processing equipment is heated to 80-100 degrees for 25 minutes. Step 2 also includes: placing the container on the output belt and transferring it to the bottom of the infuser for filling, so as to achieve the function of automatic filling. Step 3 also includes: putting Output the filled glass bottle on the belt and move it to the inside of the automatic...

Embodiment 3

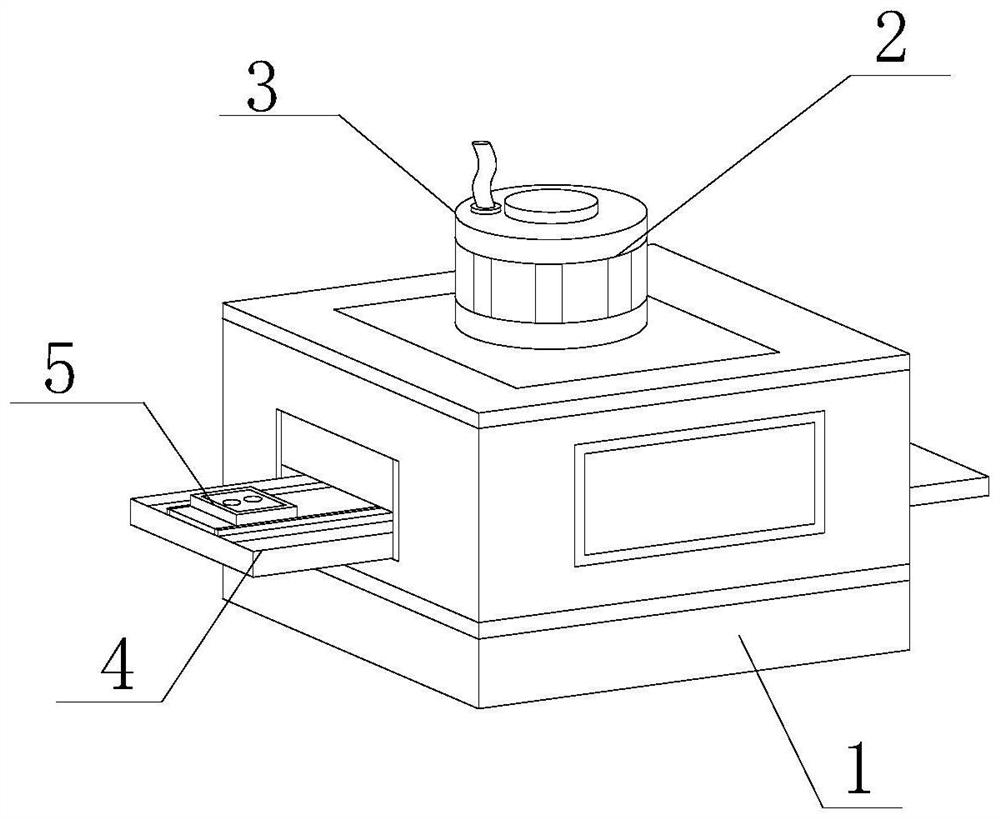

[0058] Such as Figure 1-8 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the perfusion device includes a processing box 1, the top of the processing box 1 is fixedly equipped with a guide tube 2, and the top of the guide tube 2 is provided with The conveying hose 3 is provided with a conveyor belt 4 inside the processing box 1, a glass container 5 is provided on the top of the conveyor belt 4, a rotating disk 35 is fixedly connected to the bottom of the conveying pipe 3, and a reinforcing block 34 is arranged on the top of the rotating disk 35. The top of reinforcement block 34 is fixedly installed with socket block 33, and the top of socket block 33 is provided with connecting rod 31, and the top of connecting rod 31 is fixedly installed with power motor 32, and the bottom of rotating disk 35 is provided with injection tube 36, One side of the bottom of the injection pipe 36 is provided with a limiting column 37, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com