A butterfly surface forming and receiving device

A material receiving device and butterfly noodle technology, which is applied in dough processing, baking, food science, etc., can solve the problems of butterfly noodle sticking to each other and increased labor costs, and achieve the effect of strong practicability, ingenious structure, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

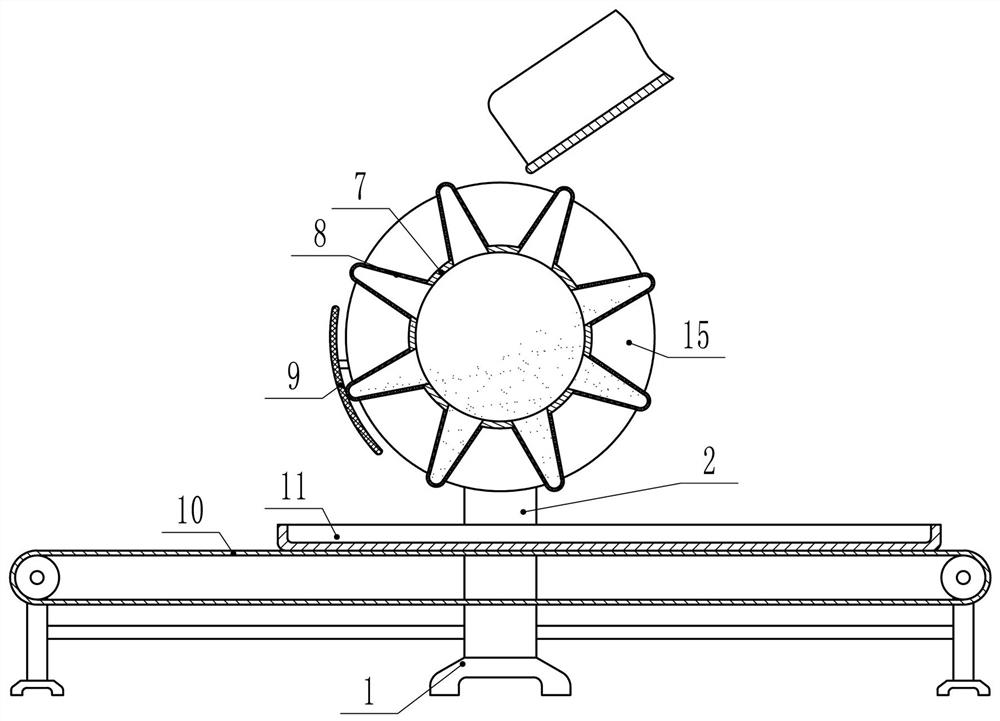

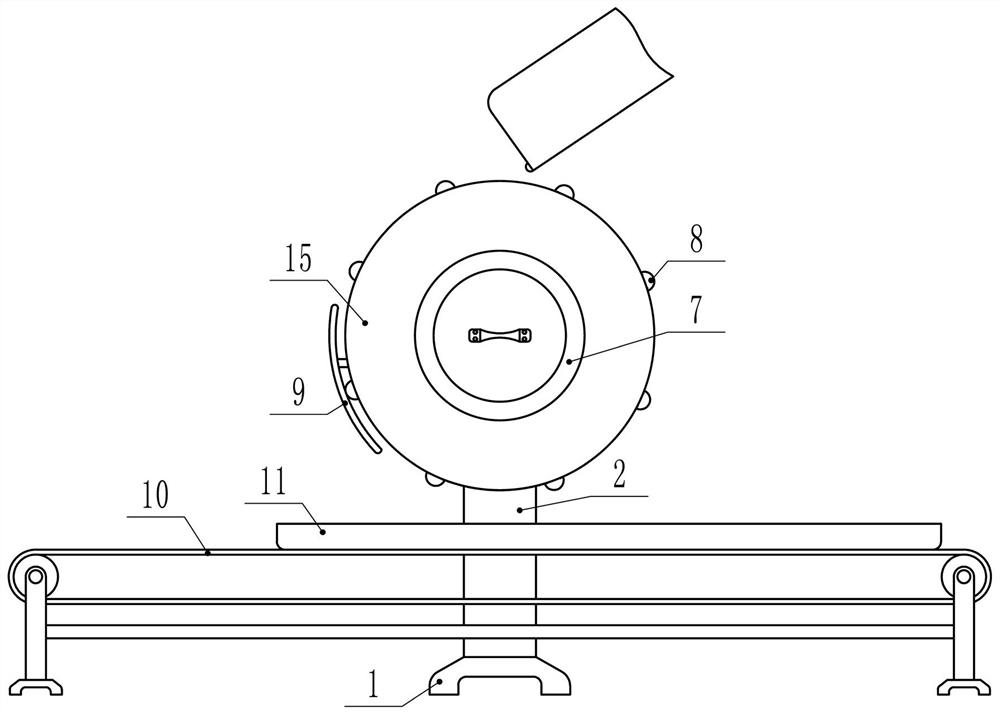

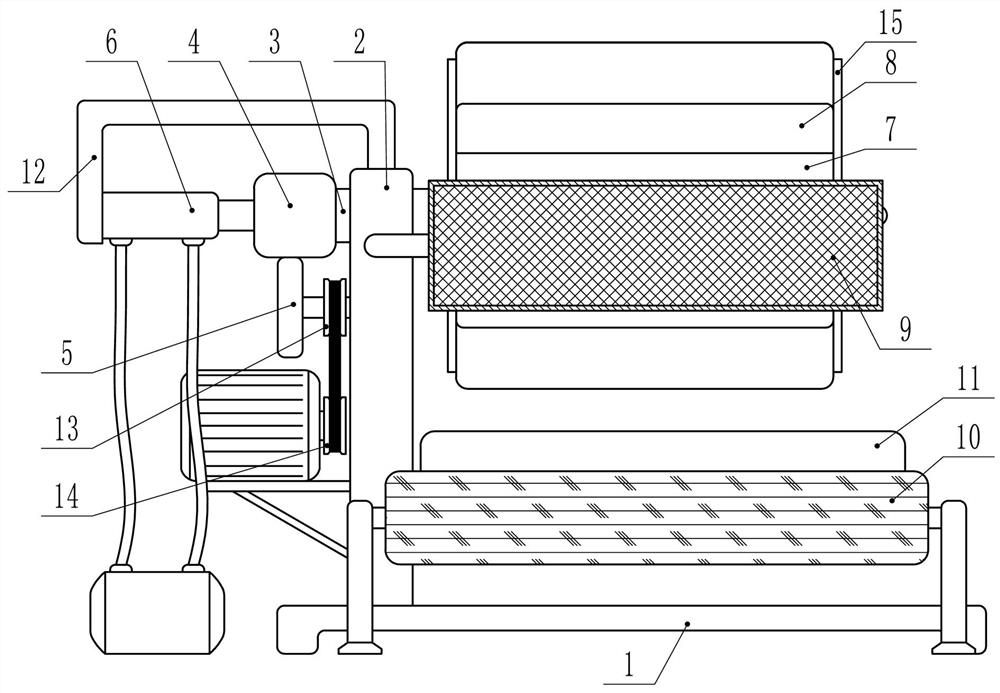

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Depend on Figure 1 to Figure 3 It can be seen that the present invention includes a base 1, a vertical plate 2 is fixed on the rear side of the base 1, the upper end of the vertical plate 2 is penetrated and connected with a rotating shaft 3 that can move left and right, and the part of the rotating shaft 3 placed on the rear side of the vertical plate 2 is the same as There is a first gear 4 fixed on the shaft, and a second gear 5 driven by a motor and always meshing with it is provided under the first gear 4. The rear end of the rotating shaft 3 is provided with a protruding end that can drive the rotating shaft 3 to reciprocate back and forth. The pneumatic push rod 6 connected with the rotating shaft 3 in rotation, the front end of the rotating shaft 3 is coaxially fixed with a cylinder 7, and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com