Novel oil screen and extractor hood with same

A technology of range hood and oil net, which is applied in the direction of removing oil fume, household appliances, and household stove/stove, etc., can solve the problems of the smoking port being far away from the countertop, rising oil fume, occupying a lot of space, etc., so as to improve the stability and reliability of the connection. Sex, increase the contact area, and improve the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

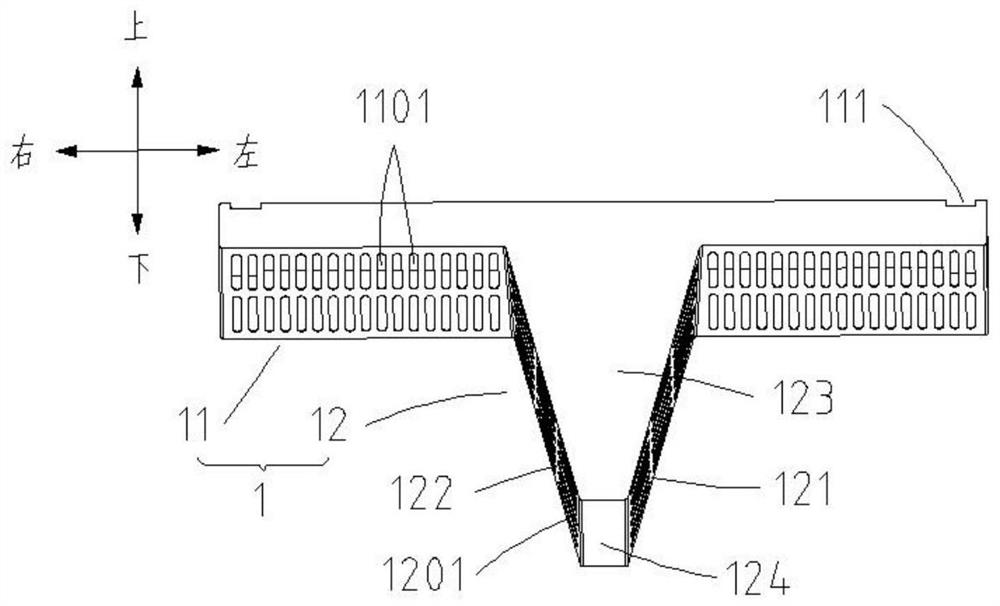

[0033] Such as Figure 1-3 As shown, this embodiment provides a new type of oil screen applied to range hoods, the new type of oil fume 1 includes a first oil screen 11 and a second oil screen 12, the first oil screen 11 is arranged along the horizontal direction, and the second The side of an oil net 11 facing the upward escape of the oil fume is provided with a number of jacking smoke holes 1101 for the oil fume to pass through, so that the oil fume escapes upwards and is sucked into the range hood through the jacking smoke holes 1101 of the first oil net 11. Form a top suction effect. The second oil screen 12 is arranged below the middle part of the first oil screen 11 to define the left and right smoke collection areas, and the second oil screen 12 has a left side 121, a right side 122 and a connecting surface 123. The side surfaces 122 are provided with a number of side smoke inlet holes 1201 for oil smoke to pass through. The left and right sides of the connection surfa...

Embodiment 2

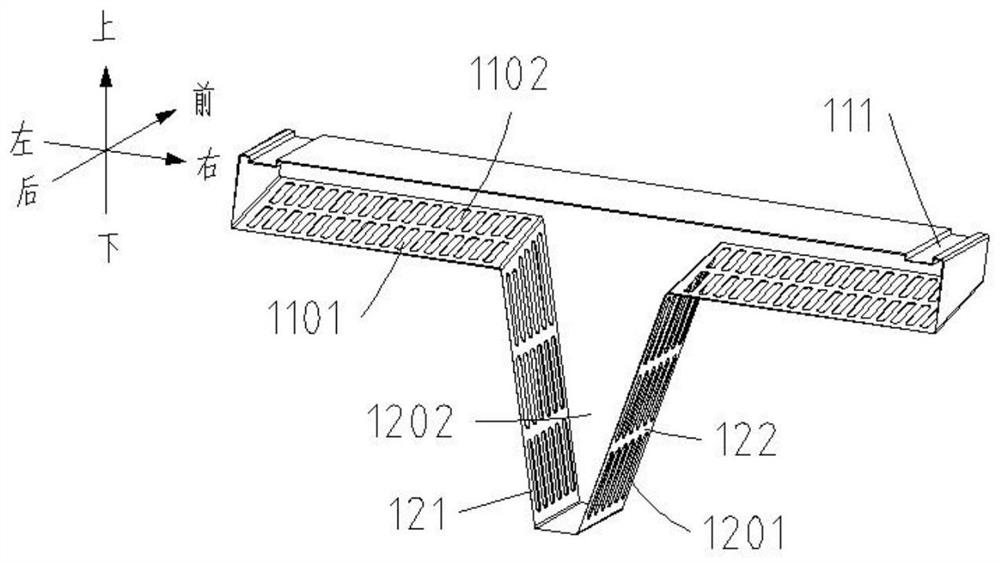

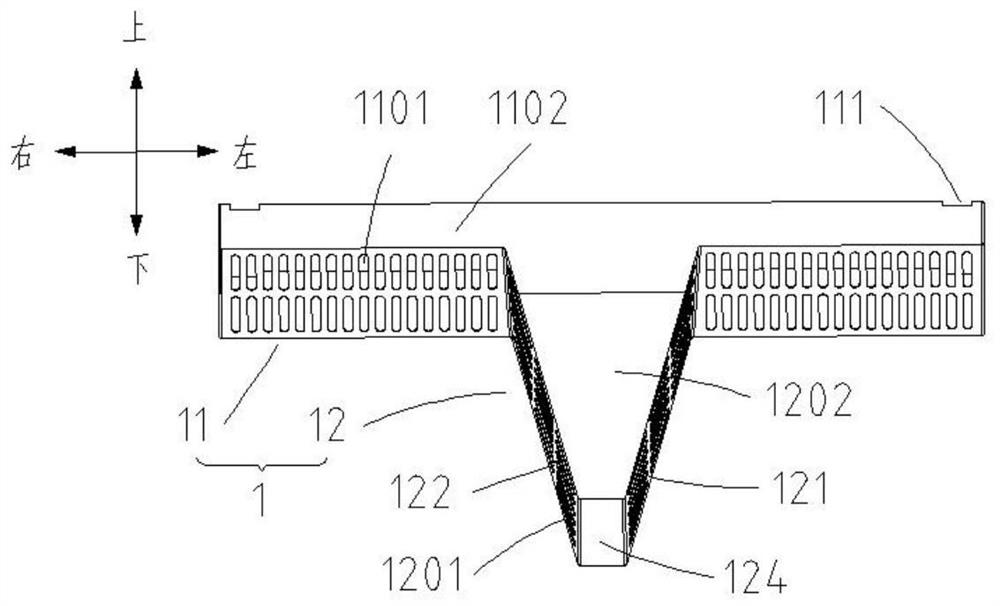

[0045] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the front of the novel oil screen is omitted. Specifically, horizontal openings 1102 are provided on the front and back of the first oil screen 11 , vertical openings 1202 are provided on the front and back of the second oil screen 12 , and the rest are the same as in Embodiment 4.

[0046] In practical application, the first oil screen 11 and the second oil screen 12 are respectively fixedly connected to the panel of the range hood, and the panel of the range hood covers the transverse opening 1102 on the front of the first oil screen 11 and the second oil screen 12, the vertical opening 1202 on the front makes the panels of the range hood constitute the fronts of the first oil net 11 and the second oil net 12, that is, constitute the front of the new oil net. In addition, the horizontal opening 1102 on the back of the first oil net 11 and the vertical opening 1202 on the back o...

Embodiment 3

[0049] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the specific structure of the new oil screen is different. Specifically, there are two second oil nets 12, and the two second oil nets 12 are respectively arranged at the left and right ends of the first oil net 11, so that the first oil net 11 and the second oil net 12 form a " ∏" shape to limit the smoke gathering area. On the right side 122 of the second oil net 12 on the left and on the left side wall of the second oil net 12 on the right, a number of evenly spaced side smoke inlet holes 1201 are arranged, and the side smoke inlet holes 1201 are also vertically long. The strip holes are conducive to shortening the distance between the lowest side smoke entry hole 1201 and the cooktop.

[0050] It can be seen that the two second oil nets 12 and the first oil net 11 enclose a smoke-collecting area, and the two second oil nets 12 can shorten the distance between the smoke inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical depth | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com