Butt joint type range hood

A range hood, docking technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of smoke easily escaping to the outside, difficult to completely remove oil fume, time-consuming and laborious, etc., to improve the effect of smoke exhaust, The effect of reducing the volume of the smoke shell and improving the smoke collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

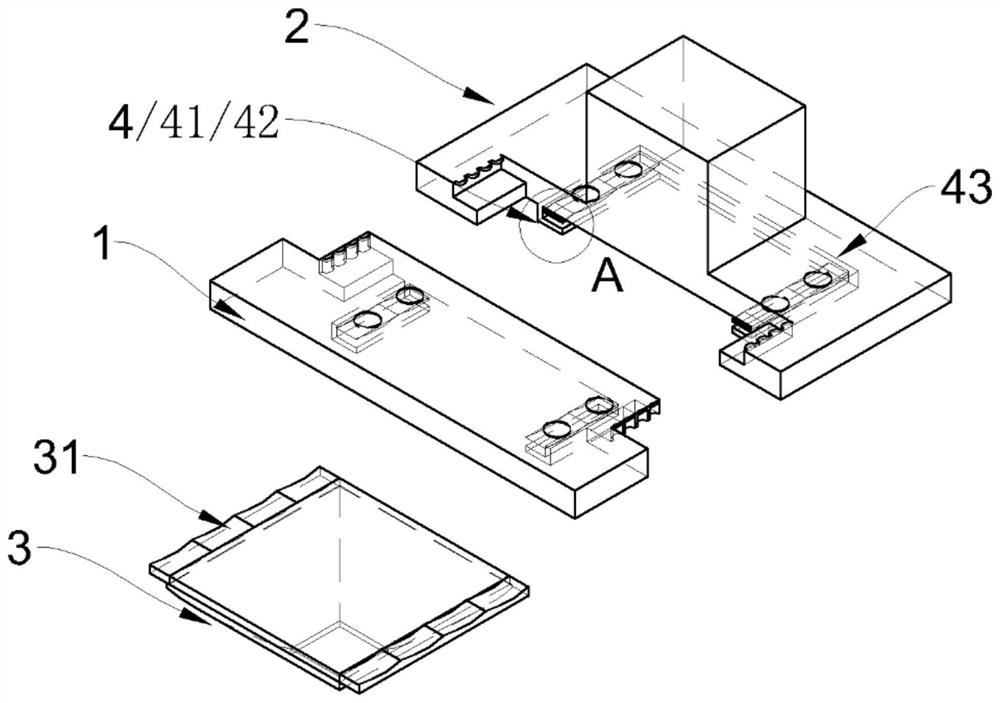

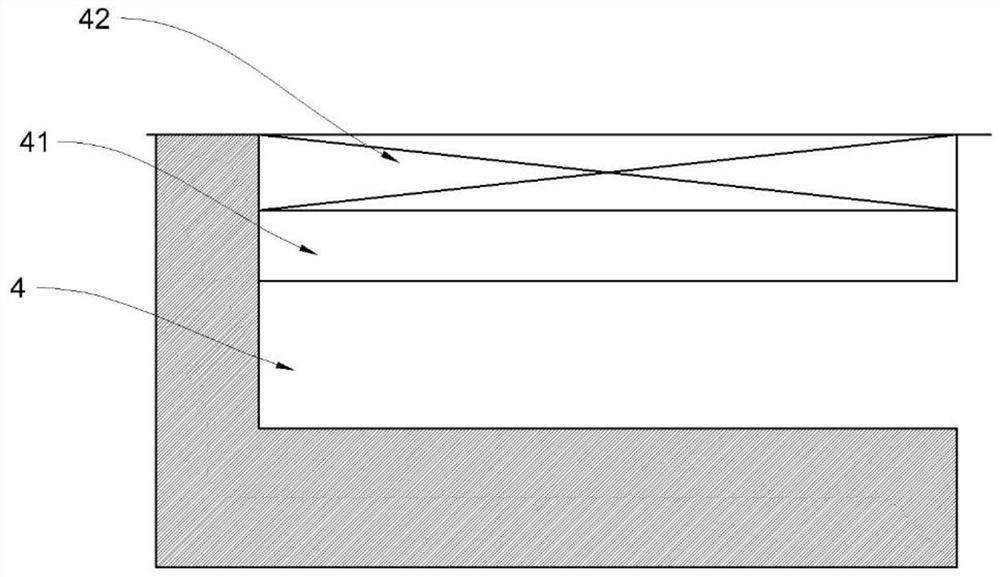

[0029] Such as Figure 1-Figure 3 Shown: a docking range hood, including the first half body 1, the second half body 2, the filter system 3 (the filter system 3 includes the filter screen in the mesh cover); the operation panel is located in the first half body 1 Above; the smoke exhaust pipe, fan system, and power system are located in the second half body 2, and the second half body 2 is fixed on the wall; There is an electrical docking interface between the operation panel and the power system (if the operation panel connected to the power system is placed on the second half body 2, there is no need to add a docking interface, this embodiment is designed for the purpose of facilitating user operation) ; The outer surface of the first half body 1 and the second half body 2 is docked to form a slot 4 for the filter system 3 to be plugged into the cigarette port.

[0030] During installation, the second half body 2 is fixedly installed on the wall first, the first half body 1...

Embodiment 2

[0034] Such as Figure 4-Figure 6 As shown, this embodiment is optimized on the basis of Embodiment 1, so that the range hood can achieve an excellent smoke exhaust effect.

[0035] details as follows:

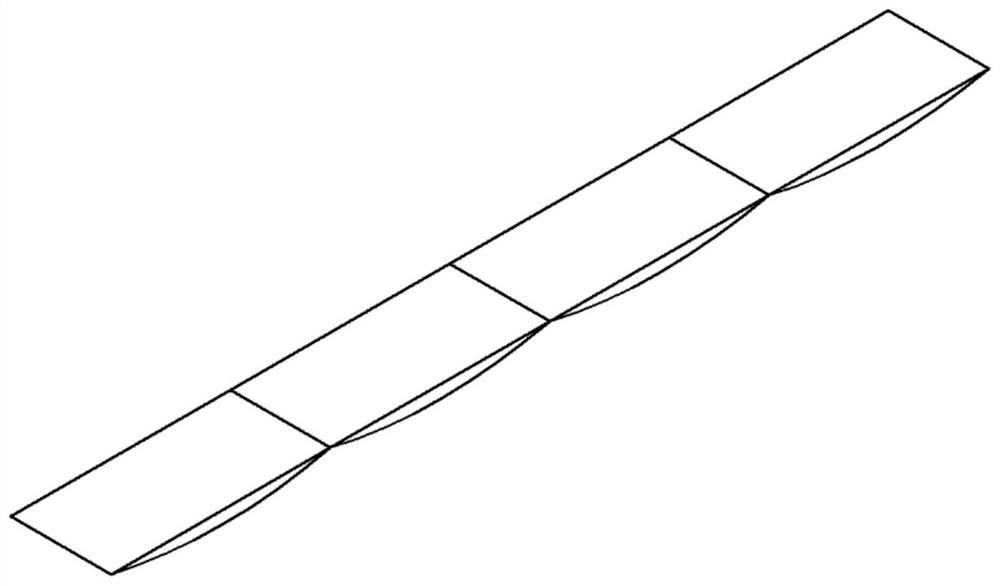

[0036] (1) Both sides of the bottom of the second half body 2 extend downward to form arc-shaped smoke collecting plates 21 .

[0037] (2) The smoke collecting plate 21 is provided with an electromagnetic heating component 21.1 activated by an external power supply.

[0038] ⑶. The electromagnetic heating assembly 21.1 is provided with a heat conducting gasket 21.2 and a heat sink 21.3 in sequence toward the inner surface of the smoke collecting plate 21.

[0039] The slope at the bottom of the housing composed of two halves forms a channel for the smoke to move to the central smoke port. The structure of the smoke collecting plate 21 enables the smoke on both sides to be "collected", which greatly reduces the possibility of the smoke floating to the outside of the range ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com