High performance extractor hood

A range hood, high-performance technology, applied in the field of kitchen appliances, can solve problems such as loud noise, unsmooth air outlet, chaotic airflow direction, etc., to achieve the effect of reducing noise, smooth airflow, and reducing airflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

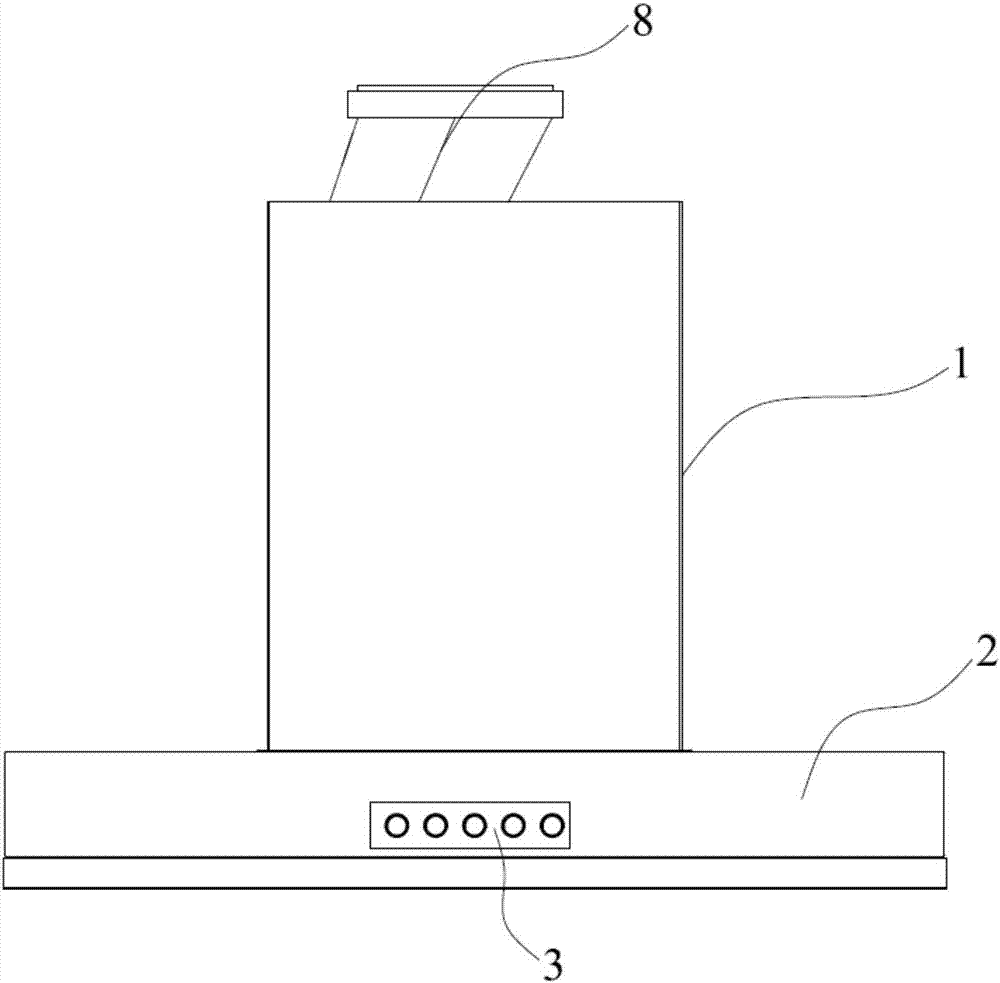

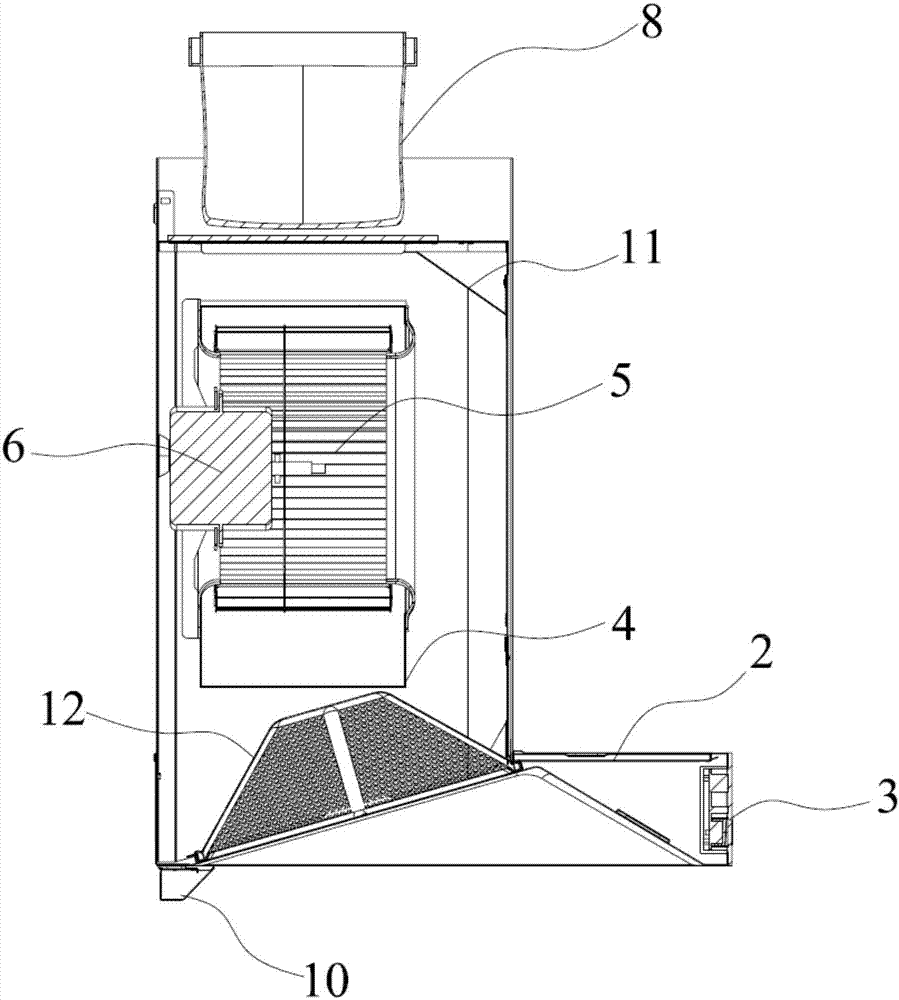

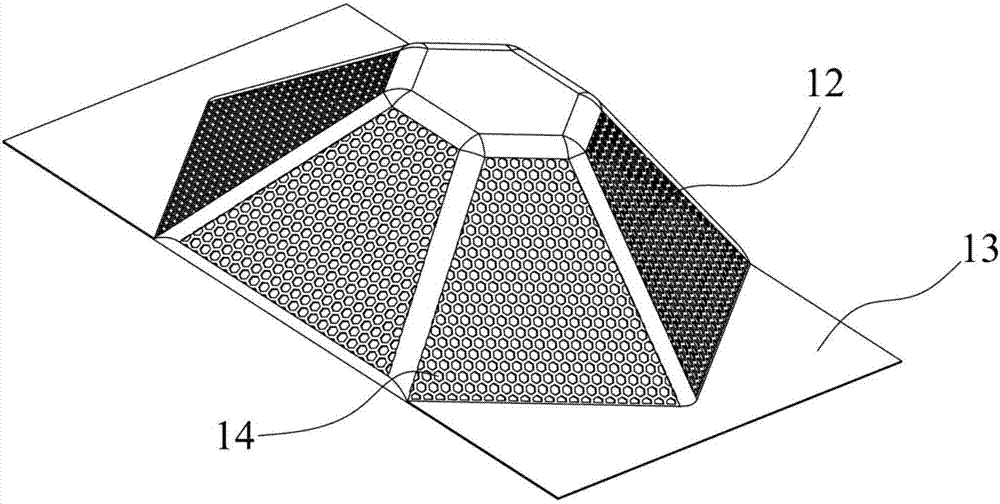

[0033] like figure 1 , figure 2 The shown high-performance range hood includes a chassis 1, a fume collecting hood 2 located at the bottom of the chassis and communicated with the chassis, and a centrifugal fan system disposed in the chassis. A control display panel 3 is installed on the front side of the fume collecting hood. , an oil collecting assembly is arranged in the fume collecting hood, an oil cup 10 is arranged at the bottom of the side of the fume collecting hood away from the control display panel, and an oil collecting plate 11 is arranged along the length of the case at the corner position of the top of the chassis close to the control display panel. The oil collecting assembly includes the oil collecting metal mesh plate 12 and the oil guide plate 13 (see image 3 ), the oil-collecting metal mesh plate is a regular hexagonal struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com