Symmetric prestressed steel wire winding process

A technology of prestressed steel wire and winding process, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of long cycle and slow winding rhythm, and achieve the effect of reducing winding time and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

[0017] A kind of symmetrical prestressed steel wire winding process provided by the present invention, the steps are as follows:

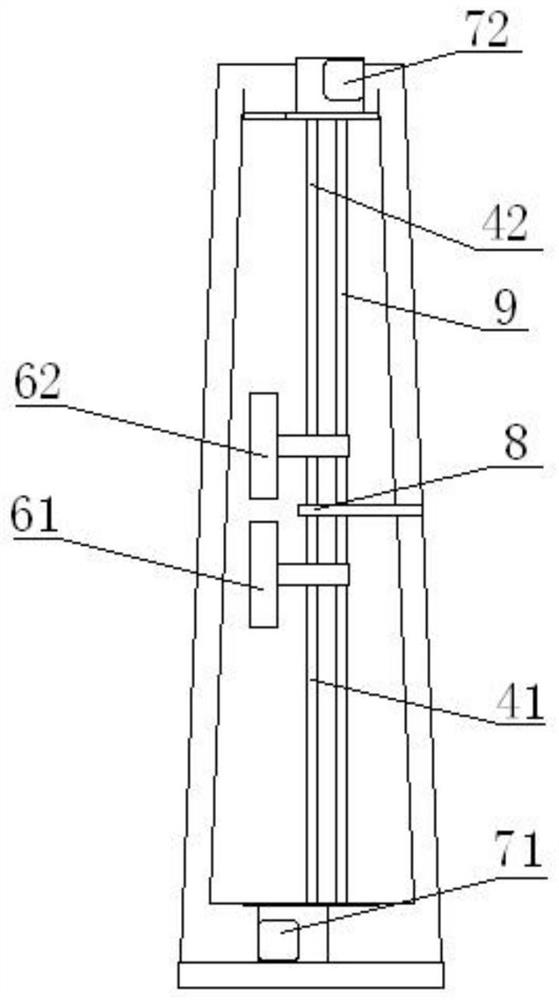

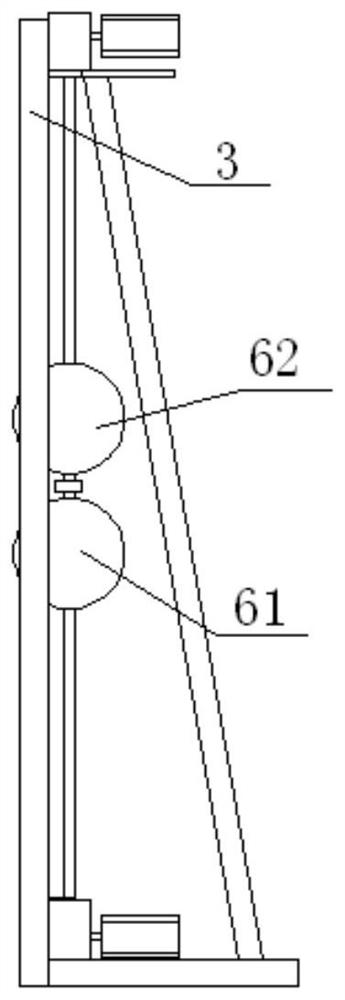

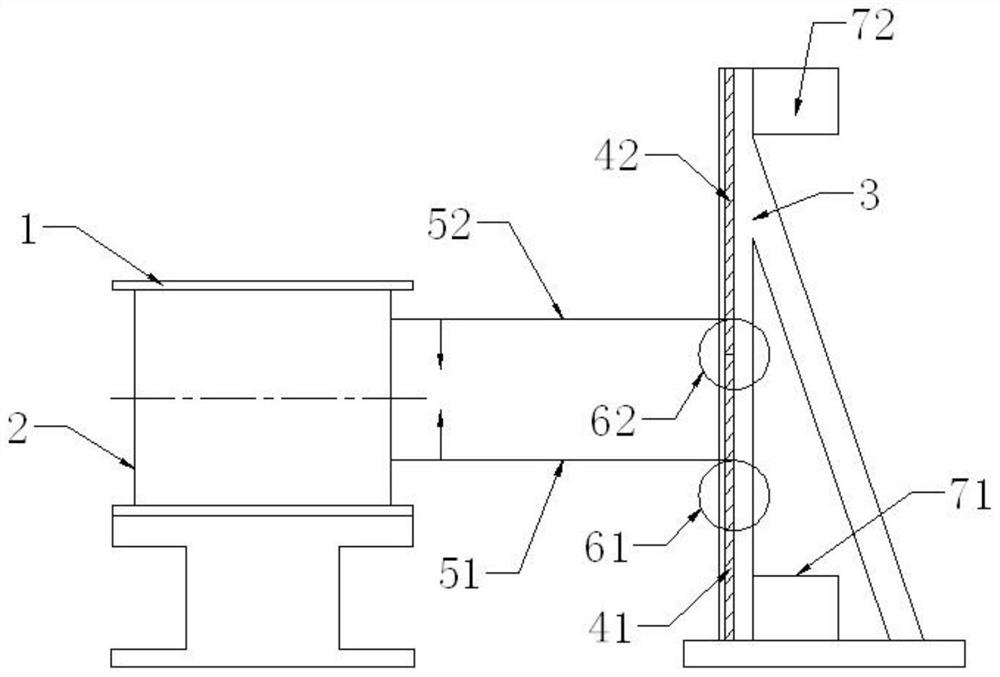

[0018] S1. Set the starting positions of the two steel wires respectively at the upper and lower ends of the steel wire groove 2 of the equipment to be wound;

[0019] S2. Each steel wire is connected to a pay-off device, the pay-off device is flush with the starting position of the steel wire, and the two drive motors start to run forward at the same time, driving the two pay-off devices to move. Relative movement to the center line;

[0020] S3. When the two steel wires are wound to the position of the center line of the steel wire groove 2, the two driving motors change from forward rotation to reverse rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com