Steel sleeper suitable for large-gradient rail and arrangement structure thereof

A technology with large slope and steel rails, which is applied in the field of steel sleepers, can solve the problems of insufficient vertical and horizontal resistance of the track, difficulty in maintaining the geometric shape of the line, and weak connection, so as to achieve good vertical and horizontal stability, reduce bad risks, and increase grip effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] In order to be able to more clearly understand the above objectives, features and advantages of the present disclosure, the solutions of the present disclosure will be further described below. It should be noted that the embodiments of the present disclosure and the features in the embodiments can be combined with each other if there is no conflict.

[0027] In the following description, many specific details are set forth in order to fully understand the present disclosure, but the present disclosure can also be implemented in other ways different from those described here; obviously, the embodiments in the specification are only a part of the embodiments of the present disclosure. Not all examples.

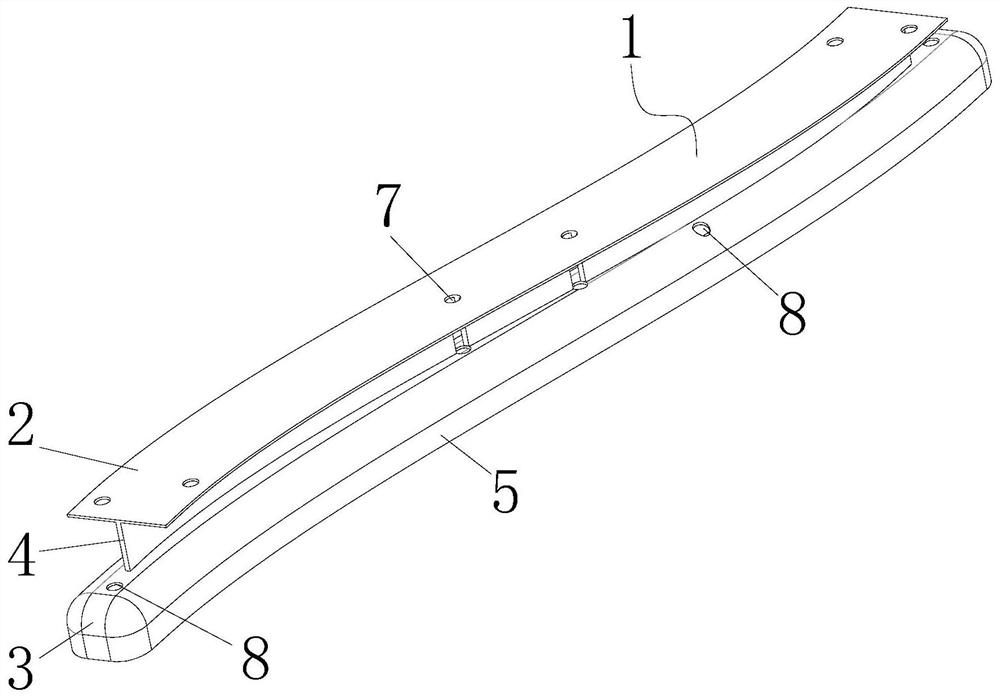

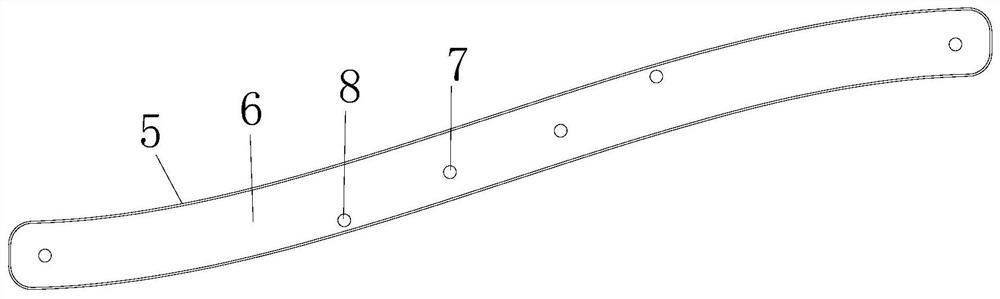

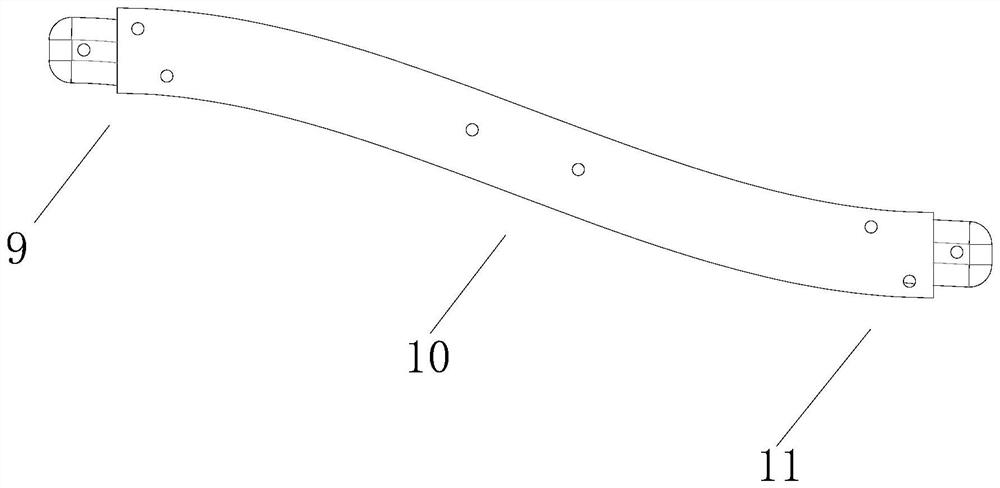

[0028] In some embodiments, see figure 1 with figure 2 , The present disclosure provides a steel sleeper suitable for a steeply sloped track, including a first steel sleeper 1, the first steel sleeper 1 includes a top steel plate 2 for supporting the rail 2, a bottom steel pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap