Patents

Literature

51results about How to "Reduce the risk of bad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

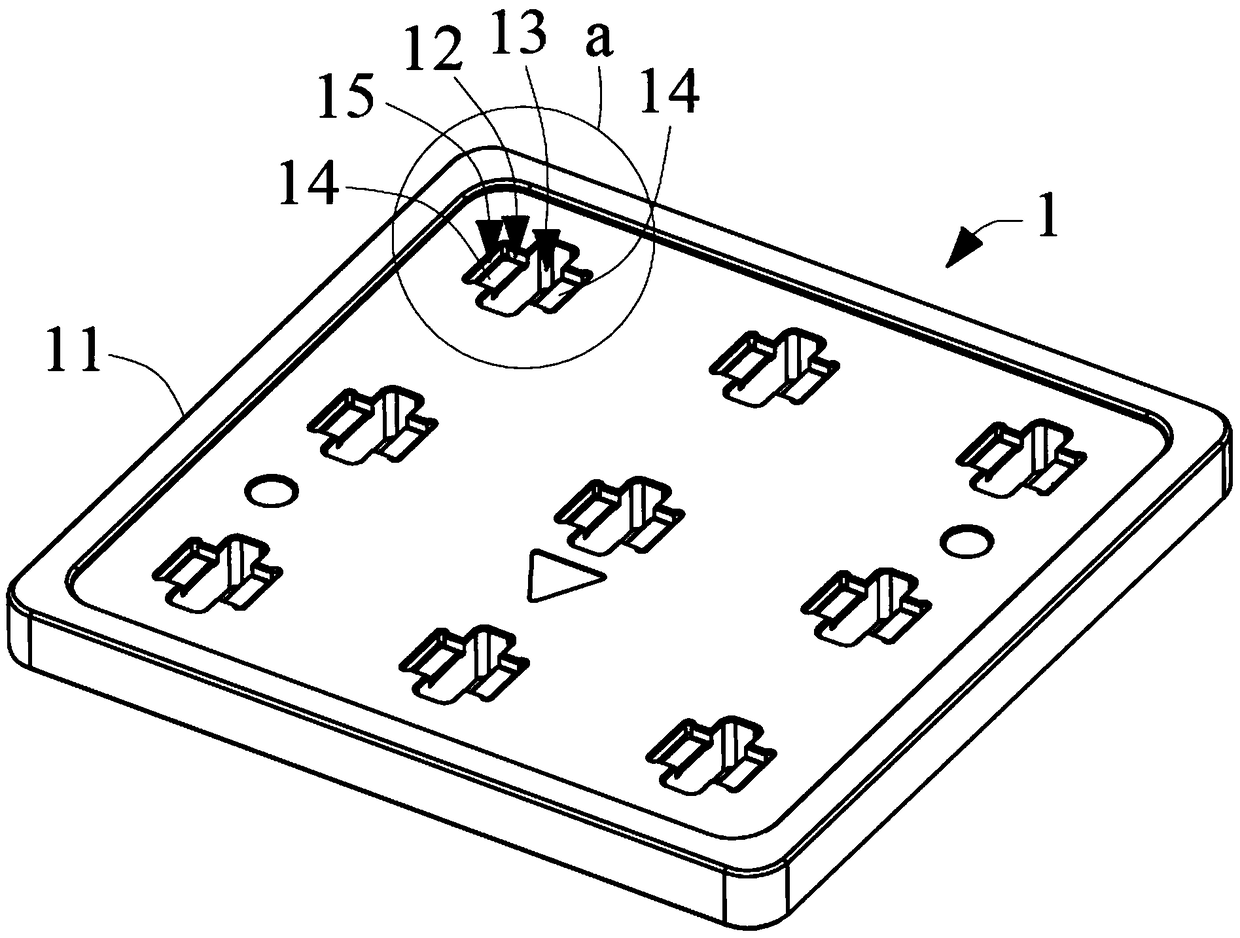

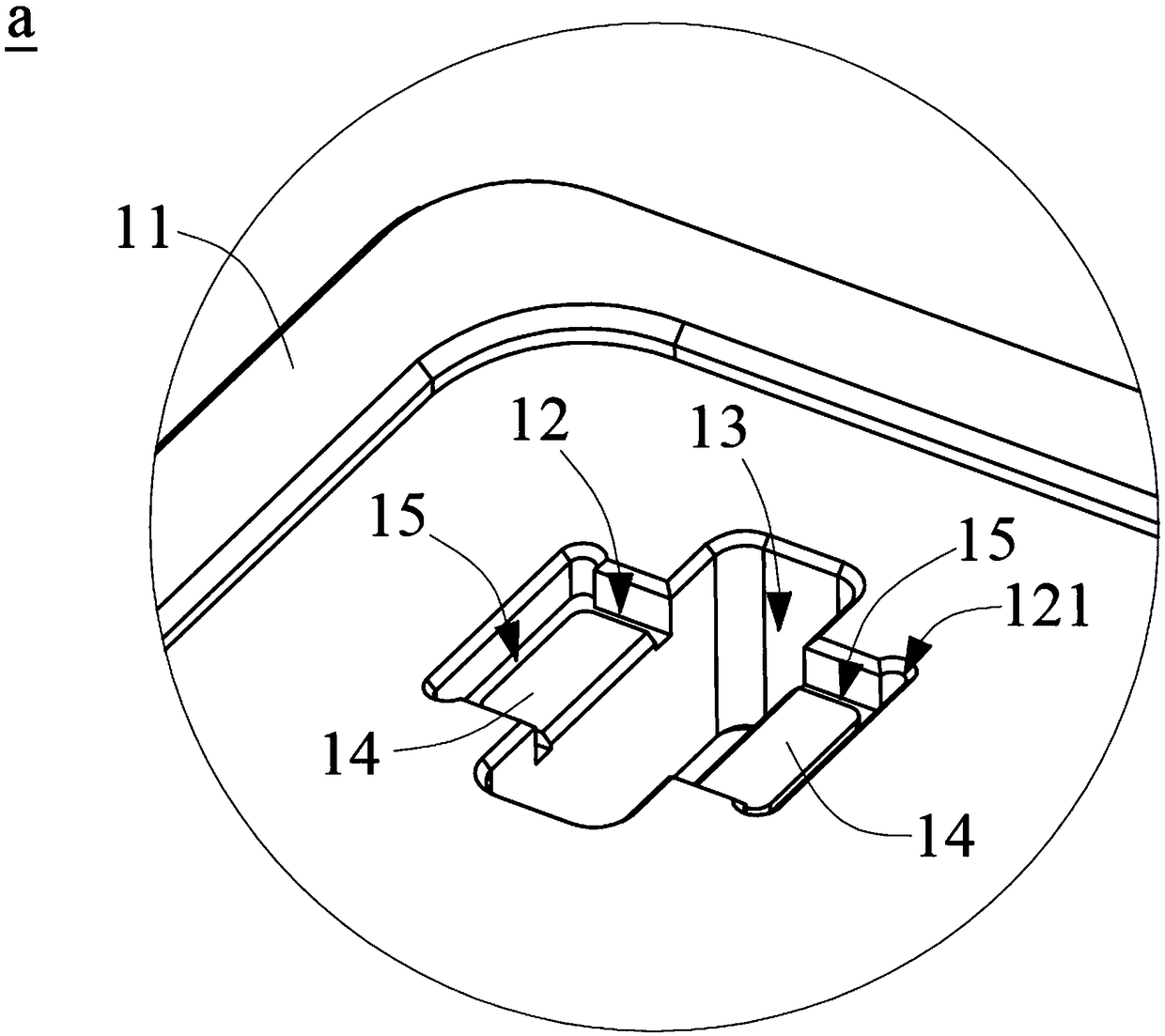

Display substrate, manufacturing method thereof, crack detection method and display device

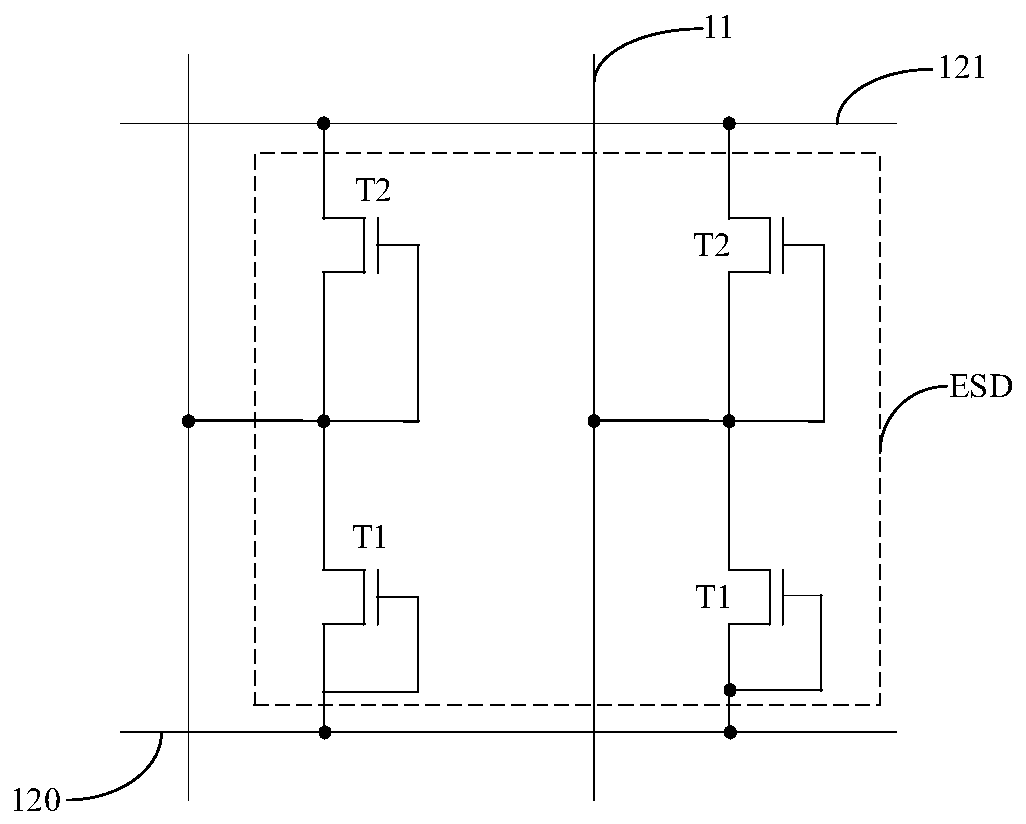

ActiveCN109935571AEasy to detectEfficient detectionElectronic circuit testingSemiconductor/solid-state device detailsData signalDisplay device

The invention discloses a display substrate, a manufacturing method thereof, a crack detection method and a display device, relates to the technical field of display, and aims at solving the problemsthat an existing crack detection mode is complex in operation and wiring difficulty in an edge area of a display screen is easily increased. The display substrate comprises a pixel unit and a data signal line, wherein the data signal line is used for writing a data voltage signal into the pixel unit. The display substrate further comprises an electrostatic discharge circuit, and the electrostaticdischarge circuit comprises a first electrostatic discharge line and a second electrostatic discharge line; a first electrostatic discharge sub-circuit which is connected with the data signal line andthe first electrostatic discharge line, wherein a connecting line included in the first electrostatic discharge sub-circuit is reused as a crack detection line, and the crack detection line is located in a peripheral area, surrounding the display area, in the display substrate and extends along the edge of the display substrate. The first electrostatic discharge sub-circuit is used for conductingthe connection between the data signal line and the first electrostatic discharge line when the crack detection line is broken in a detection period. The display substrate provided by the invention is used for displaying.

Owner:BOE TECH GRP CO LTD +1

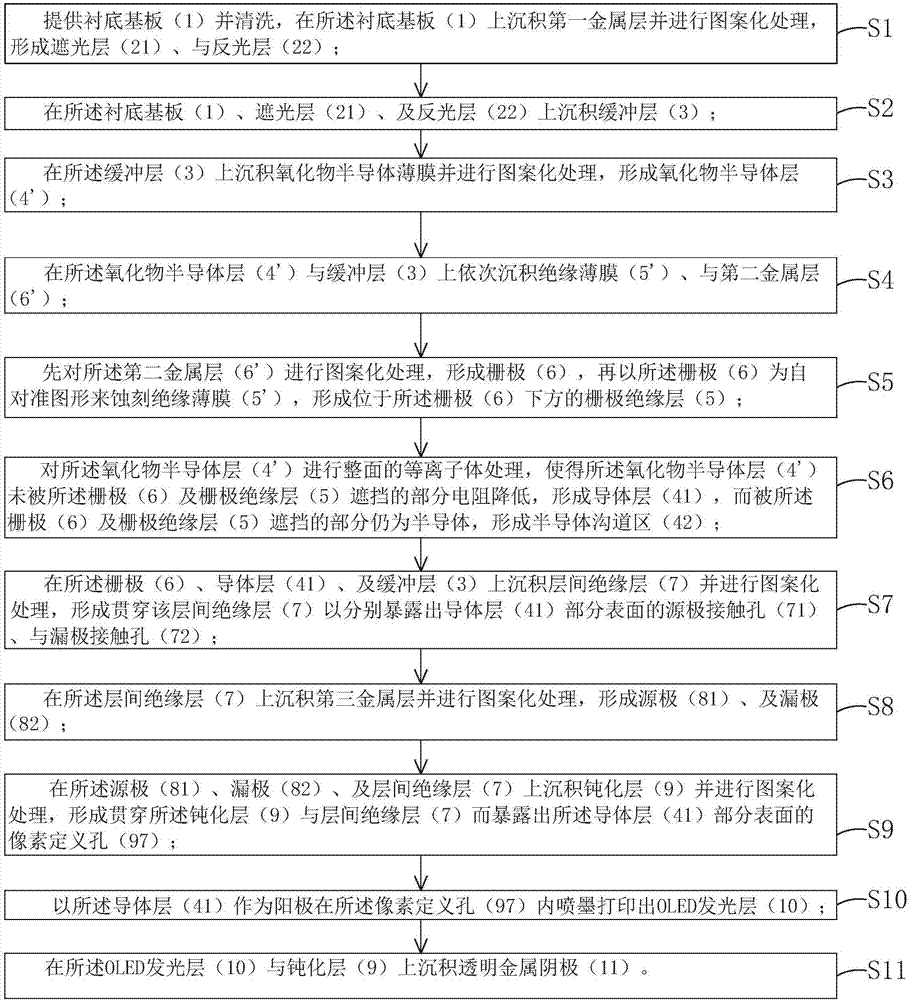

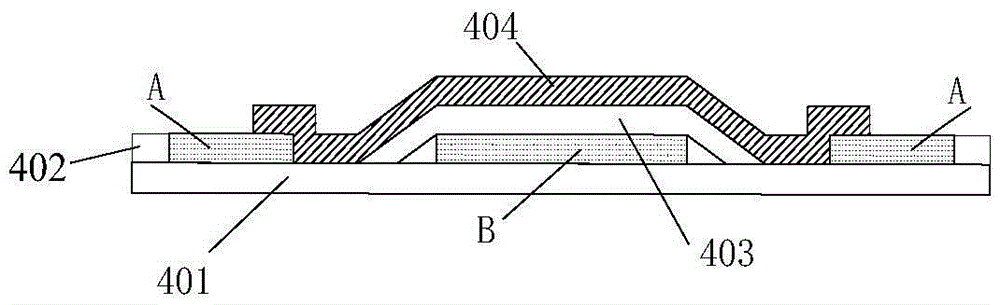

Top-emitting-type OLED panel manufacturing method and structure thereof

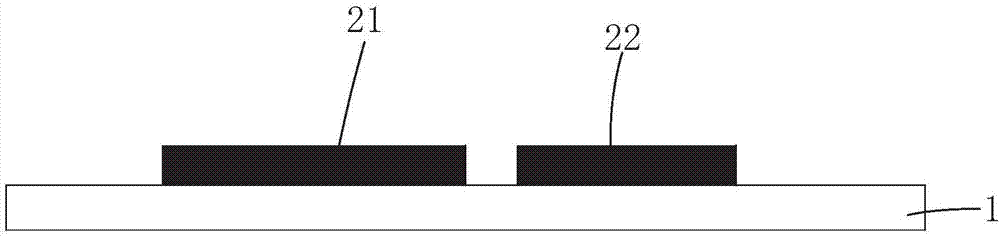

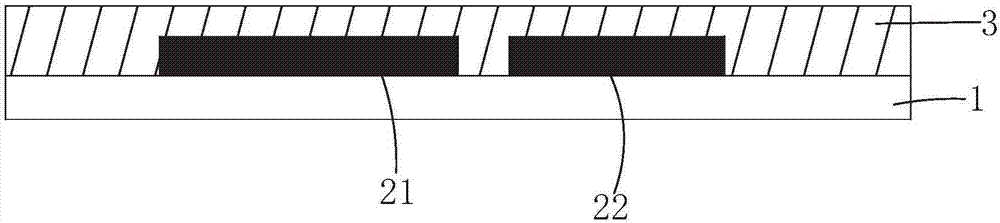

InactiveCN107293554ASimple structureSimple manufacturing processTransistorSolid-state devicesInsulation layerManufacturing technology

The present invention provides a top-emitting-type OLED panel manufacturing method and the structure thereof. In the top-emitting-type OLED panel manufacturing method, through the patterned treatment of a first metal layer, a light blocking layer and a light reflecting layer are fabricated, which simplifies the manufacturing technology for an anode and reduces the risk for bad problems. After a gate electrode and a gate electrode insulation layer are fabricated on an oxide semiconductor layer, plasma treatment is performed on the entire surface of the oxide semiconductor layer so that the part of the oxide semiconductor layer not covered by the gate electrode and the gate electrode insulation layer is reduced in resistance and forms a conductor layer, while the part blocked by the gate electrode and the gate electrode insulation layer is still a semiconductor and forms a semiconductor channel region. The conductor layer is used as the anode of a white light OLED, which can eliminate yellow light for fabricating the anode independently and an etching process. In addition, the fabrication of a traditional flattening layer and a pixel defining layer can both be eliminated, therefore, reducing the number of procedures for yellow light fabricating, reducing the number of light covers and cutting the fabricating cost. The use of an ink-jet printing OLED light-emitting layer further keeps the manufacturing cost down.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

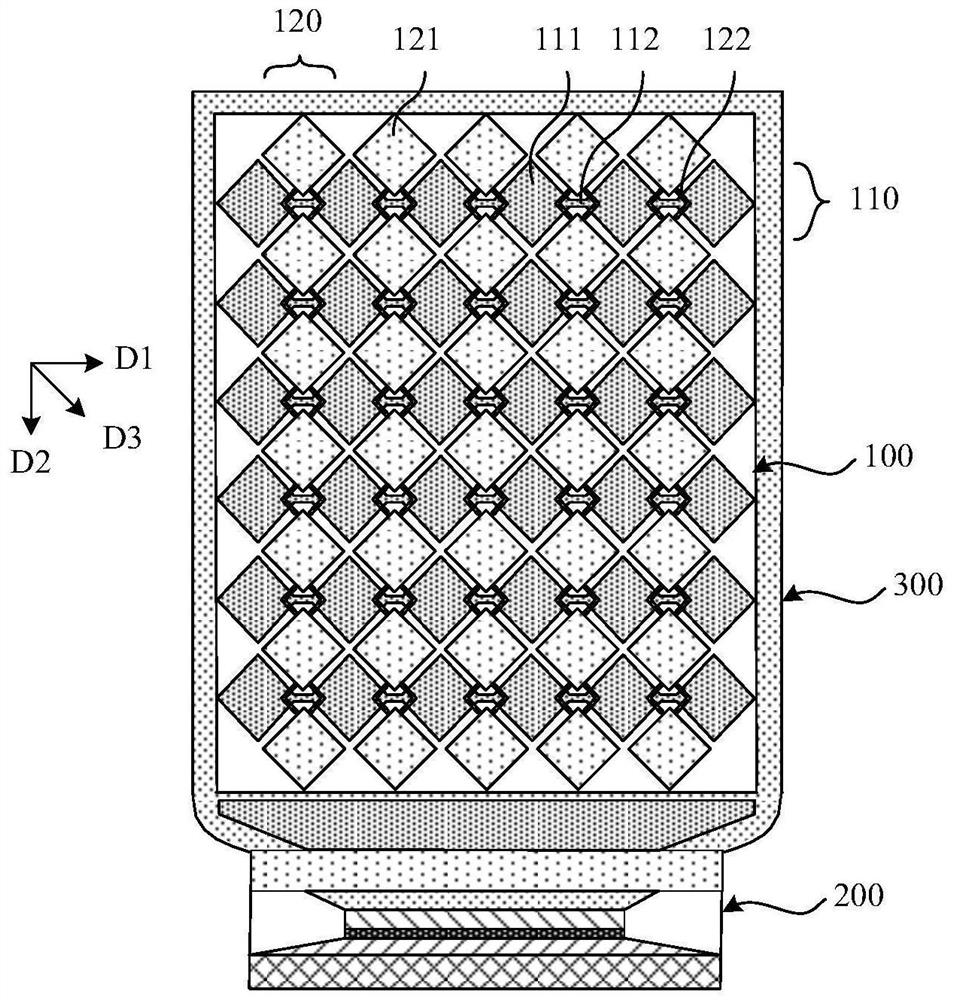

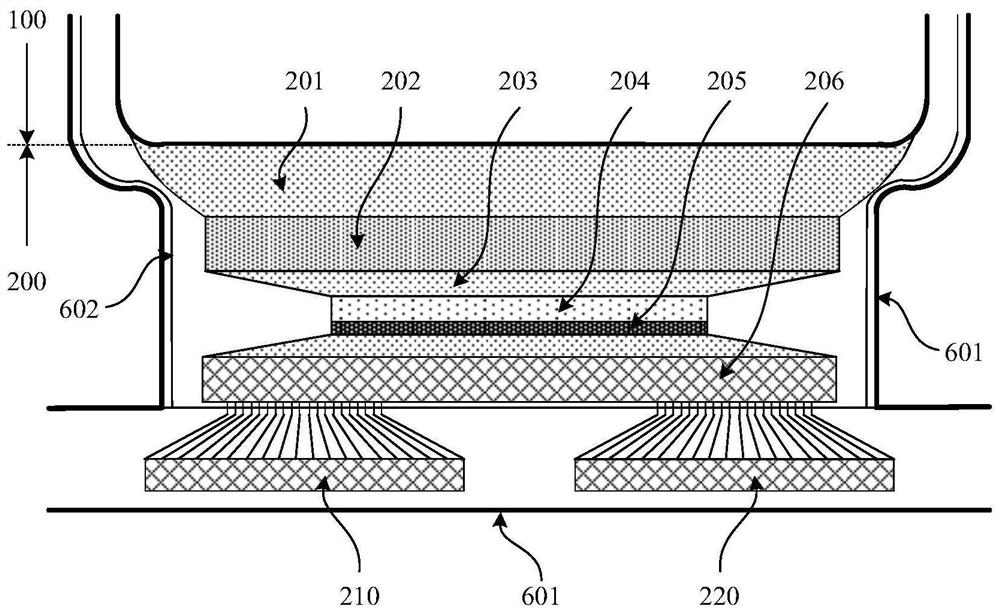

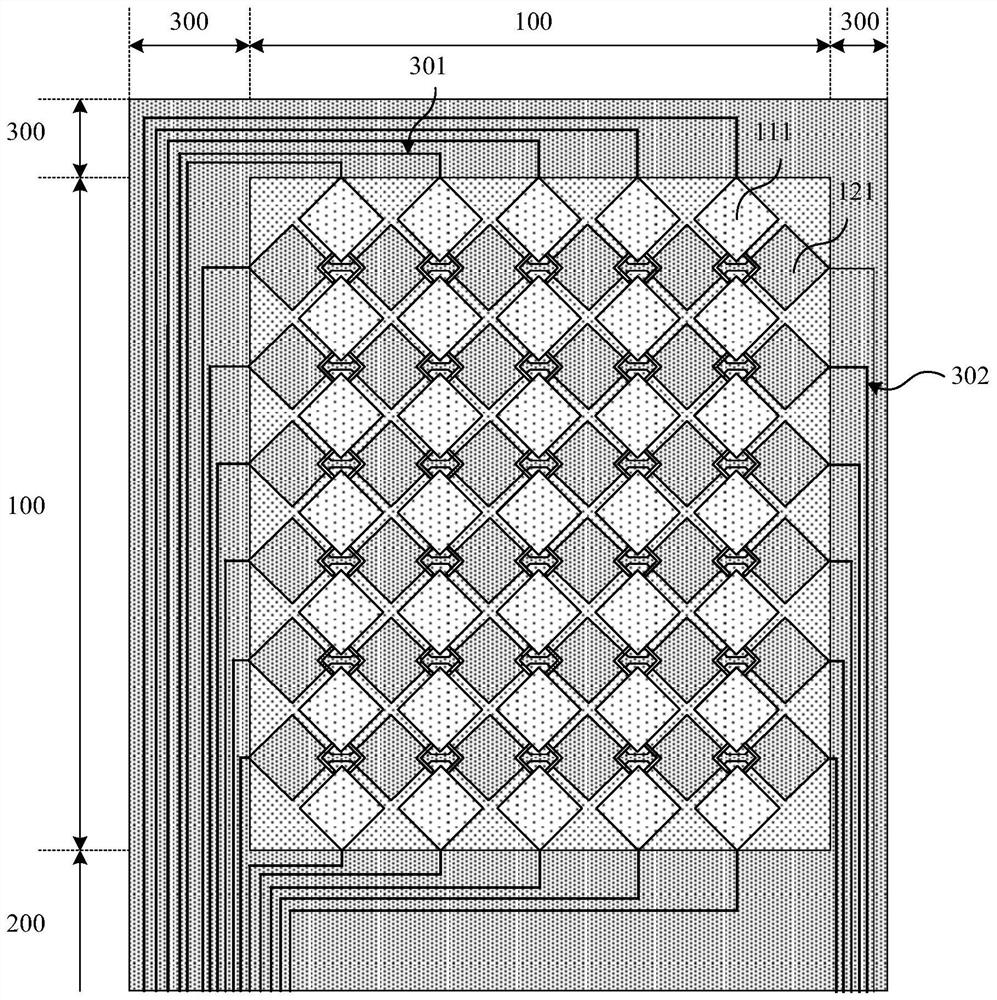

Touch panel and preparation method thereof and display device

PendingCN112035013AReduce in quantityReduce the risk of badSolid-state devicesInput/output processes for data processingDisplay deviceMechanical engineering

The invention discloses a touch panel and a preparation method thereof and a display device. The touch panel comprises a touch area, a binding area located on one side of the touch area and an edge area located on the other side of the touch area. The touch area at least comprises M rows of first touch units and N columns of second touch units, the binding area at least comprises a binding pin area, and the edge area at least comprises a plurality of touch leads; and the first ends of the plurality of touch leads are respectively and correspondingly connected with the M rows of first touch units and the N columns of second touch units, and the second ends of the plurality of touch leads extend to the binding area and are correspondingly connected with the plurality of pins of the binding pin area, wherein M and N are positive integers greater than 2. According to the invention, the implementation cost and the production cost are effectively reduced.

Owner:BOE TECH GRP CO LTD +1

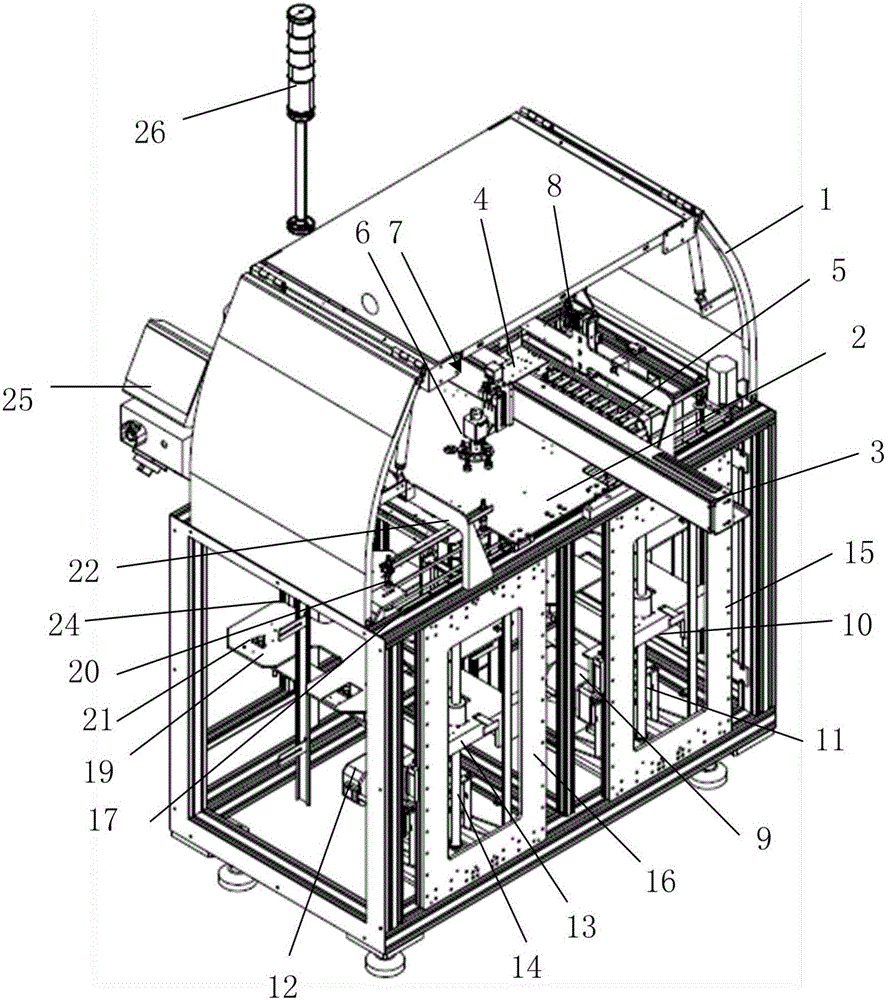

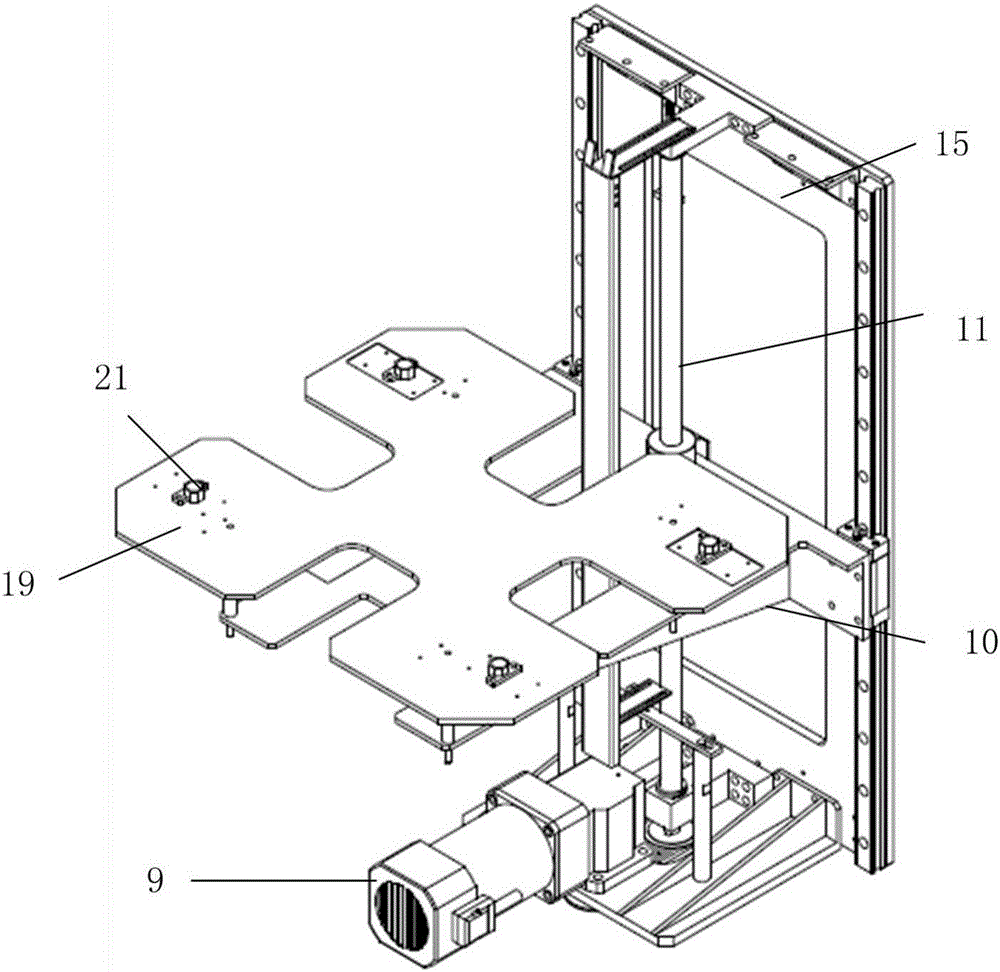

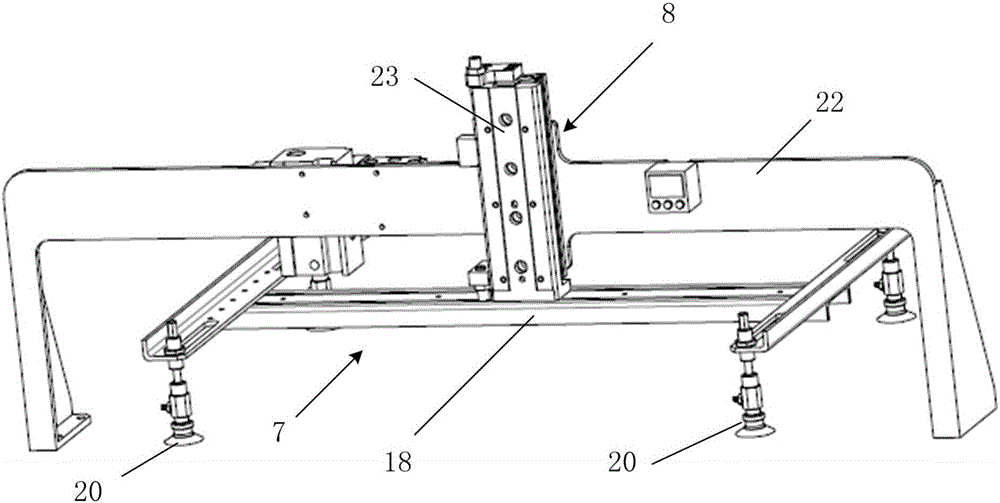

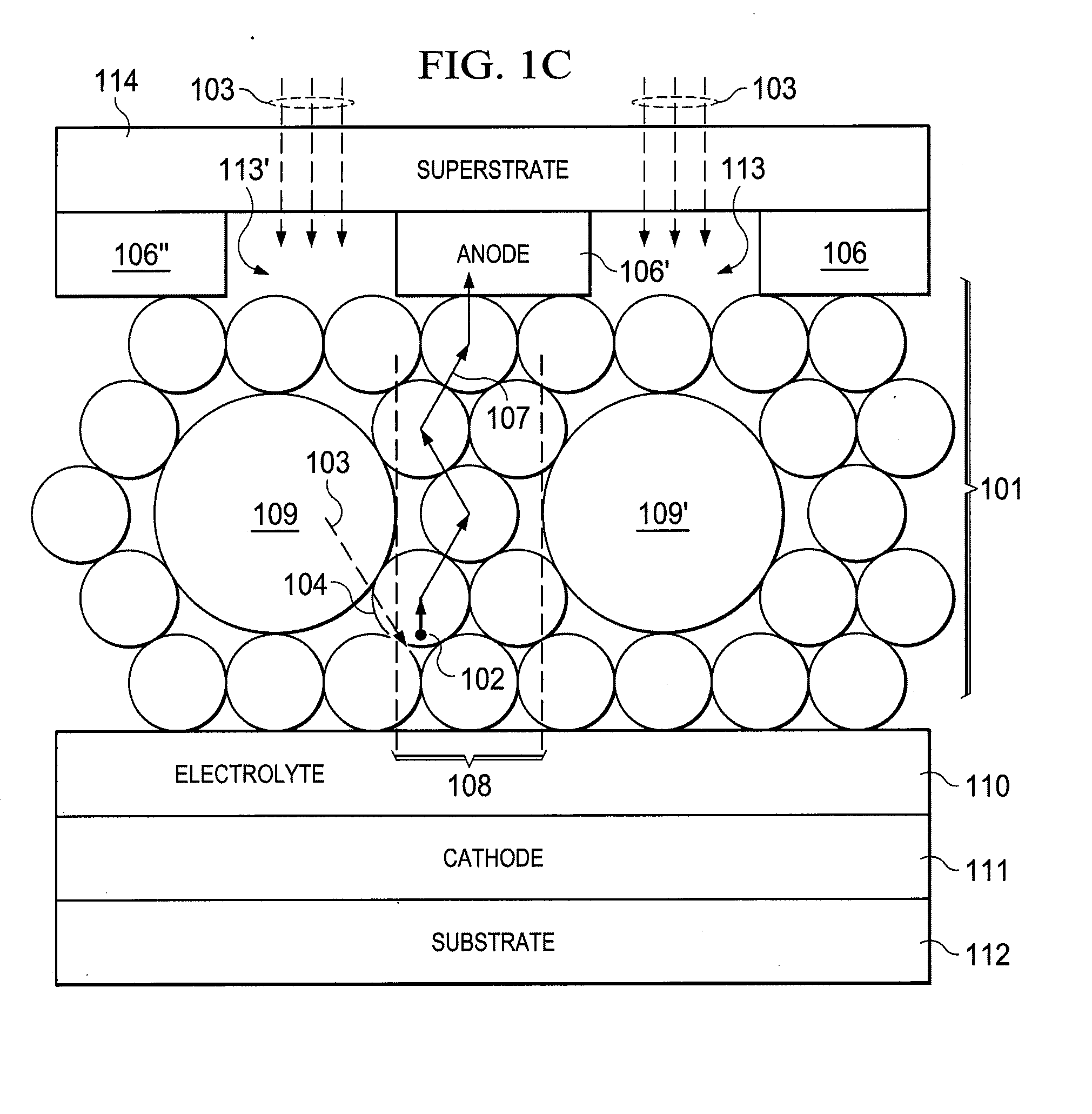

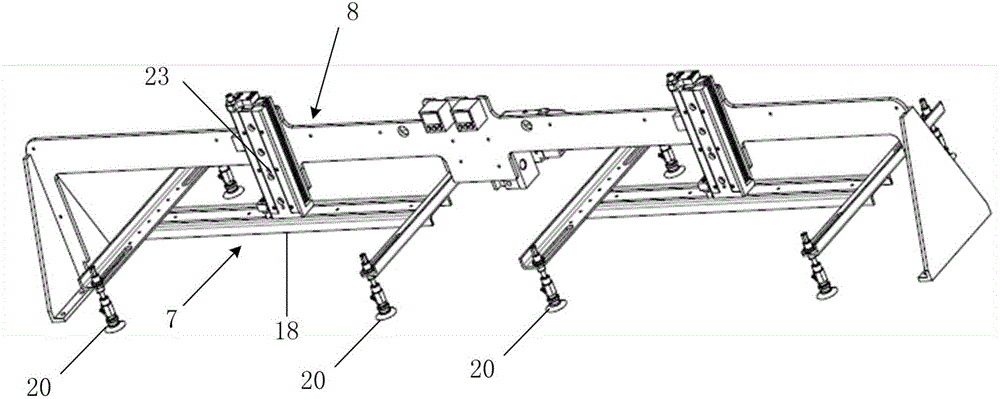

Single body feeding and discharging machine for manufacturing LCD products

InactiveCN105692199AReduce defective rateReduce the risk of badConveyorsConveyor partsProduction lineEngineering

The invention relates to a single loading and unloading machine for the manufacture and processing of LCD products, comprising a loading and unloading frame and a lifting unit, a suction unit and a conveying unit arranged in the loading and unloading frame, and the suction unit and the lifting unit are arranged There is a sliding platform that moves in the horizontal direction. The conveying unit includes a conveying shaft and a matching slider. One end of the slider is connected to the mechanical arm and the other end is connected to the suction device. The lifting unit includes a motor mechanism and a lifting platform mechanism for placing the feeding tray. and a sliding shaft mechanism, the motor mechanism drives the lifting platform mechanism to move up and down along the sliding shaft mechanism, and the suction unit includes a suction cup mechanism and a cylinder mechanism that drives the suction cup mechanism to move. The device of the invention can make the operator and the product zero-contact, can effectively reduce the defective rate of the product, improve the production efficiency of the product, and meet the requirements of loading and unloading in various links of the LCD product production line, thereby saving manpower and reducing product cost.

Owner:SUZHOU PROTECH PRECISION IND CO LTD

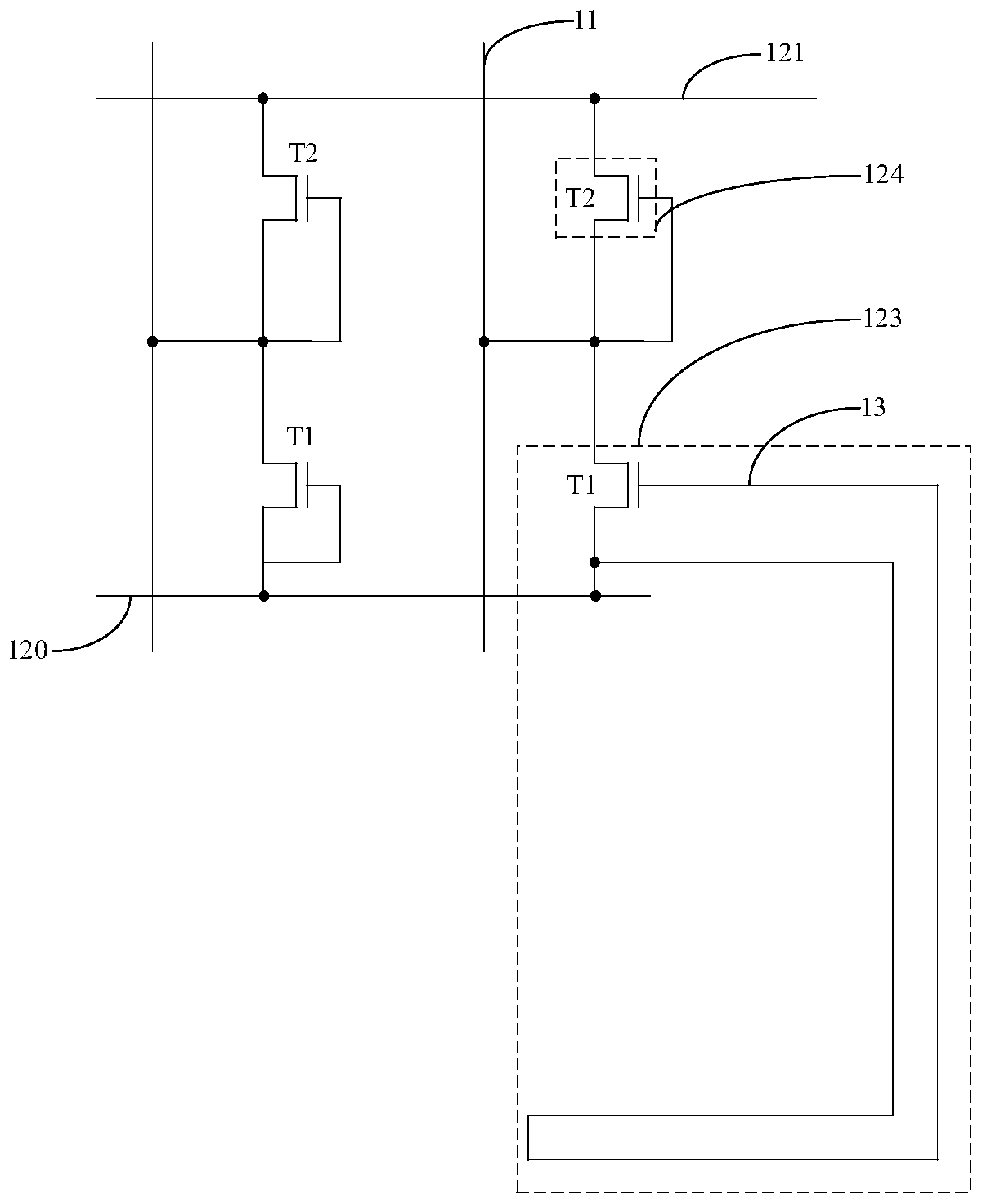

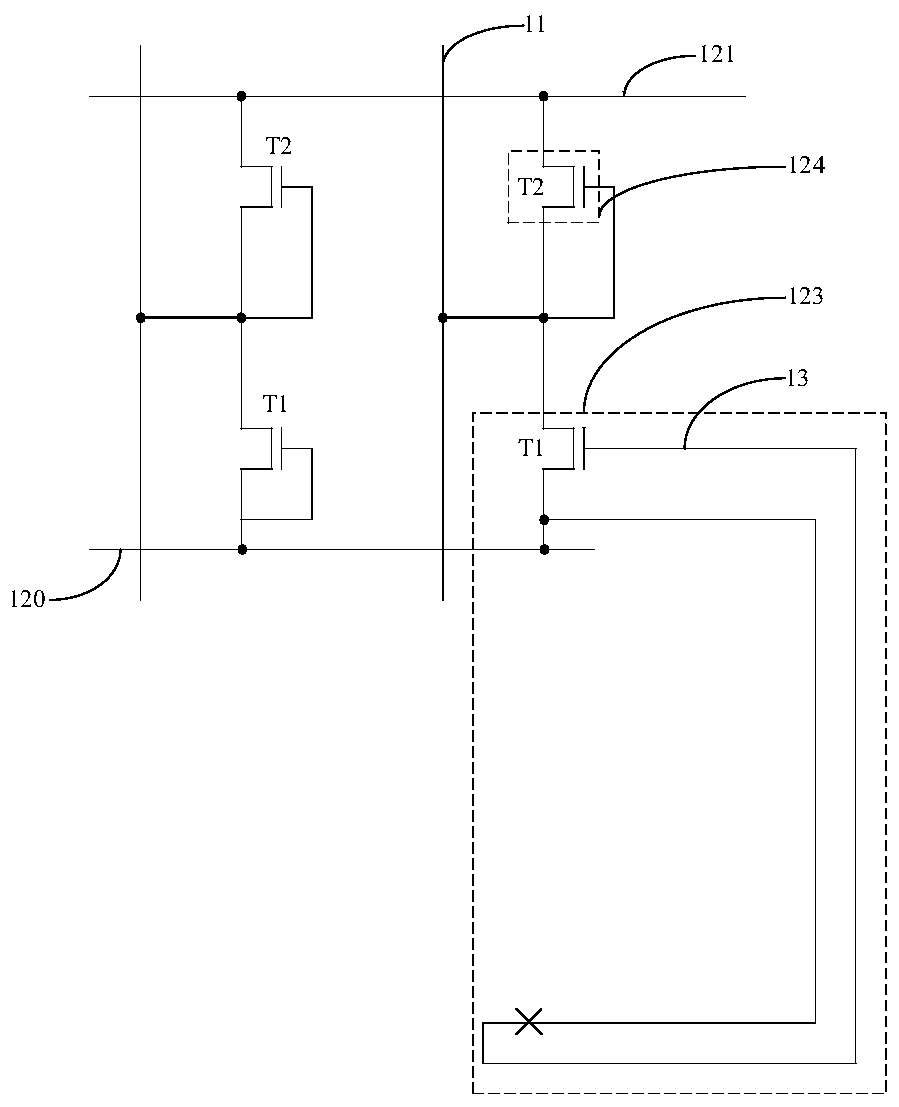

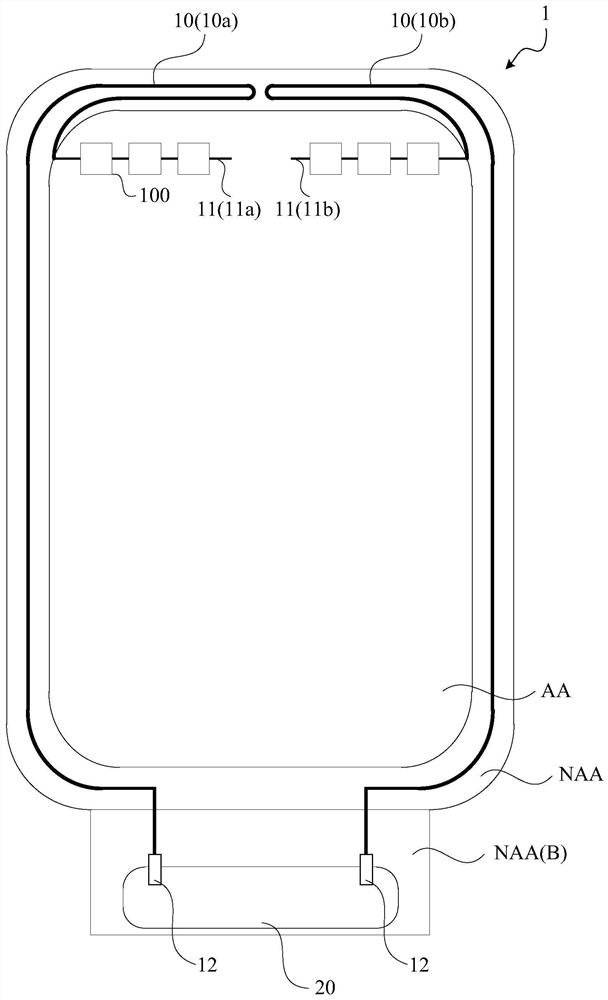

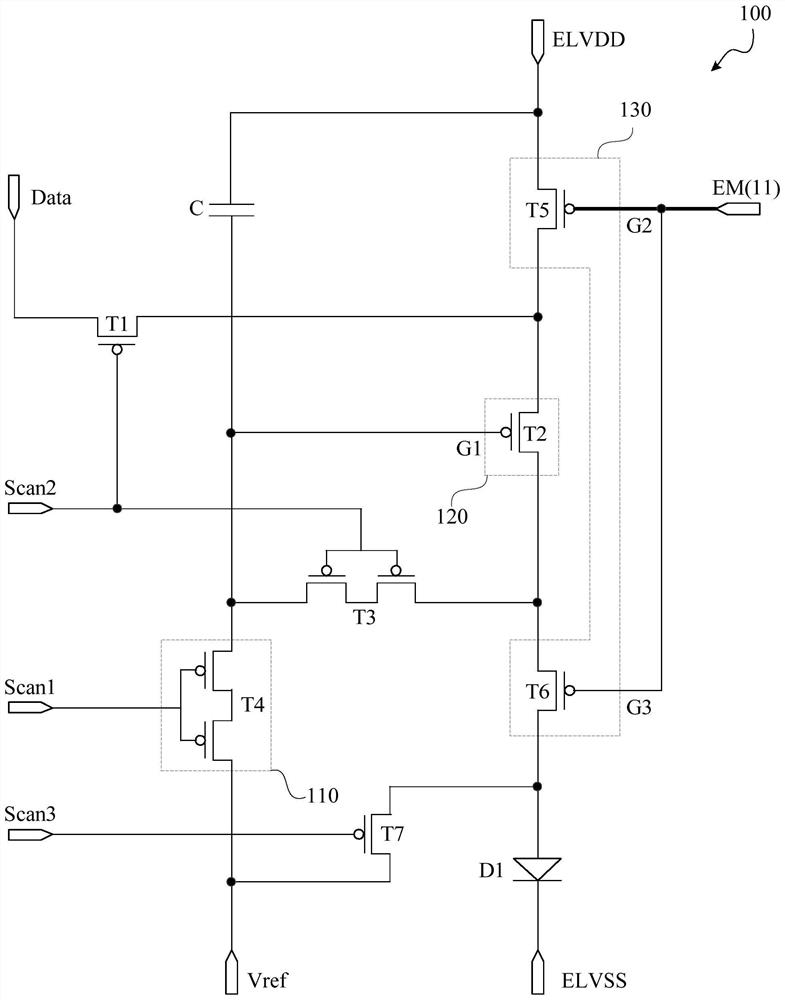

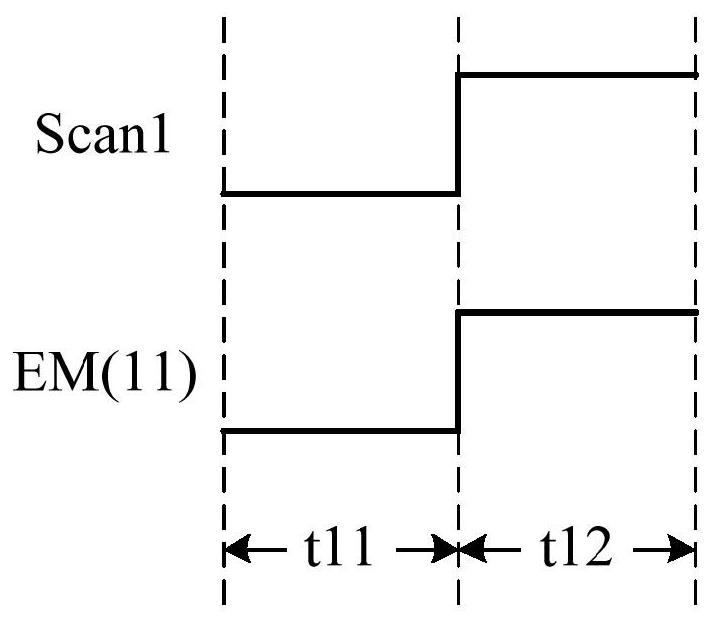

Display panel and crack detection method thereof and display device

PendingCN111833786AImprove the efficiency of failure analysisAvoid problems such as abnormal bright linesStatic indicating devicesComputer hardwareDisplay device

The embodiment of the invention discloses a display panel and a crack detection method thereof and a display device. The display panel is provided with a display area and a non-display area. The display panel includes a dummy pixel circuit and a light emitting device connected to the dummy pixel circuit; the crack detection line is located in the non-display area, one end of the crack detection line is connected with the test terminal, the other end of the crack detection line is connected with the driving signal line, the driving signal line is connected with the dummy pixel circuit, and signals transmitted to the driving signal line by the crack detection line can control the dummy pixel circuit to drive the light emitting device to emit light. According to the technical scheme providedby the embodiment of the invention,the crack detection lines, the corresponding driving signal lines and the dummy pixel circuit are connected through the test terminals, and the test signal is transmitted to the light-emitting device connected with the dummy pixel circuit, thereby achieving the crack detection of the display panel, facilitating the implementation of a narrow-frame design, reducing the abnormality risk of a detection image, and improving the failure analysis efficiency of the display panel and the detection efficiency of a defective product.

Owner:YUNGU GUAN TECH CO LTD

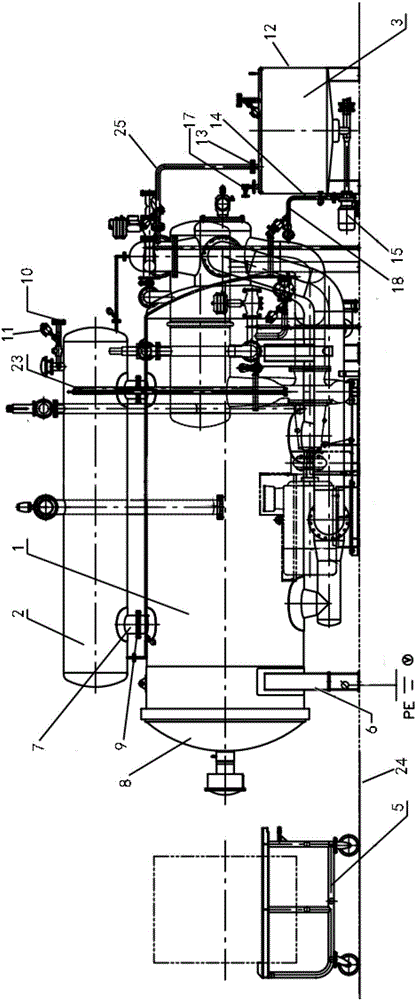

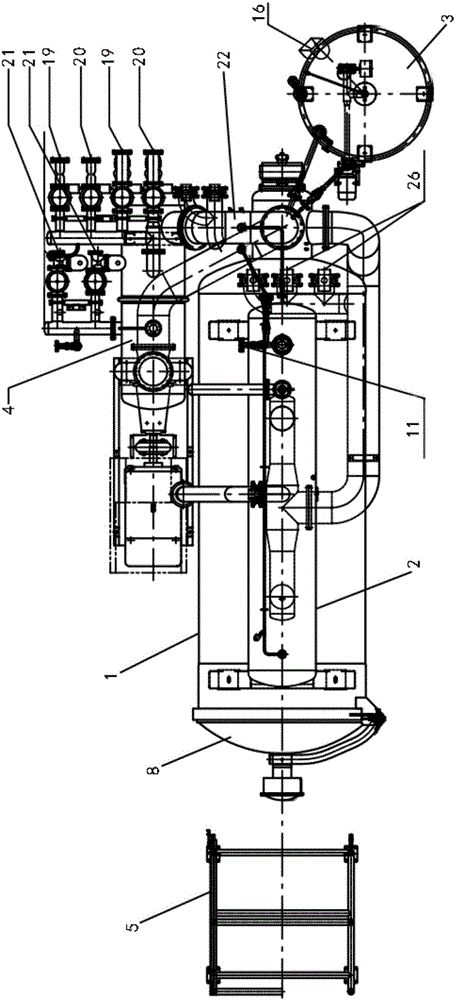

Horizontal kiering tank for kiering gauze

ActiveCN106381621AImprove bleaching efficiencyImprove pass rateTextile treatment containersTextile treatment machine arrangementsEngineeringWater level

The invention discloses a horizontal kiering tank for kiering gauze. The horizontal kiering tank comprises a main cylinder body, an expanding cylinder, a preparation cylinder, a heat exchanger, a control panel and a water gauge device, wherein the main cylinder body is cylindrical, is horizontally arranged on a cylinder body bracket, is used for accommodating fabrics and rinsing solution, and is a place for carrying out a rinsing process; the expanding cylinder is arranged above the main cylinder body, and is used for reducing the pressure inside the main cylinder body; the preparation cylinder comprises a barrel, a water inlet, a water outlet, a stirring motor, a charging pump motor and a pressurizing opening, and is used for preparing a bleaching agent; the heat exchanger is used for heating tap water and introducing the tap water into the preparation cylinder; the control panel is used for setting programs and controlling operation of the kiering tank; and the water gauge device is used for monitoring the water level in the main cylinder body. According to the horizontal kiering tank, the kiering process and bleaching agent preparation are mechanized, the gauze bleaching efficiency is improved, and only one person is required for operation, so that the production time and labor cost can be reduced; and the main cylinder body is horizontally arranged, so that the height of a workshop can be reduced, and an operation platform is not required.

Owner:MEDWELL MEDICAL PROD

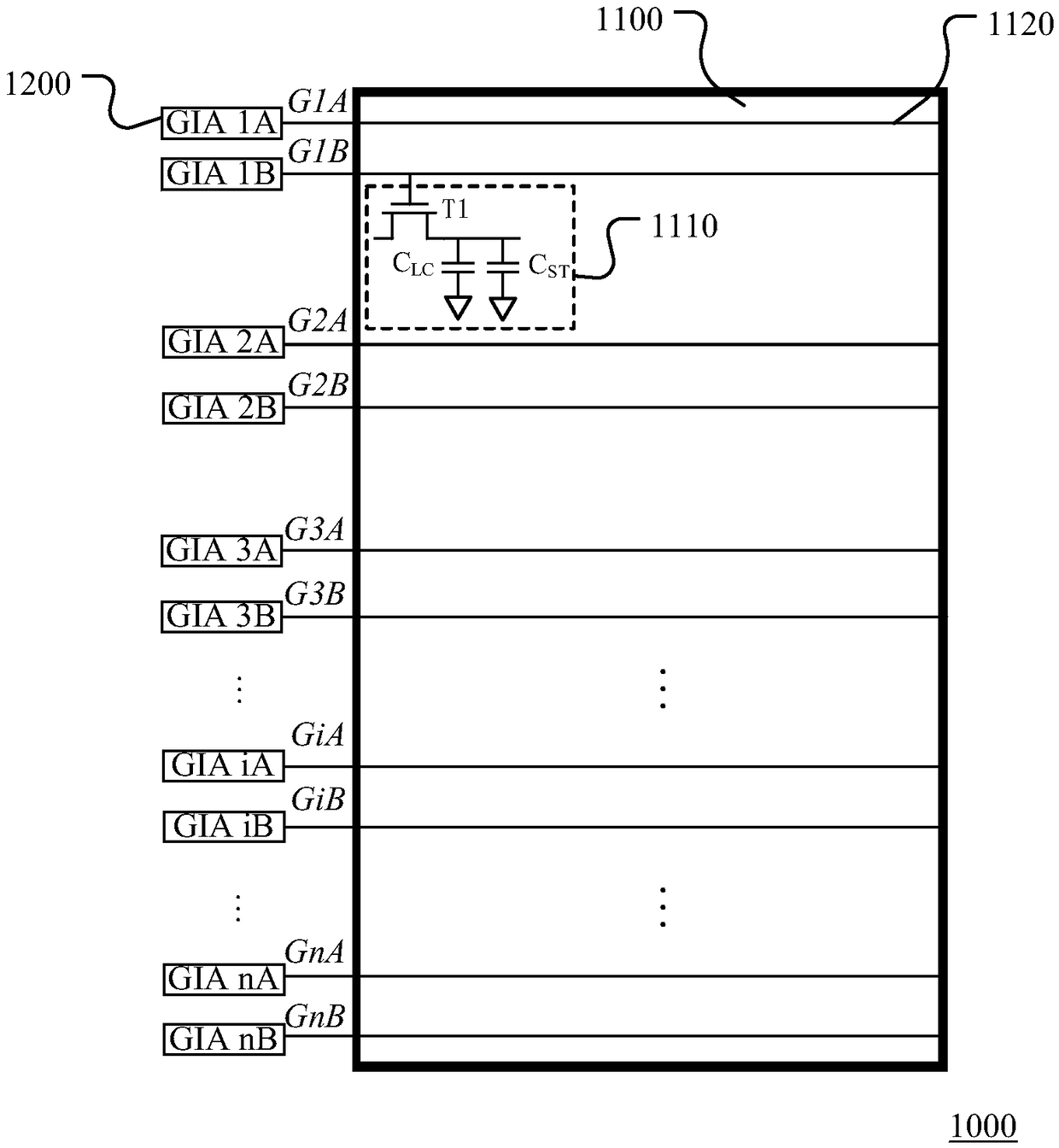

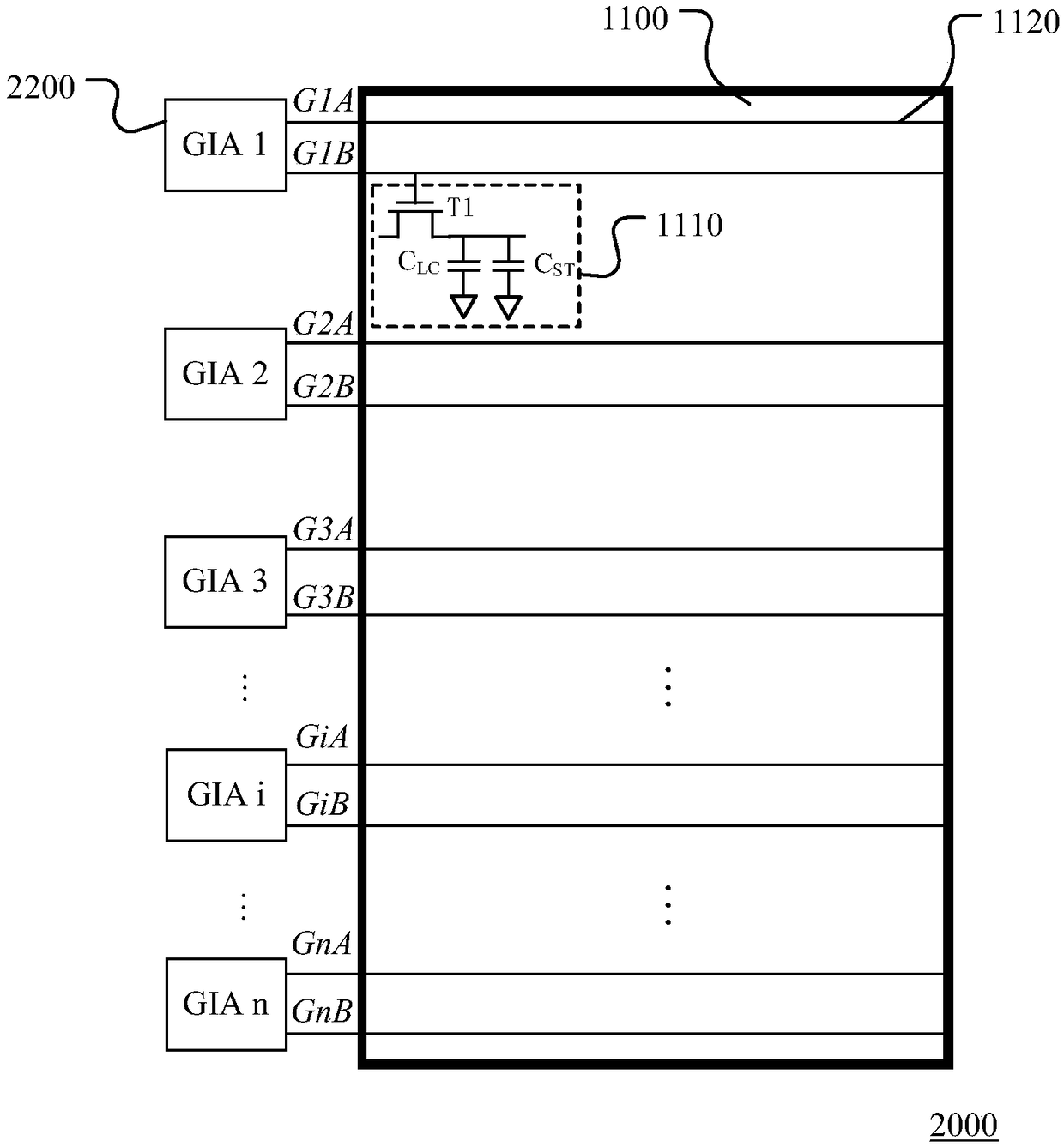

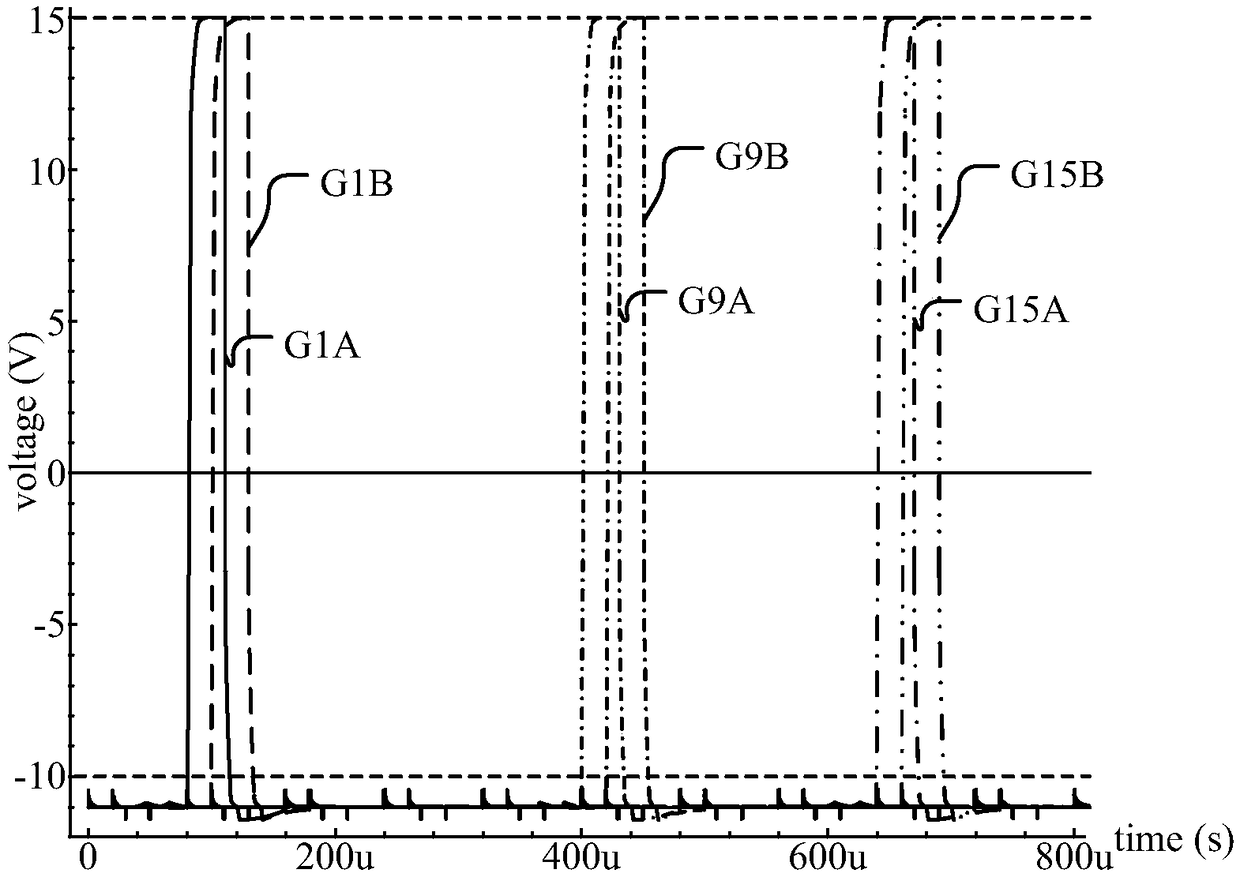

Gate driving circuit and display device thereof

ActiveCN109461401AImprove stabilityReduce the difficulty of integrationStatic indicating devicesDisplay deviceEngineering

The invention discloses a gate driving circuit and a display device thereof. The gate driving circuit comprises multi-stage gate driving units, wherein each gate driving unit comprises an input module, an output module and a drop module, wherein each input module is used for conducting precharging according to a pre-stage driving signal and supplying voltage to first and second nodes; each outputmodule generates a first gate driving signal according to a first clock signal and the voltage of the first nodes and generates a second gate driving signal according to a second clock signal and thevoltage of the second nodes; each drop module generates a first drop signal to drop the voltage of the first nodes according to a third clock signal and generates a second drop signal to drop the voltage of the second nodes according to a subsequent driving signal, and the first gate driving signals and the second gate driving signals sequentially drive two adjacent gate lines on a display panel.According to the gate driving circuit and the display device thereof, on the basis of high resolution, the number of the gate driving units is reduced by half, so that the probability that the displaydevice may be attacked by an adverse risk is reduced, and the narrow-frame design of the display device with high resolution is facilitated.

Owner:KUSN INFOVISION OPTOELECTRONICS

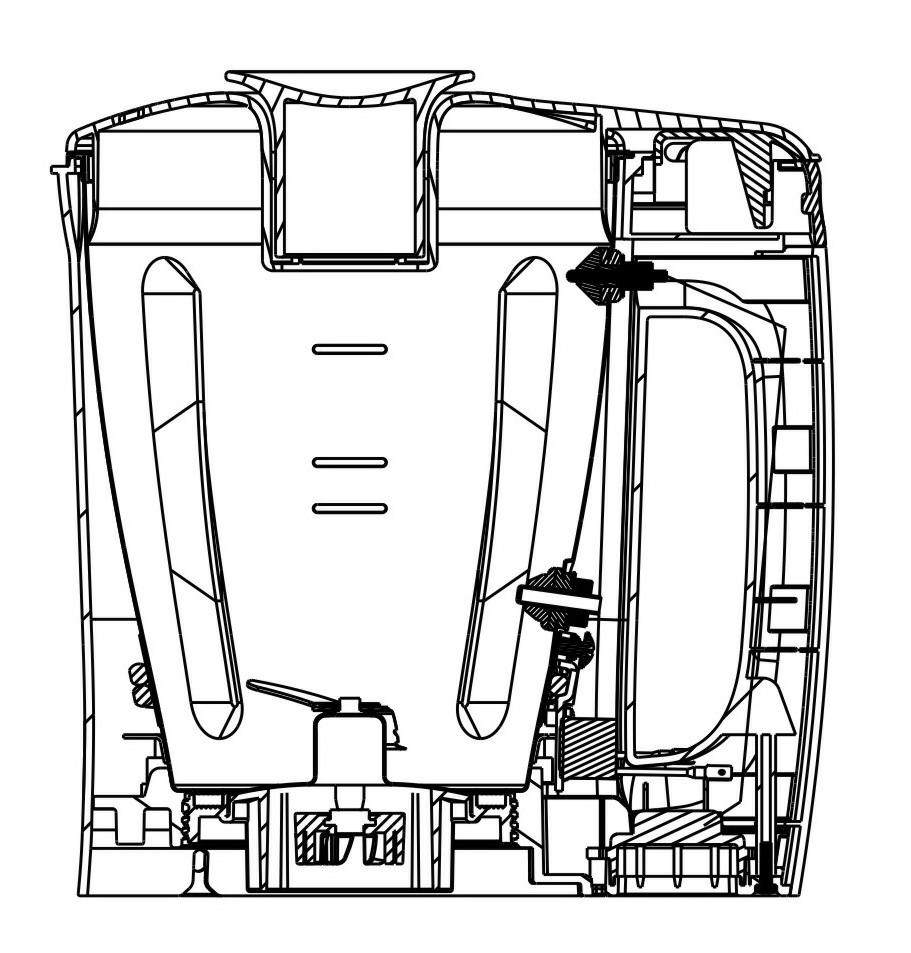

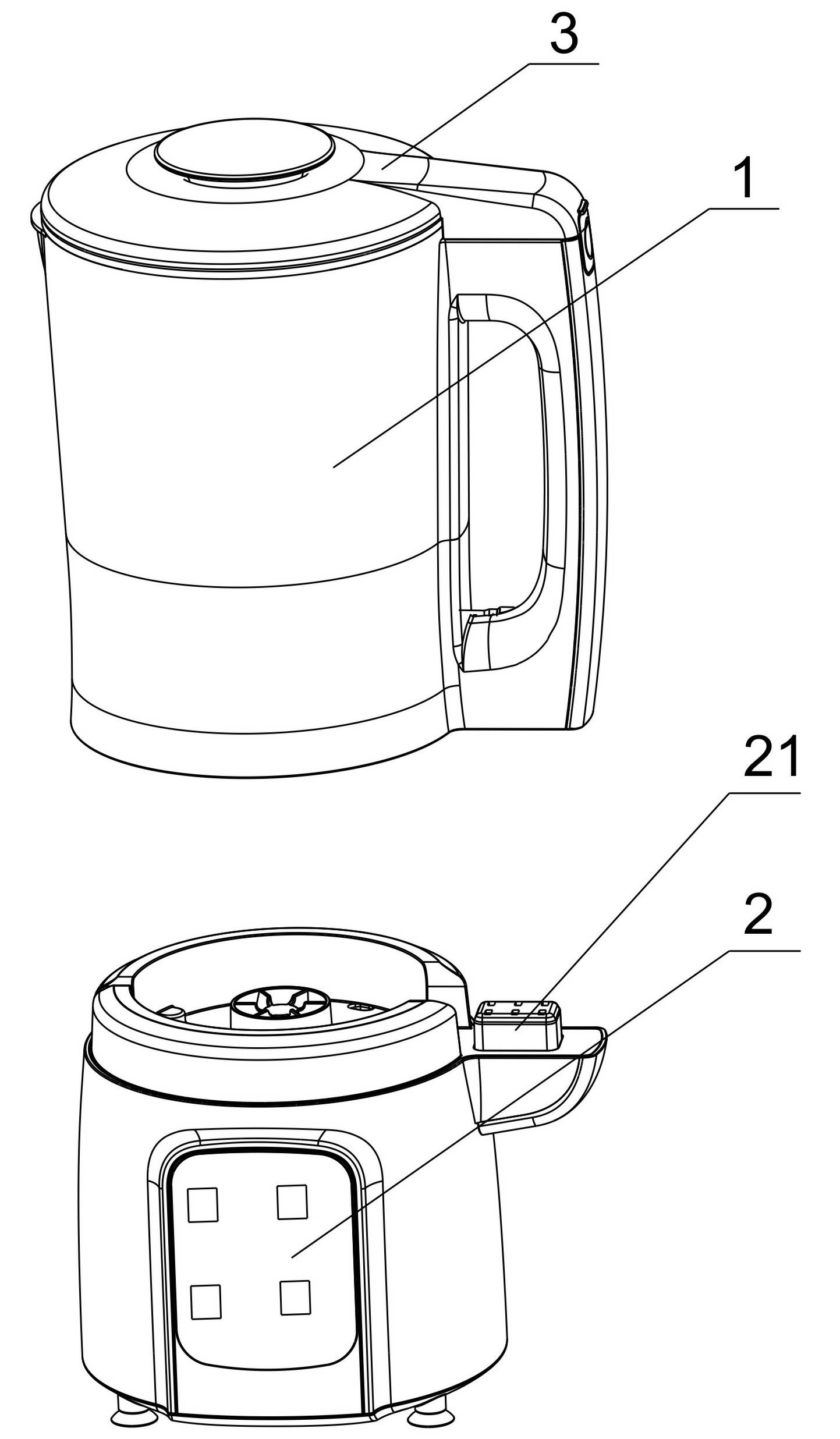

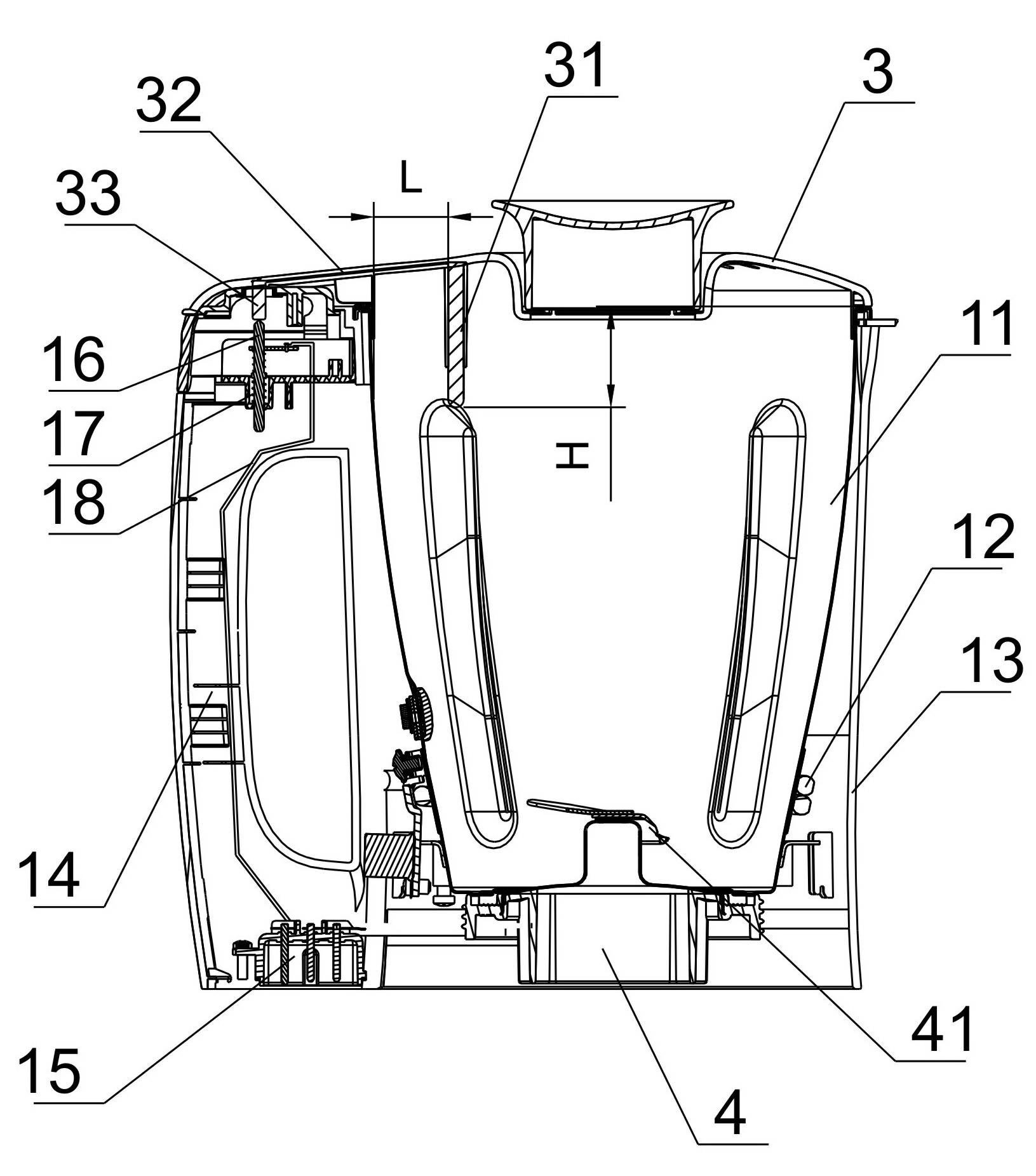

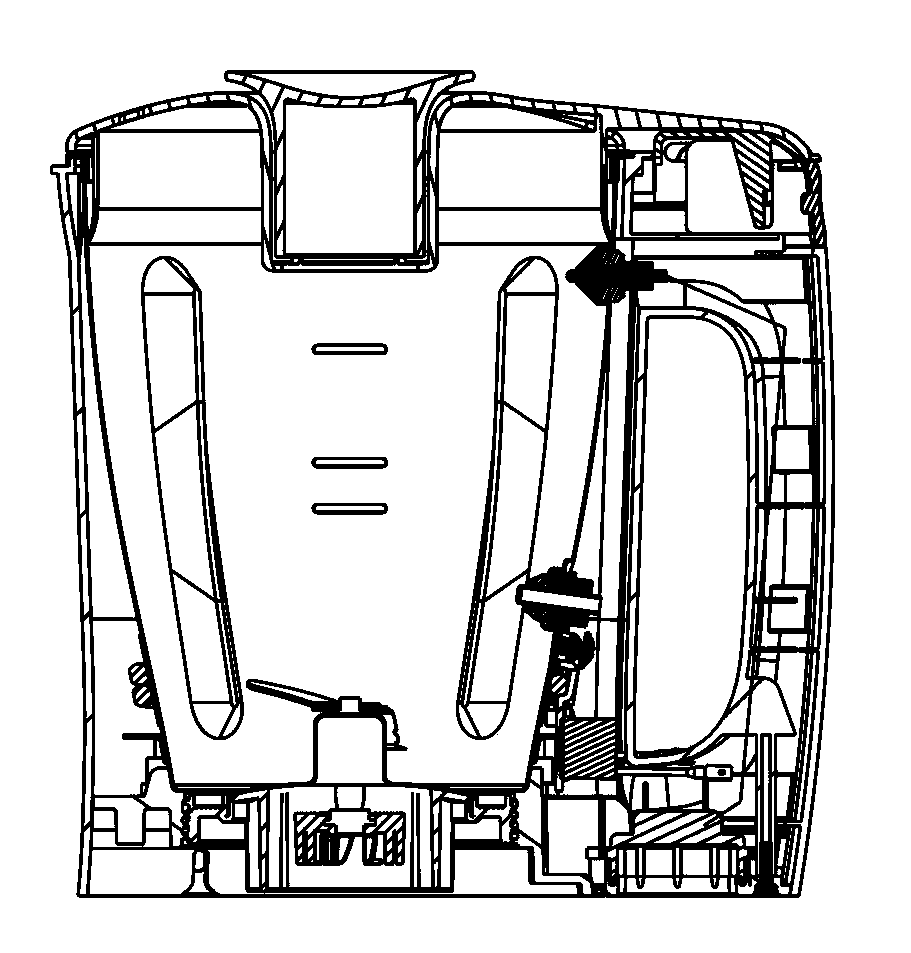

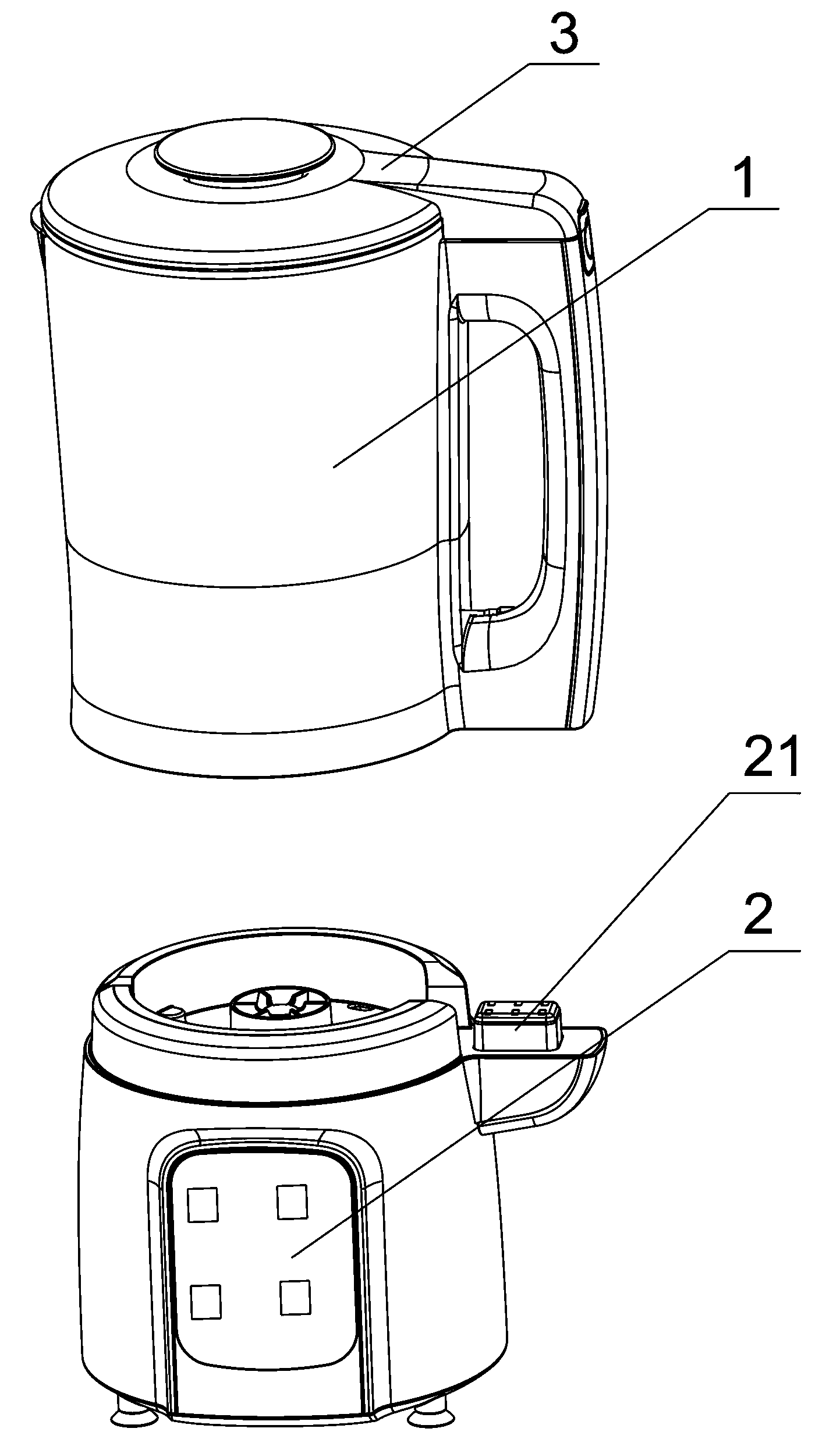

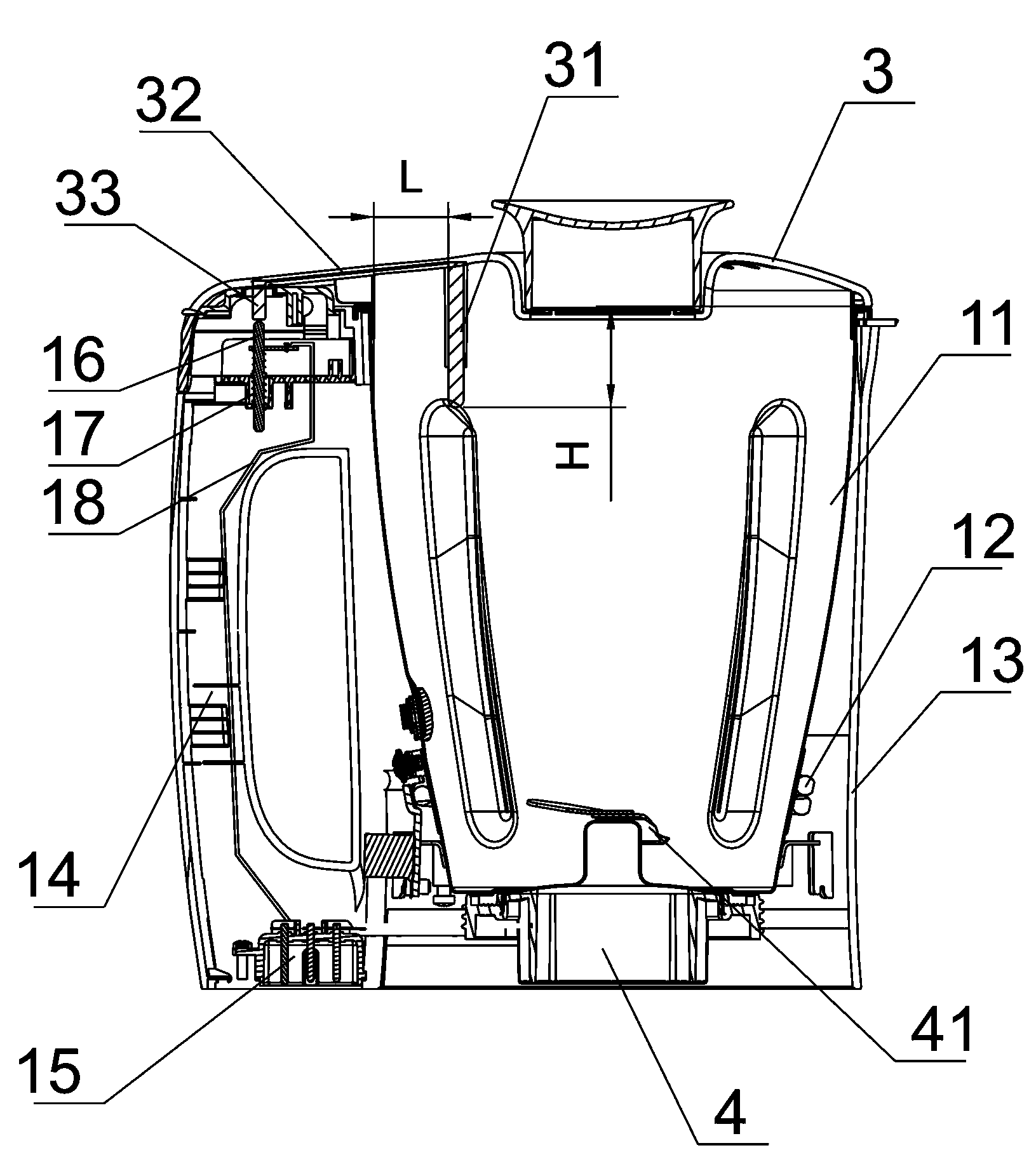

Anti-overflow food processing machine

The invention discloses an anti-overflow food processing machine, comprising a machine bed, a motor and a control unit arranged in the machine bed, and a blending cup arranged on the machine bed; the blending cup comprises a cup body, a heating body and a shell; the blending cup is further provided with an upper cover and a cutter holder; and the cutter holder is provided with a blending cutter. The anti-overflow food processing machine is characterized in that the upper cover is provided with an anti-overflow device, the anti-overflow device comprises an anti-overflow probe, wherein one end of the anti-overflow probe is inserted into the cup body and the other end of the anti-overflow probe is embedded into the upper cover and in electric or signal connection with the control unit. The anti-overflow device is arranged on the upper cover, therefore, signal fault due to that the food is adhered onto the anti-overflow probe in the processing procedure of the food processing machine can be effectively solved, and the blending cup is easy to clean; and the anti-overflow device is integrally manufactured with the upper cover so that easiness in manufacture is achieved.

Owner:JOYOUNG CO LTD

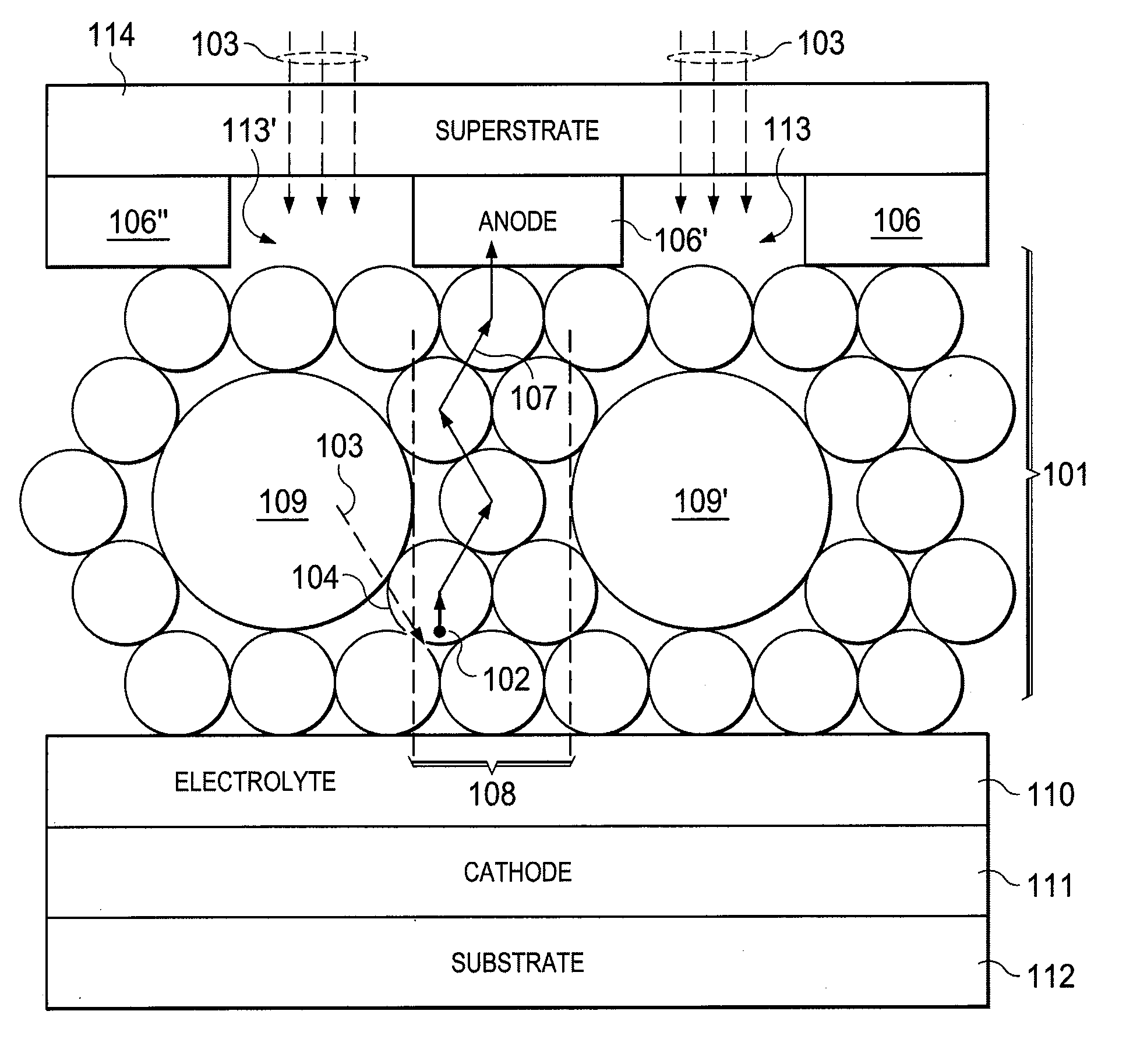

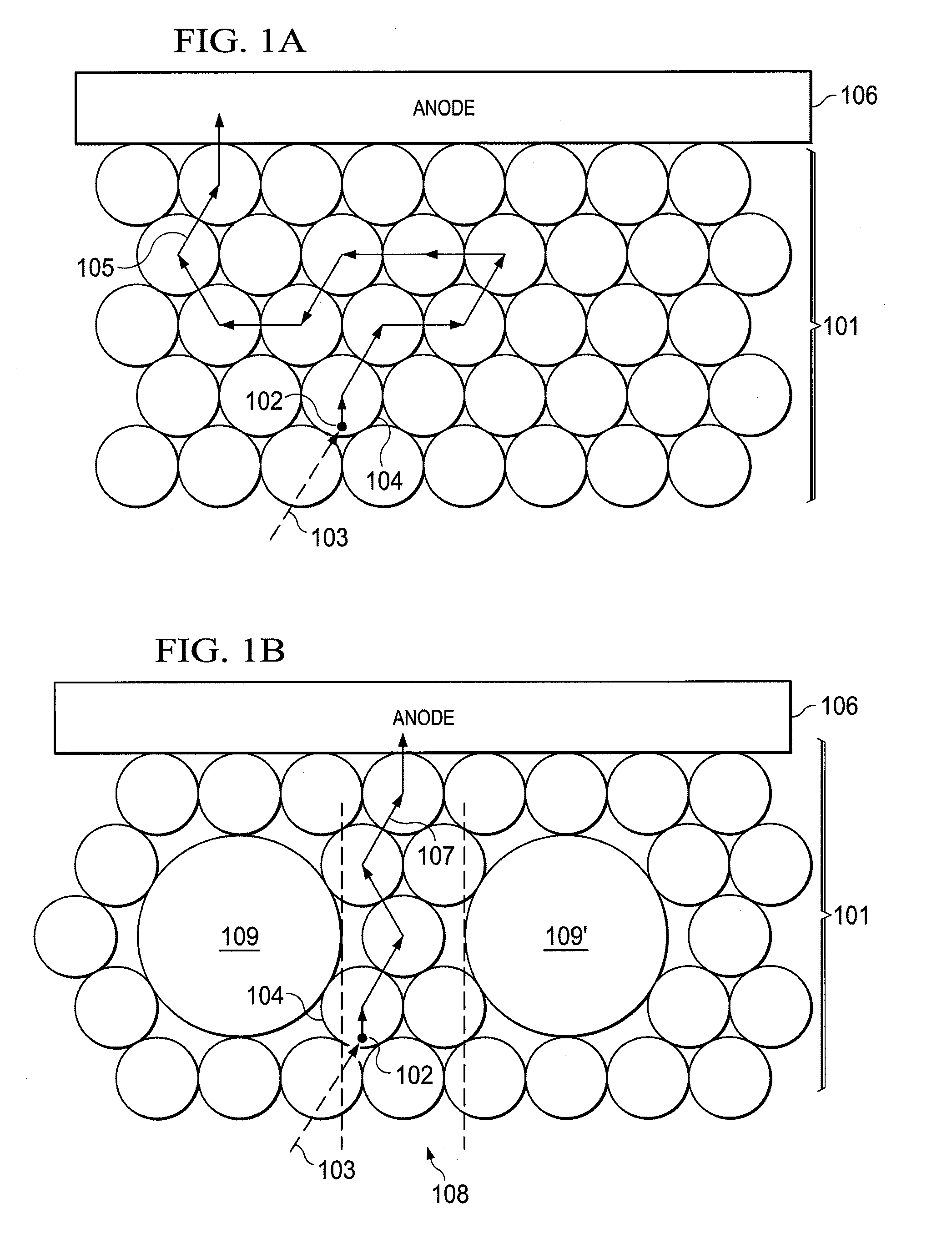

Additives for solar cell semiconductors

InactiveUS20110226306A1Improve conversion efficiencyHigh electron mobilityElectrolytic capacitorsPV power plantsSolar cellSilicon dioxide

A dye-sensitized solar cell (“DSSC”) includes an anode, a cathode, a semiconductor layer, a dye covalently attached to the semiconductor layer, and an electrolyte, wherein the semiconductor layer includes a metal oxide and an organic or inorganic insulating component to facilitate forward transfer of electrons to the anode. The semiconductor additive or insulating component may include, for example, alpha aluminum oxide, gamma aluminum oxide, fumed silica, silica, diatomaceous earth, aluminum titanate, hydroxyapatite, calcium phosphate, iron titanate, and mixtures thereof.

Owner:WARNER BABCOCK INST FOR GREEN CHEM

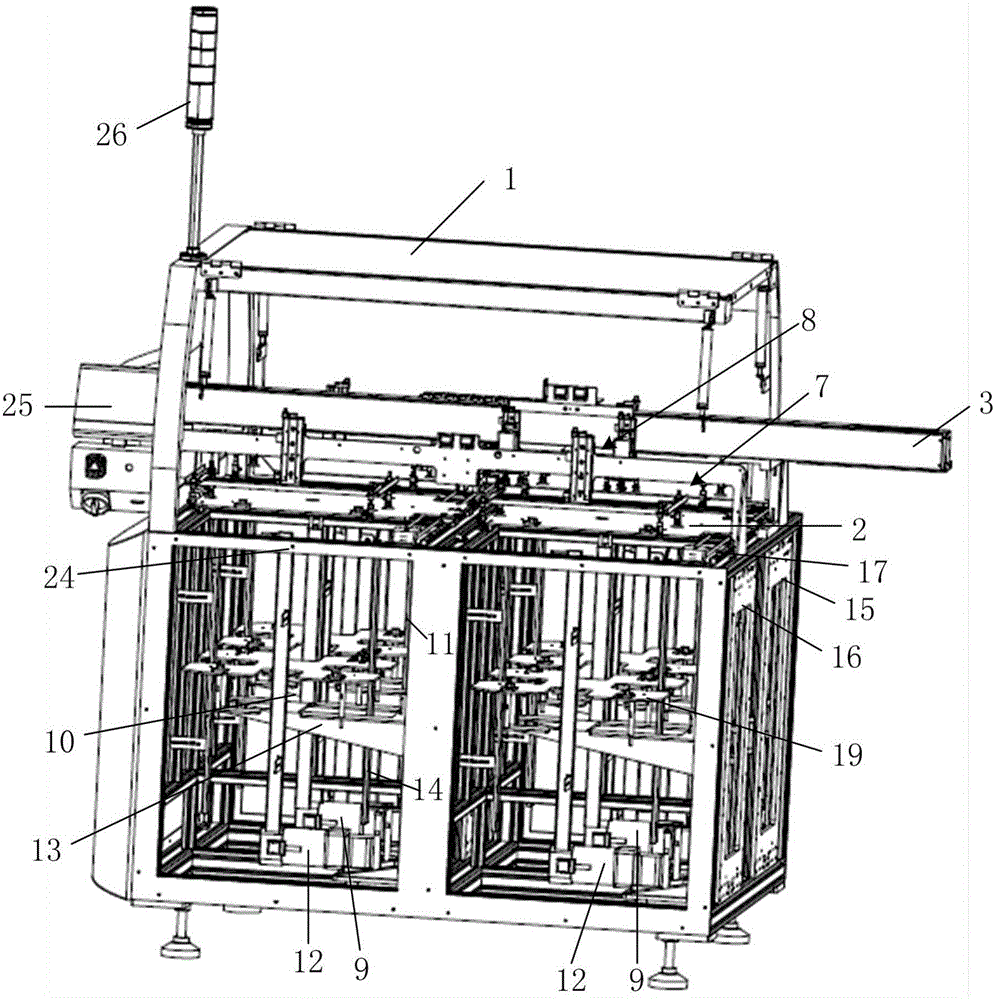

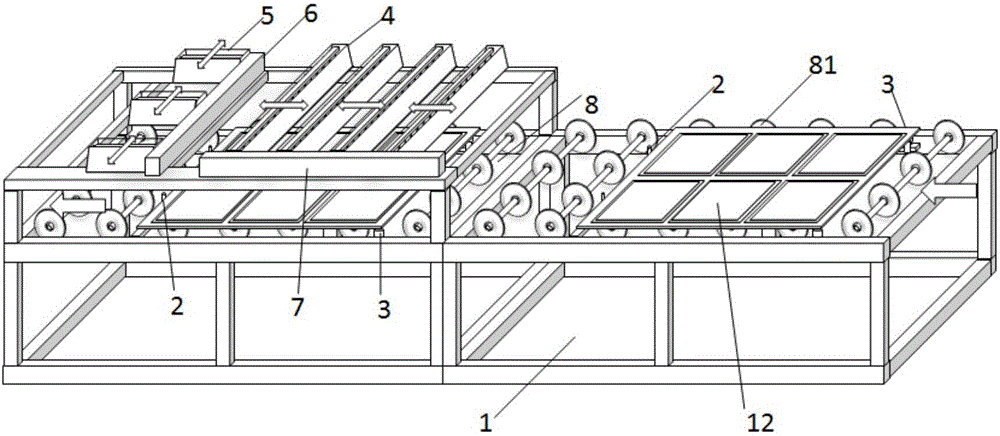

Double-body loading and unloading machine for manufacturing of LCD (liquid crystal display) products

InactiveCN105692194AReduce product defect rateReduce adverse risksConveyorsConveyor partsLiquid-crystal displayProduction line

Owner:SUZHOU PROTECH PRECISION IND CO LTD

Production technology of automotive headliner capable of being provided with invisible microphone

InactiveCN110091560AThe production process steps are simpleEasy to operateSynthetic resin layered productsLaminationCompression moldingEngineering

The invention provides a production technology of an automotive headliner capable of being provided with an invisible microphone, and belongs to the technical field of production of automotive interior parts. The technology comprises the following steps: raw materials of all components of the automotive headliner are placed in a hot die cutting mold, and undergo compression molding to obtain a semi-finished automotive headliner substrate after the molding is finished; the invisible microphone hole site of the semi-finished automotive headliner substrate undergoes water knife cutting treatmentto obtain a finished automotive headliner substrate after the water knife cutting process is finished; a fabric is placed in a laminating mold, and is laminated to obtain a semi-finished automotive headliner; and the semi-finished automotive headliner is subjected to secondary water knife cutting treatment to obtain the automotive headliner after the water knife cutting treatment is finished. Thetechnology has the advantages of simple steps, convenience in operation, increase of the production efficiency, and ensuring the appearance consistency of the top lining fabric.

Owner:WUXI GISSING AUTO PARTS CO LTD

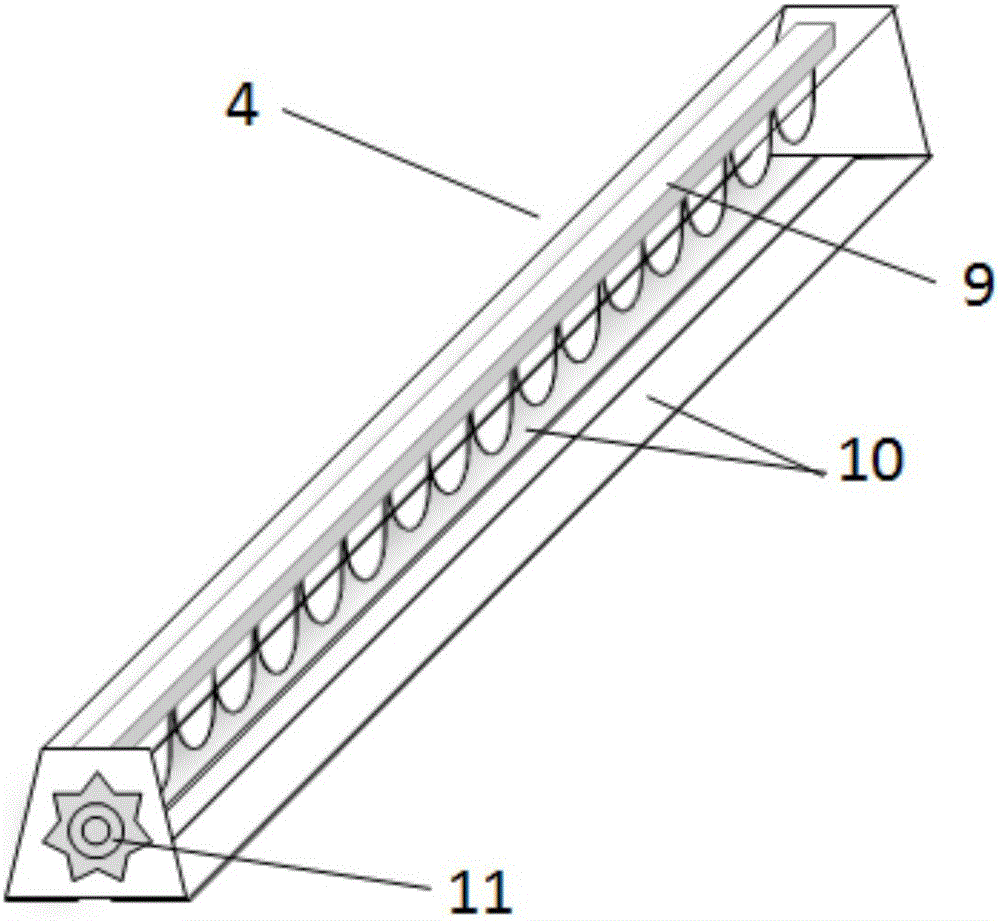

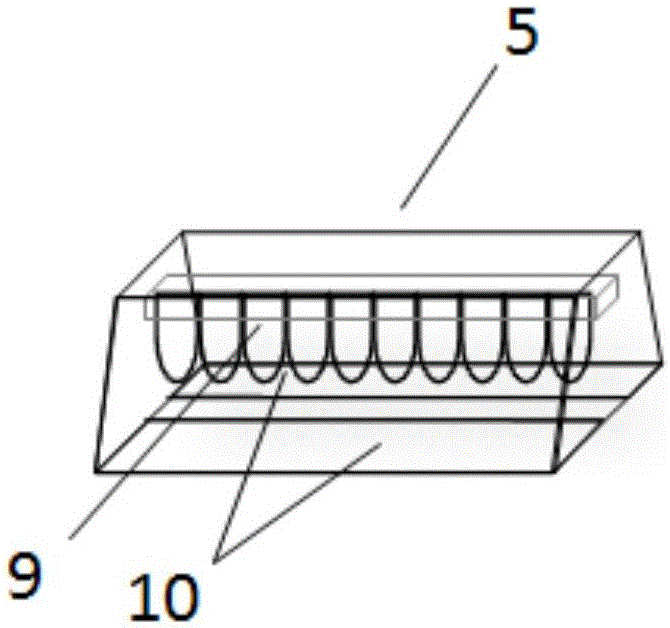

Frame-sealing adhesive curing device and using method

ActiveCN105824154AReduce the risk of badPhotomechanical exposure apparatusMicrolithography exposure apparatusAdhesiveEngineering

The embodiment of the invention discloses a frame-sealing adhesive curing device and a using method. The frame-sealing adhesive curing device comprises a device body, a movable horizontal irradiation portion and a movable vertical irradiation portion, wherein the horizontal irradiation portion and the vertical irradiation portion are arranged on the device body, the horizontal irradiation portion is used for irradiating the horizontal position of a frame-sealing adhesive on a glass substrate, and the vertical irradiation portion is used for irradiating the vertical position of a frame-sealing adhesive on the glass substrate. The frame-sealing adhesive curing device can ensure that a frame-sealing adhesive light source is flexible and movable in position, and the undesirable risk caused by comprehensive irradiation to products is reduced.

Owner:BOE TECH GRP CO LTD +1

Buffer layer and display device

InactiveCN112396960AImprove bonding process yieldEnhanced resistance to physical bendingIdentification meansDisplay deviceComputational physics

The invention discloses a buffer layer and a display device. The buffer layer is used for being attached to a display panel, the buffer layer is provided with a first area and at least one cambered surface area which are complementary, the buffer layer comprises at least one first sub-buffer layer, and the first sub-buffer layer is provided with a plurality of through holes in the cambered surfacearea.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

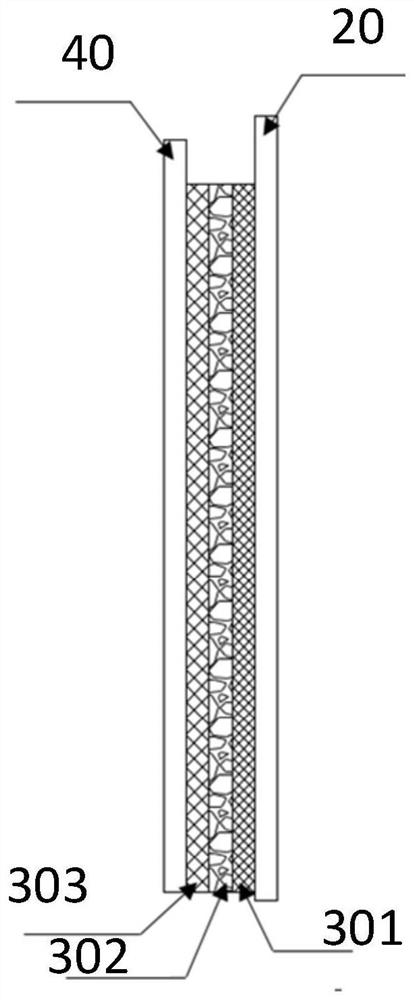

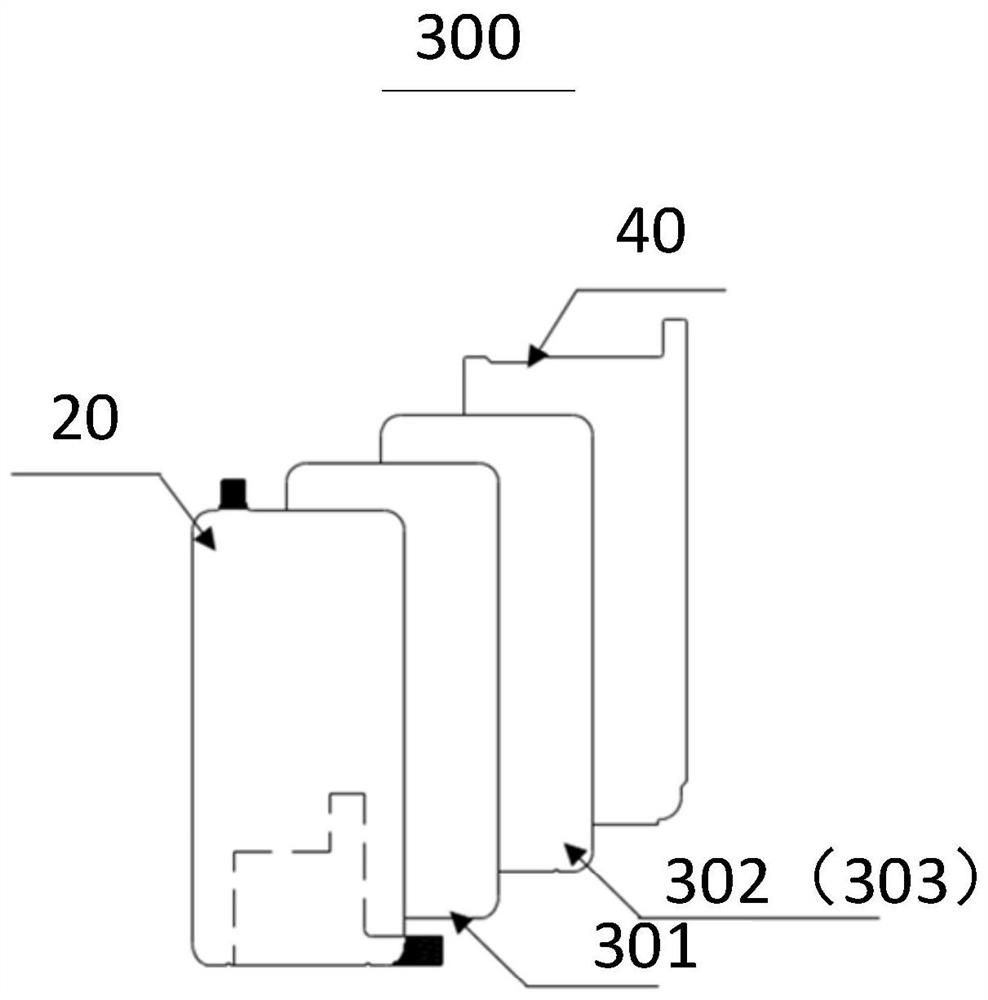

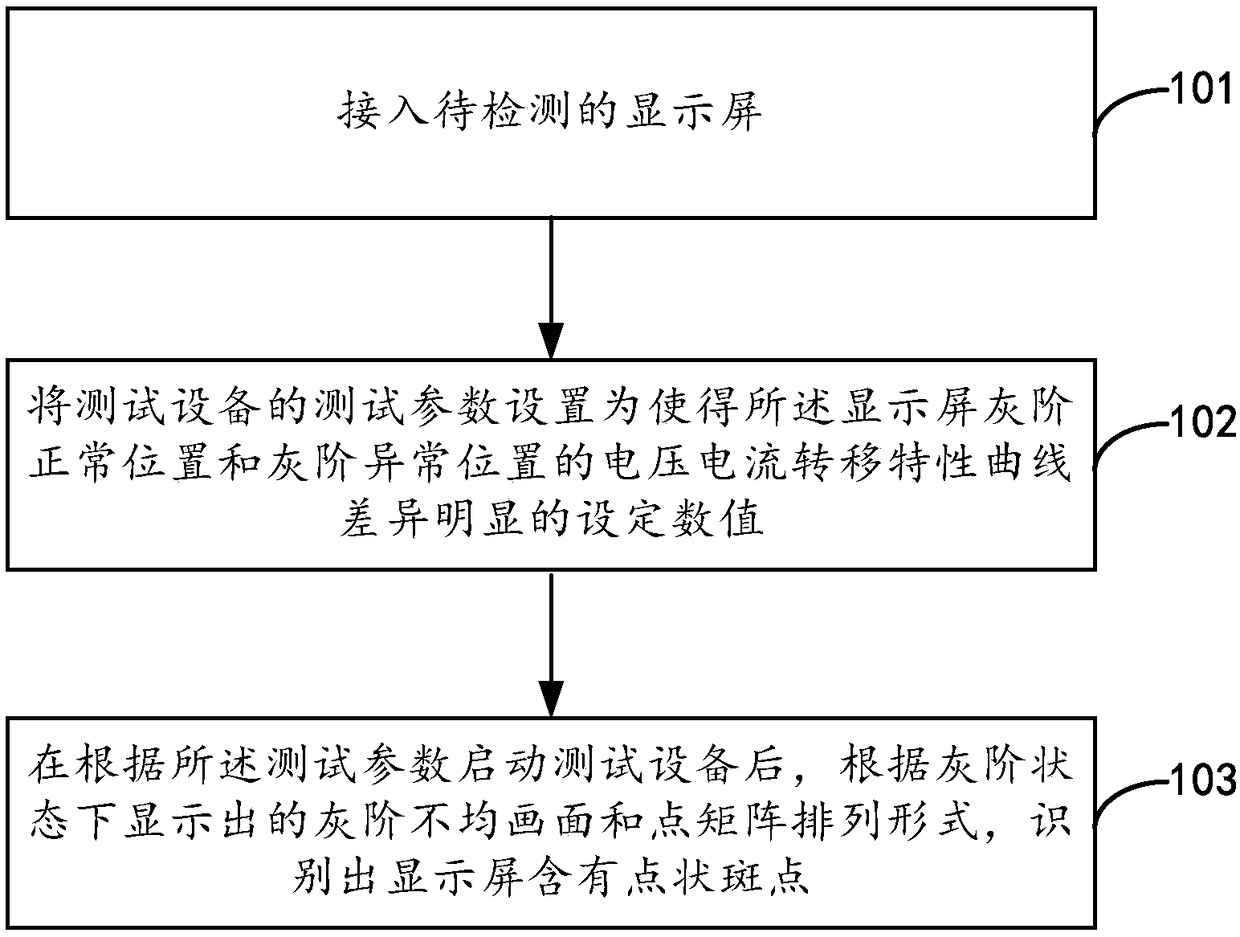

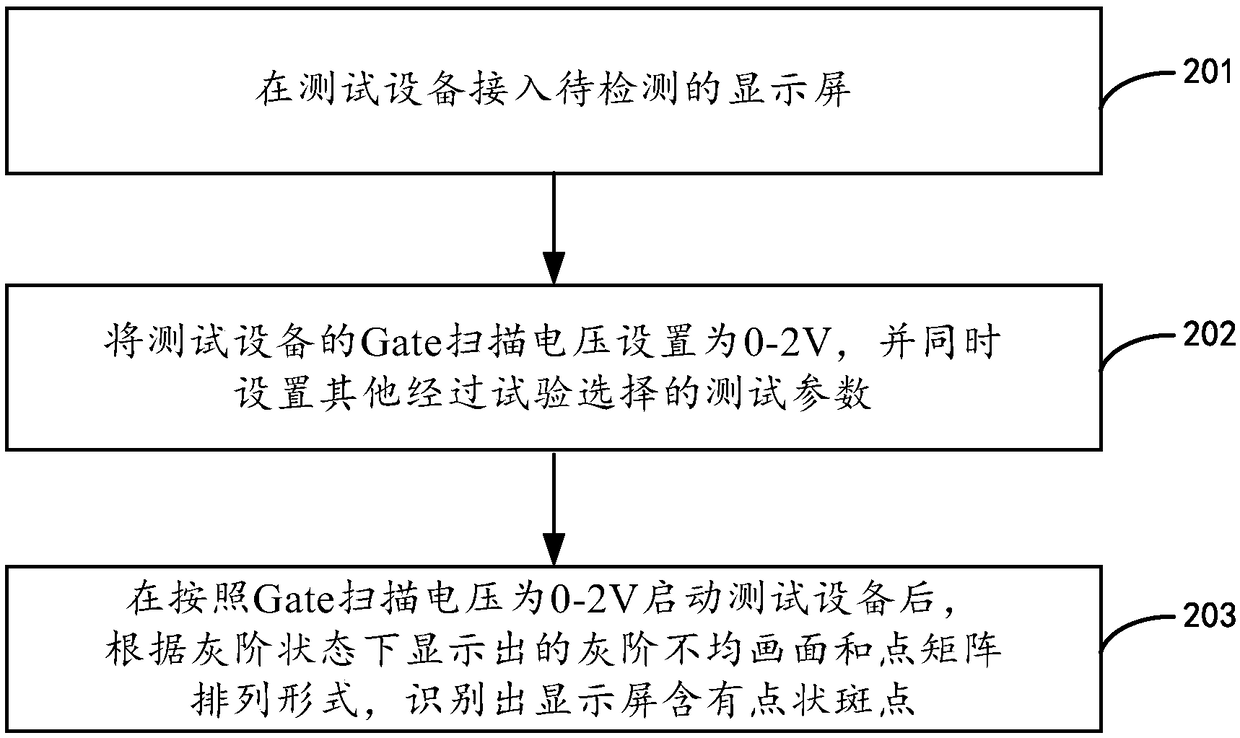

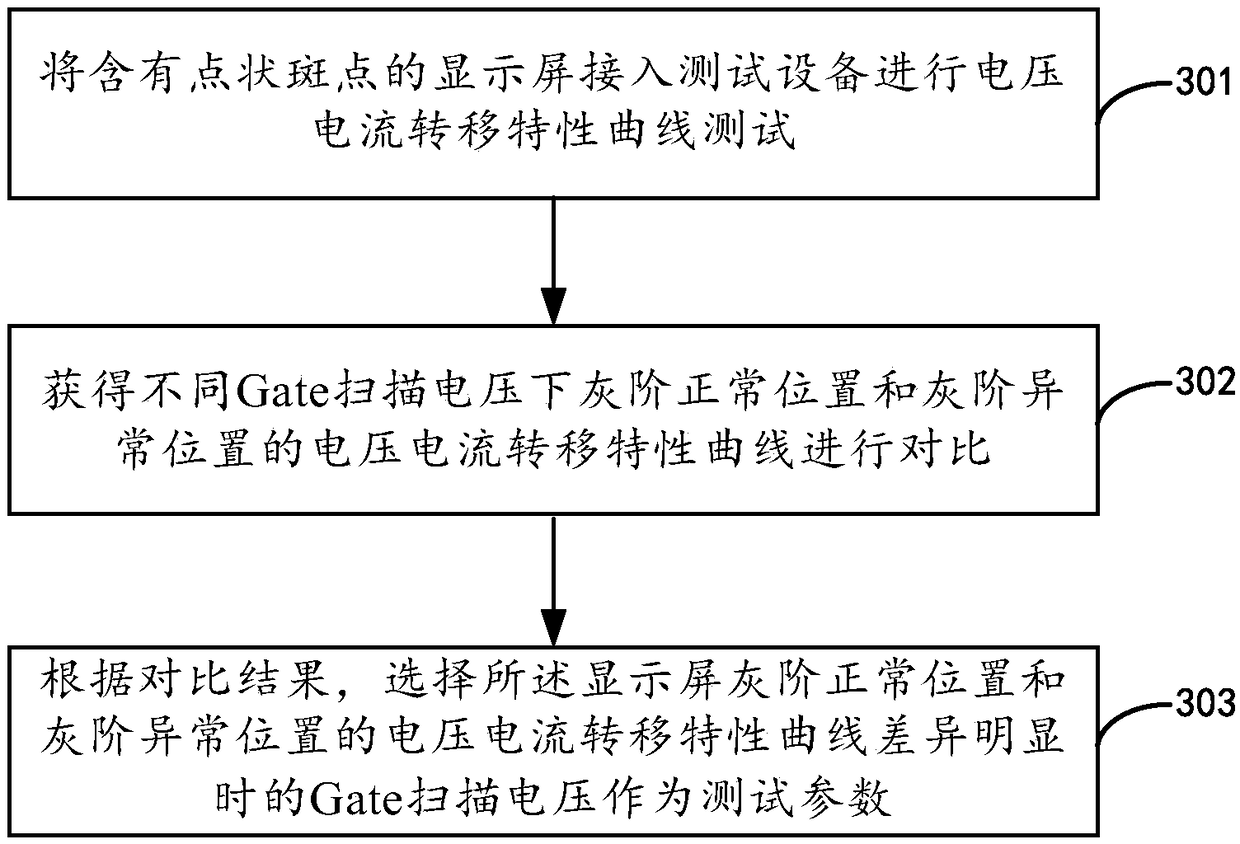

Display screen product detection method and device

ActiveCN108847170AAvoid serious impactReduce the risk of badCurrent/voltage measurementStatic indicating devicesDot matrixPower flow

The invention discloses a display screen product detection method and device. The method comprises steps that a to-be-detected display screen is accessed; a test parameter of a test device is set to be a set value that makes voltage current transfer characteristic curves of the normal gray level position and the abnormal gray level position of the display screen significantly different; after thetest device starts according to the test parameter, according to a gray level uneven frame and a dot matrix arrangement form displayed in the gray level state, that the display screen contains dot spots is identified. The method is advantaged in that a Dot Mura problem of the display screen can be quickly detected under the normal temperature, high-temperature and low-temperature verification costis reduced, and the risk of bad products is reduced.

Owner:TRULY HUIZHOU SMART DISPLAY

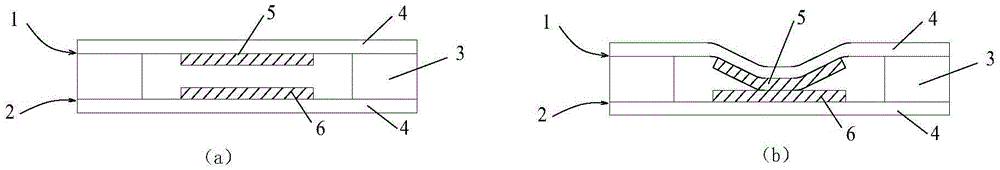

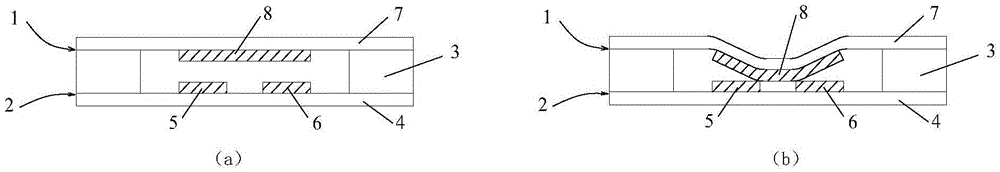

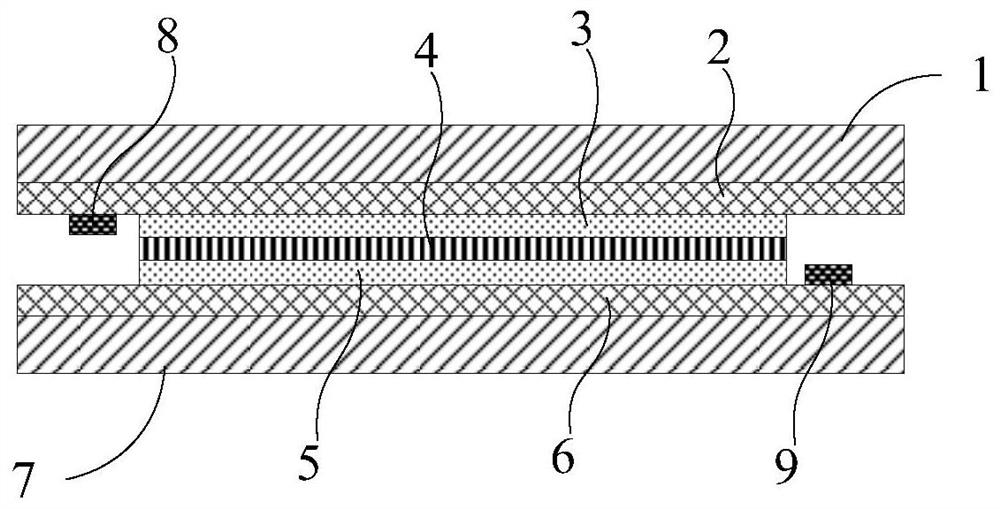

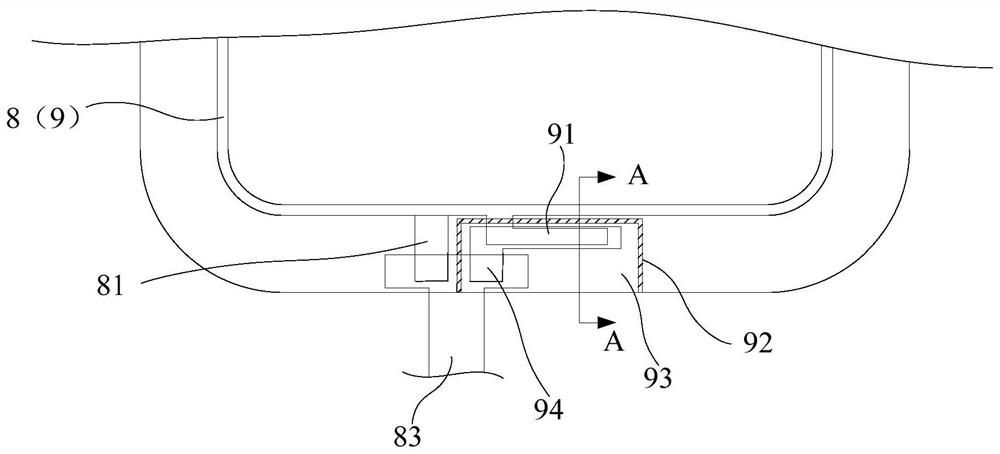

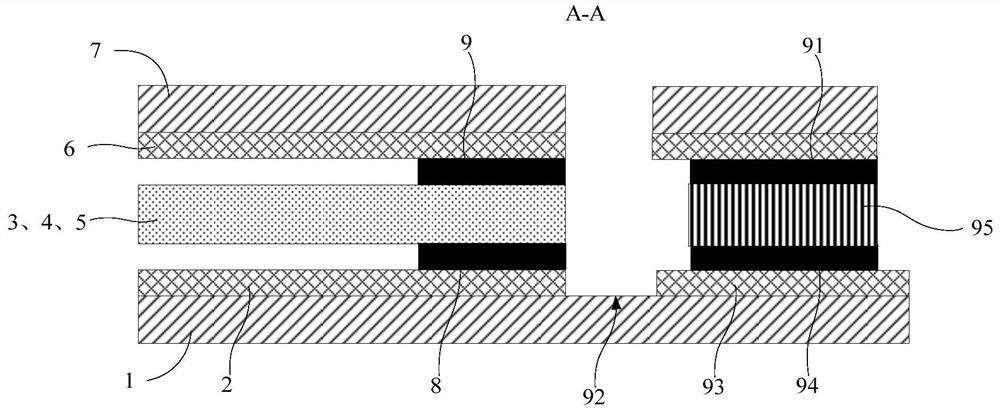

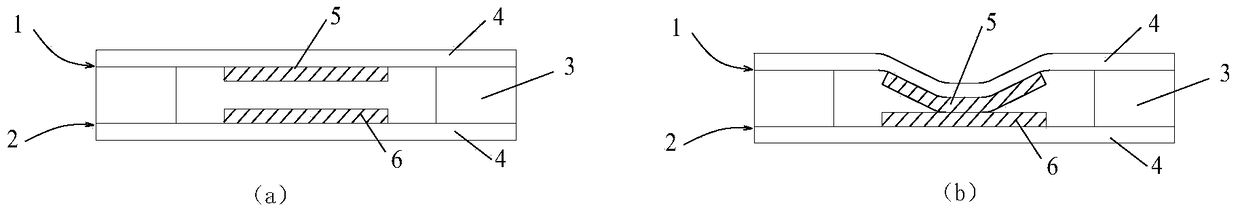

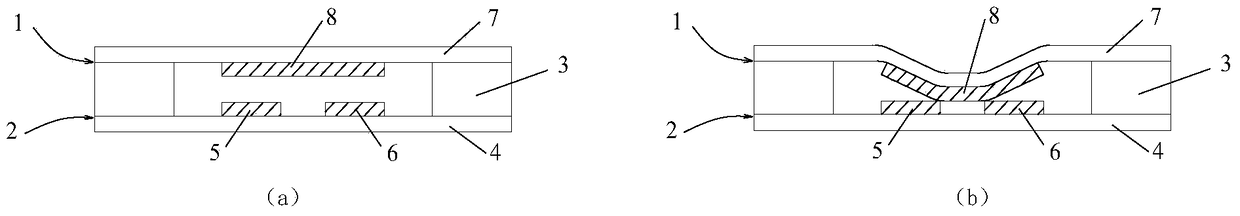

Membrane switch

ActiveCN105655178AReduce the risk of badSimple processContact with seperate bridge contactElectric switchesElectrical conductorMembrane switch

The invention discloses a membrane switch. The membrane switch comprises an upper electric-conduction layer, a lower electric-conduction layer and an insulating layer located between the upper electric-conduction layer and the lower electric-conduction layer, wherein one of the upper electric-conduction layer and the lower electric-conduction layer includes an electric-conduction circuit layer as well as a positive pole triggering part and a negative pole triggering part which are arranged on the electric-conduction circuit layer, and the other electric-conduction layer includes a first base material layer and an electric conductor which is arranged on the first base material layer and is in conduction with the positive pole triggering part and the negative pole triggering part. According to the membrane switch of the invention, the positive pole triggering part and the negative pole triggering part are simultaneously arranged on the upper electric-conduction layer or the lower electric-conduction layer, and the corresponding upper electric-conduction layer or the lower electric-conduction layer is provided with the electric conductor with an electric-conduction function. When the membrane switch is pressed, the electric conductor simultaneously contacts with the positive pole triggering part and the negative pole triggering part, a positive pole and a negative pole are conducted, and the switch is switched on. According to the membrane of the invention, only one electric-conduction circuit layer is needed to be arranged on the layer which is provided with the positive pole triggering part and the negative pole triggering part, and therefore, compared with a traditional membrane switch, the membrane switch of the invention has the advantages of simple process and high production efficiency; and just a single circuit layer is adopted, so that production cost can be greatly reduced.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

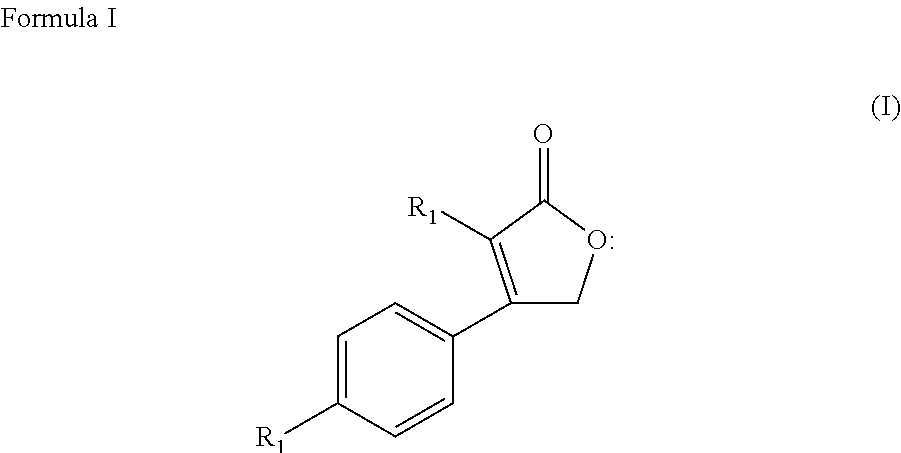

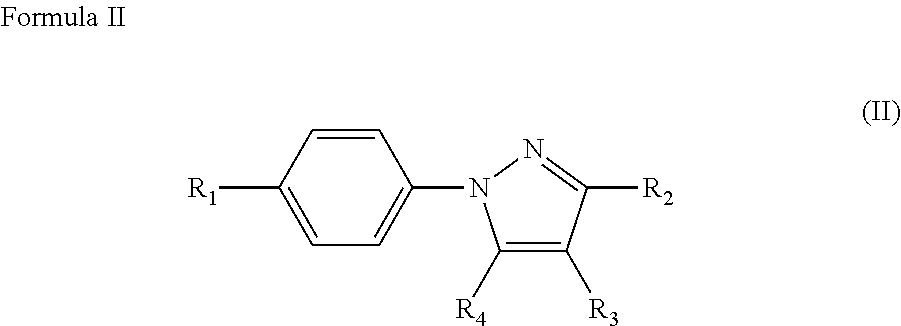

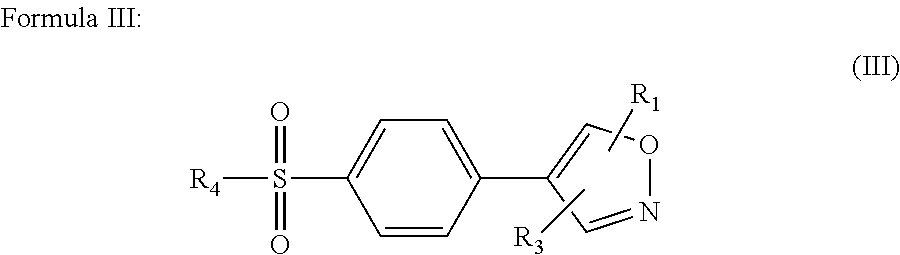

Prophylactic treatment of migraine

ActiveUS8680081B2Reduce the risk of badOvercome problemsBiocideSalicyclic acid active ingredientsSalicylic acidCyclooxygenase

The present invention provides methods and compositions for the prophylactic or targeted prophylactic treatment of migraine. In one embodiment a patient is regularly given a therapeutically effective amount of a combination of a cyclooxygenase-2 inhibitor and acetylsalicylic acid or active derivative, for prophylactic treatment of migraine. In another embodiment, a patient, at a time prior to a determined time window, is administered a therapeutically effective amount of a cyclooxygenase-2 inhibitor, either alone or in combination with acetylsalicylic acid or active derivative, to prevent or reduce migraine symptoms during the time window. Representative compositions include a cyclooxygenase-2 inhibitor and acetylsalicylic acid or salicylate salt.

Owner:CELSPRIN

Electronic equipment, shell assembly and color-changing diaphragm

PendingCN113406834AReduce thicknessSmall structureStatic indicating devicesTelephone set constructionsEngineeringElectrochromism

The invention provides electronic equipment, a shell assembly and a color-changing diaphragm. A first conductive layer and a second conductive layer of the color-changing diaphragm are arranged on the same surface of a first substrate at intervals; the electrochromic layer is arranged on the first conductive layer. An ion storage layer is arranged on the second conductive layer; the electrolyte layer covers the electrochromic layer and the ion storage layer at the same time; the second substrate covers the electrolyte layer; the third conductive layer is arranged on one side, deviating from the electrolyte layer, of the second substrate. A liquid crystal layer is arranged on the third conductive layer; a fourth conductive layer is arranged on the liquid crystal layer; the third substrate is arranged on the side, away from the liquid crystal layer, of the fourth conductive layer. According to the color-changing diaphragm, a liquid crystal structure and an electrochromic device are combined, and the combined color-changing diaphragm can present transparent, non-transparent and multi-color-changing transmission effects; besides, the electrochromic layer and the ion storage layer of the electrochromic structure are arranged on the same layer, so that the structure of a conduction region can be omitted, the adverse risk caused by processing is reduced, and the yield of products is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Anti-overflow food processing machine

The invention discloses an anti-overflow food processing machine, comprising a machine bed, a motor and a control unit arranged in the machine bed, and a blending cup arranged on the machine bed; the blending cup comprises a cup body, a heating body and a shell; the blending cup is further provided with an upper cover and a cutter holder; and the cutter holder is provided with a blending cutter. The anti-overflow food processing machine is characterized in that the upper cover is provided with an anti-overflow device, the anti-overflow device comprises an anti-overflow probe, wherein one end of the anti-overflow probe is inserted into the cup body and the other end of the anti-overflow probe is embedded into the upper cover and in electric or signal connection with the control unit. The anti-overflow device is arranged on the upper cover, therefore, signal fault due to that the food is adhered onto the anti-overflow probe in the processing procedure of the food processing machine can be effectively solved, and the blending cup is easy to clean; and the anti-overflow device is integrally manufactured with the upper cover so that easiness in manufacture is achieved.

Owner:JOYOUNG CO LTD

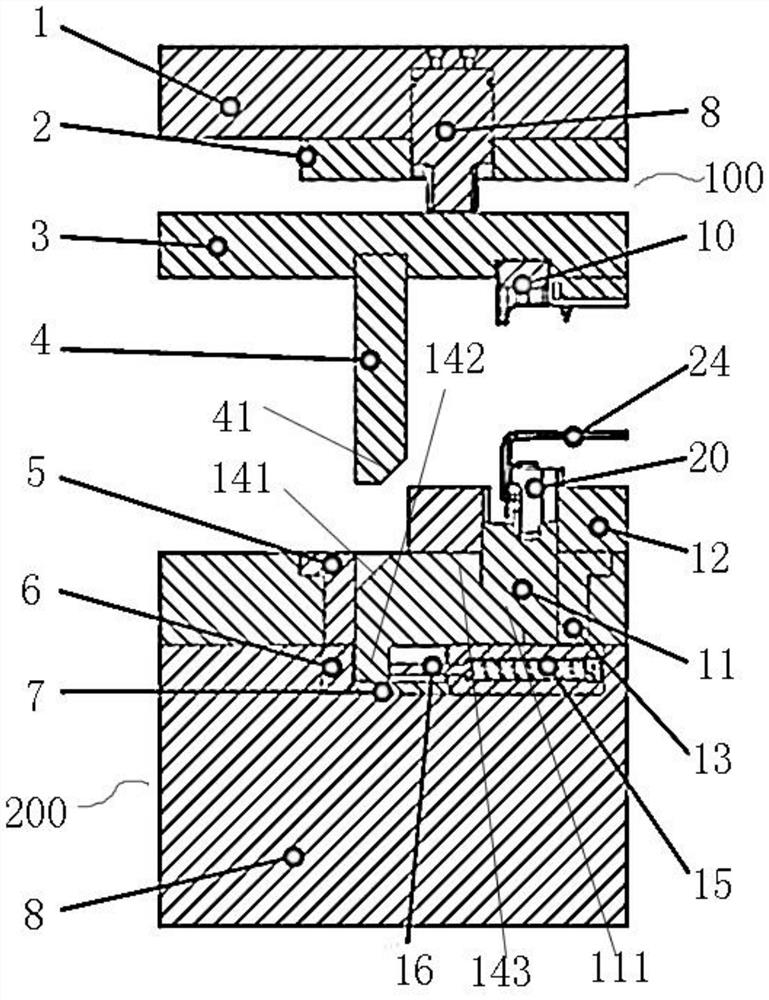

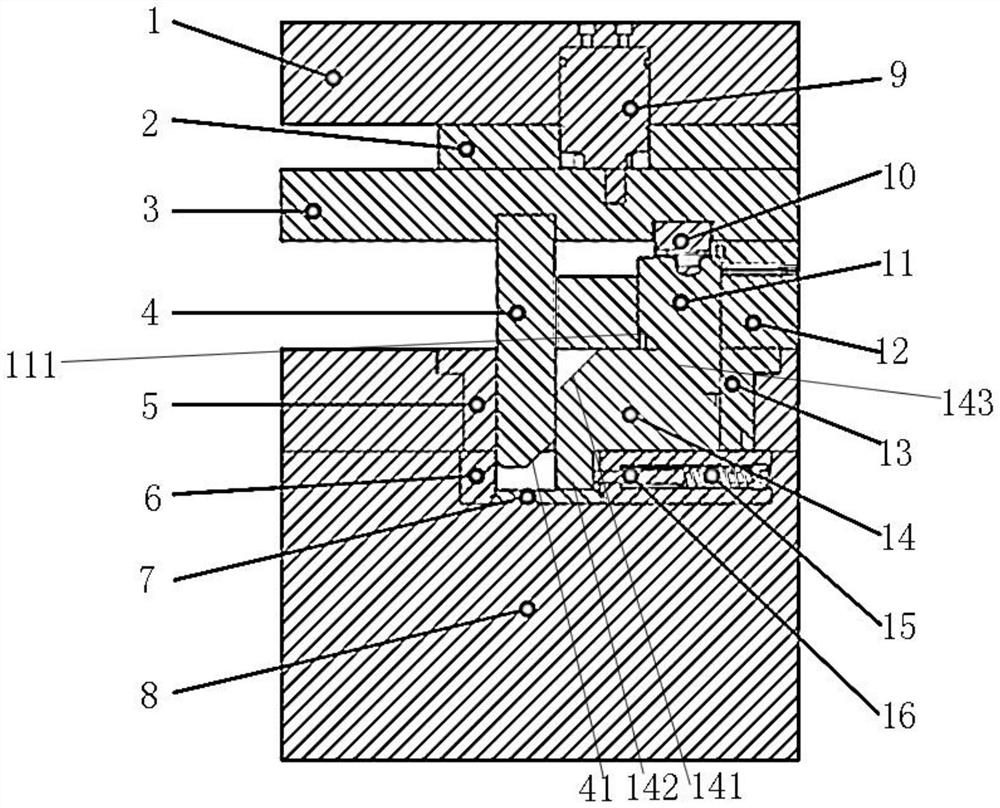

Assembly fixture for magnetic circuit structure of miniature loudspeaker

ActiveCN109068258AConsistent magnetic gapReduce the risk of badElectrical transducersLoudspeakerMagnetic circuit

The invention provides an assembly fixture for a magnetic circuit structure of a miniature loudspeaker, which is used for combining a main magnet and a main magnetic plate as a main magnet assembly, combining a sub magnet and a magnetically conductive bottom plate as a sub magnet assembly, and assembling the main magnet assembly and the sub magnet assembly into a magnetic return structure of the micro loudspeaker. According to the assembly fixture for the magnetic circuit structure of the miniature loudspeaker of the present invention, the main magnet, the main magnet plate, the sub magnet andthe magnetic conductivity base plate can be assembled at one time under precise alignment, and a consistent magnetic gap can be maintained, and the magnetic gap can be cooperated with an automated production process, thereby reducing the risk of bad operation and achieving the effect of increasing production efficiency.

Owner:东莞顺合丰电业有限公司

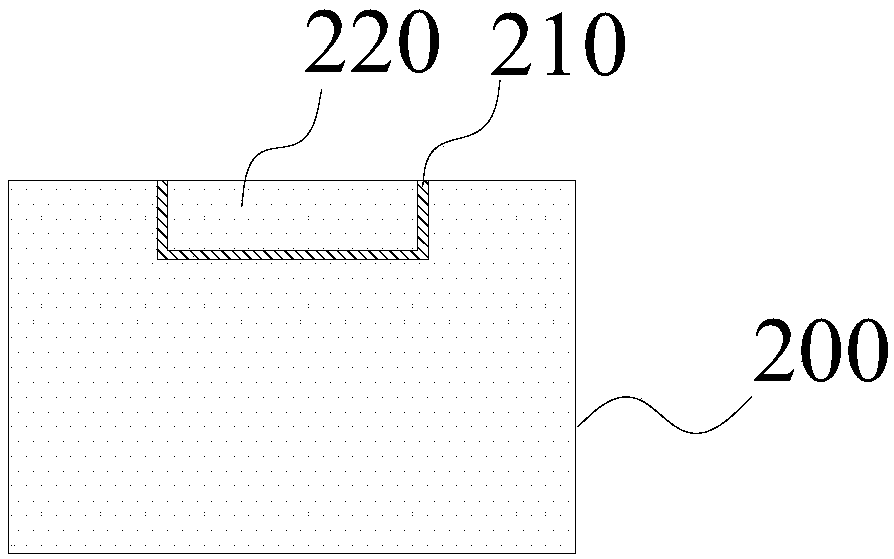

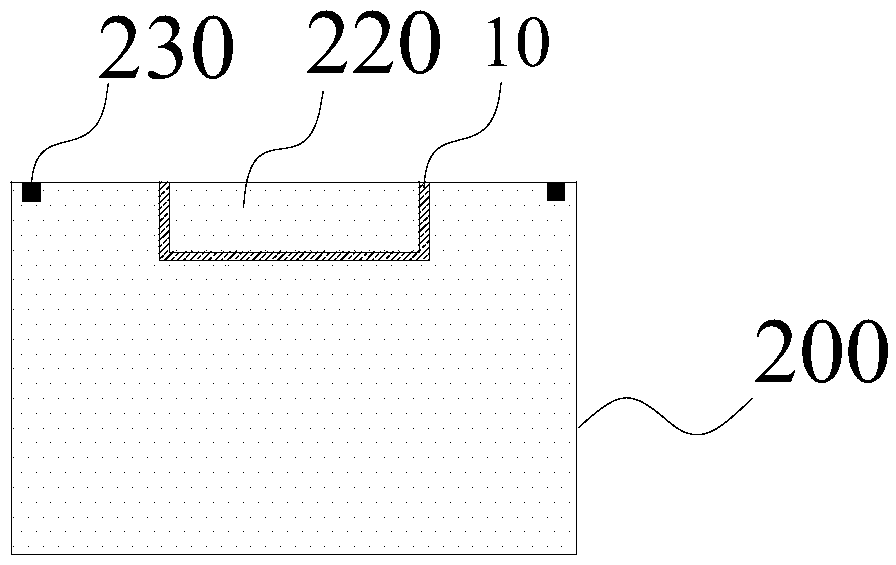

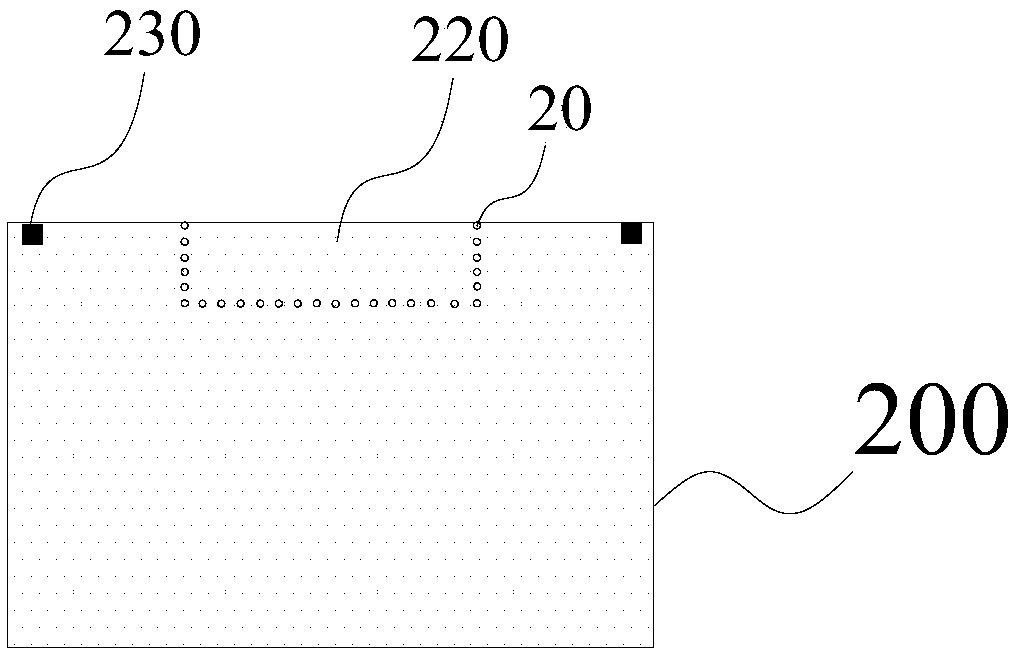

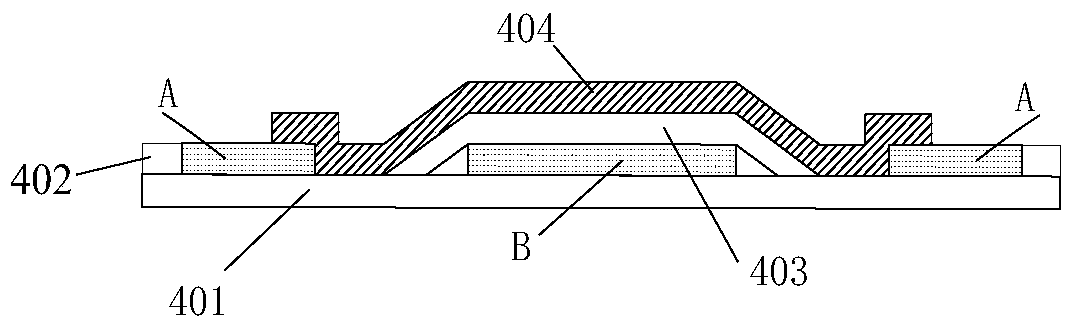

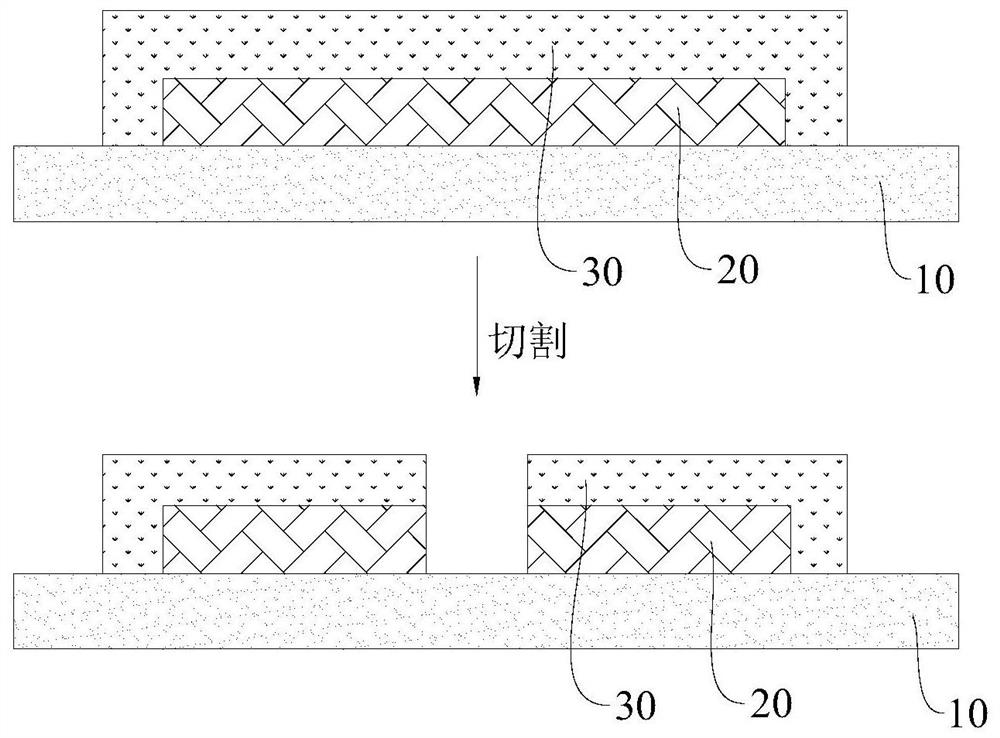

Chip on film substrate, display panel and preparation method thereof, and display device

ActiveCN109143644AMaximize screen-to-body ratioEasy to useSemiconductor/solid-state device detailsSolid-state devicesChip on filmDisplay device

The invention discloses a chip on film substrate, a display panel and a preparation method thereof, and a display device. According to the embodiment of the invention, the edge of the chip on film substrate is provided with a cut mark, wherein the cut mark defines a trenching area at the edge of the chip on film substrate. Thus, when the display panel is formed by using the chip on film substrate,the chip on film substrate can be fixed to a substrate of a display module by only one alignment, and the process is simple and the production efficiency is high; and moreover, the alignment accuracyis high, and the dislocation problem caused by corner warping of the trenching area in the alignment process is avoided, the product yield is improved, and the product adverse risk is reduced.

Owner:BOE TECH GRP CO LTD +1

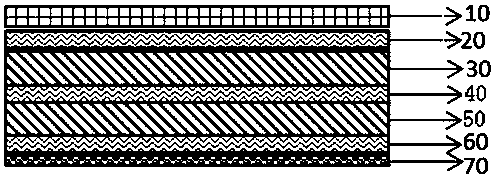

Automobile interior ceiling with high strength and high sound absorption performance and preparation method thereof

InactiveCN107891639AHigh strengthEnhanced sound absorption and noise reduction performanceSynthetic resin layered productsLaminationFiberGlass fiber

The invention discloses an automobile interior ceiling with high strength and high sound absorption performance and a preparation method thereof. The ceiling is characterized in that the ceiling is prepared through mould pressing and compounding of a back-layer non-woven fabric layer (70), a third rubber-glass layer (60), a second PU layer (50), a second rubber-glass layer (40), a first PU layer (30), a first rubber-glass layer (20) and a surface decoration layer (10); the density of the first PU layer is greater than that of the second PU layer. The preparation method comprises the steps thatglass fiber felt is coated with polyurethane rubber to prepare the rubber-glass layers, and the automobile interior ceiling is manufactured through heat molding; the PU layers with different densities can absorb noise in different frequency bands, and the sound absorption and noise reduction functions are enhanced. The ceiling is good in strength and good in sound absorption performance.

Owner:YANTAI ZHENGHAI HIGH TECH

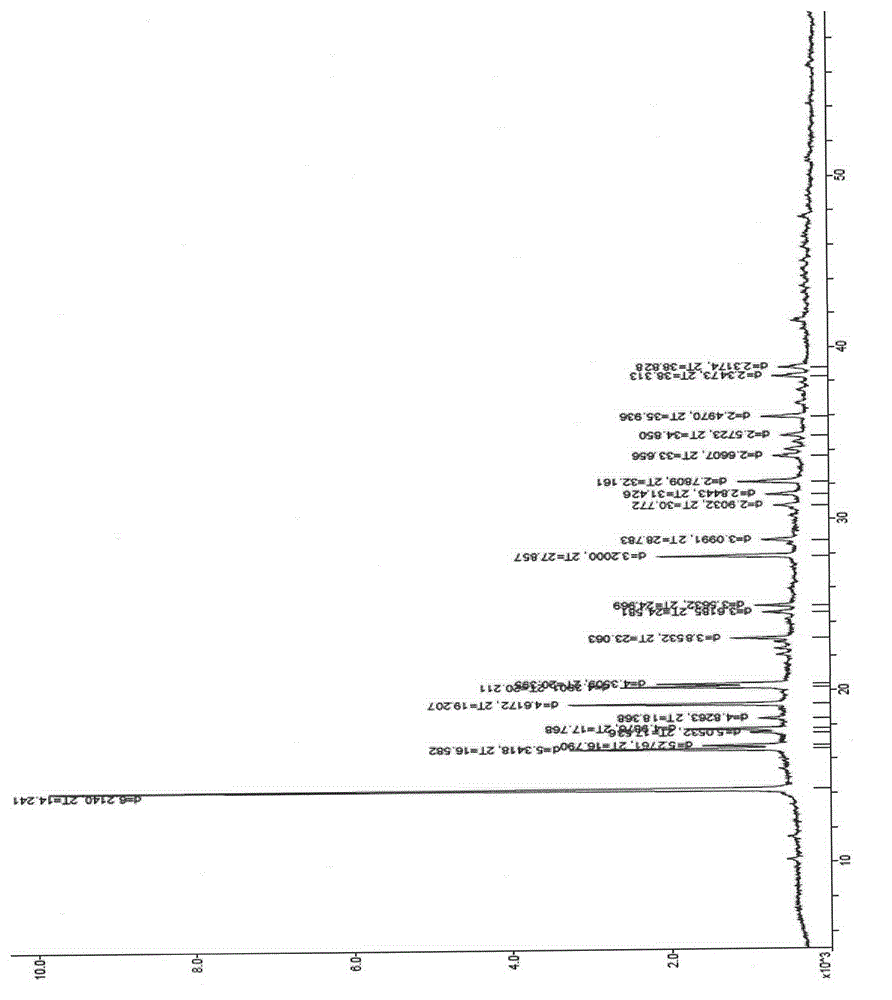

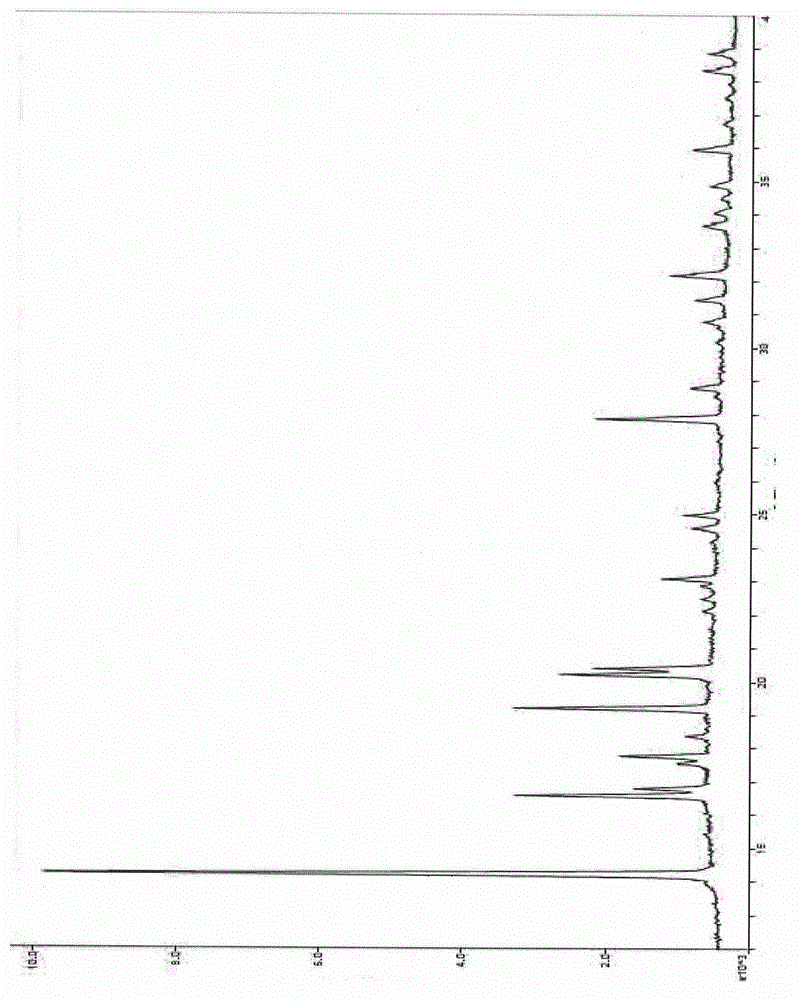

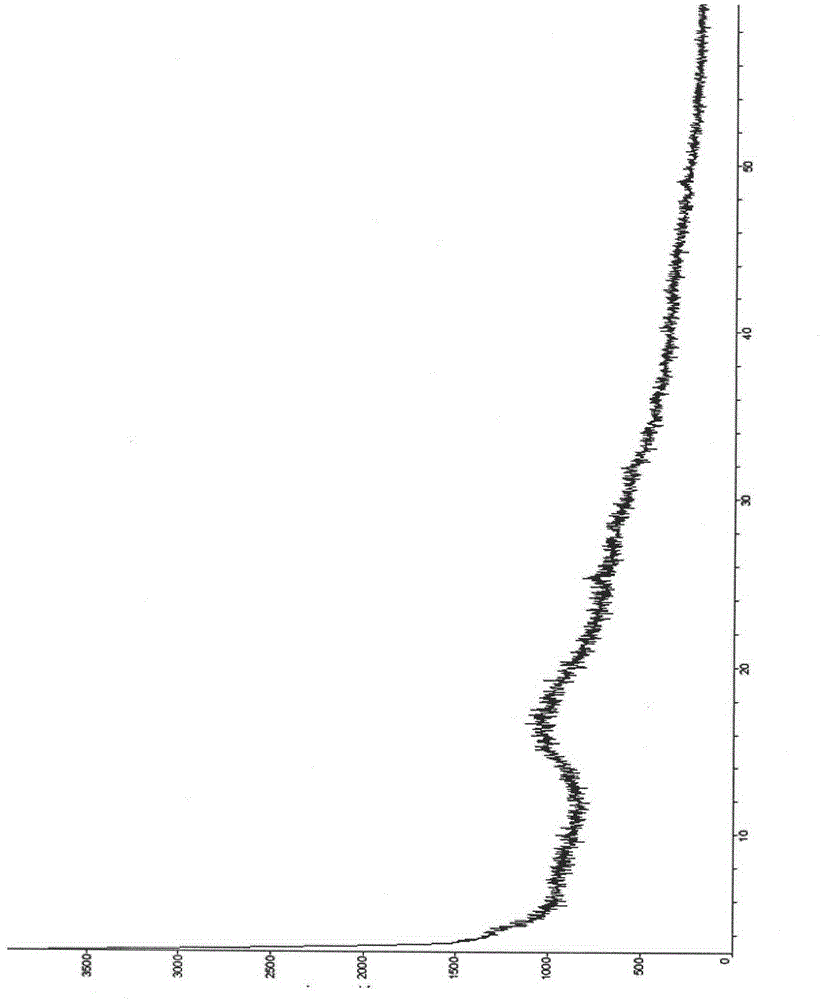

Eutectic of Piperacillin sodium and Sulbactam sodium, preparation method thereof, pharmaceutical composition containing eutectic and application of pharmaceutical composition

ActiveCN102898438BImprove stabilityExtend your lifeAntibacterial agentsOrganic chemistrySolubilityX-ray

The invention relates to an eutectic of Piperacillin sodium and Sulbactam sodium, a preparation method thereof, a pharmaceutical composition containing the eutectic and an application of the pharmaceutical composition on treating infection of super bacteria producing NDM-1 and other drug-resistance bacteria. The eutectic of the Piperacillin sodium and the Sulbactam sodium comprises diffraction angles of 14.24 DEG, 16.58 DEG, 16.79 DEG, 17.77 DEG, 19.20 DEG, 20.21 DEG, 20.39 DEG, 23.06 DEG, 27.86 DEG and 32.16 DEG represented by 2[theta] in an X-ray powder diffraction analysis spectra. The eutectic provided by the invention is excellent in solubility, low in hygroscopicity, relatively small in powder volume, high in purity, low in content of related substances, and easy to filter and dry during industrial production. A compound preparation prepared by the eutectic has obviously improved stability; not only is the shelf life of the products prolonged, but also the product safety is improved, thereby reducing potential adverse risks of the drugs and further protecting the health of patients.

Owner:XIANGBEI WELMAN PHARMA CO LTD

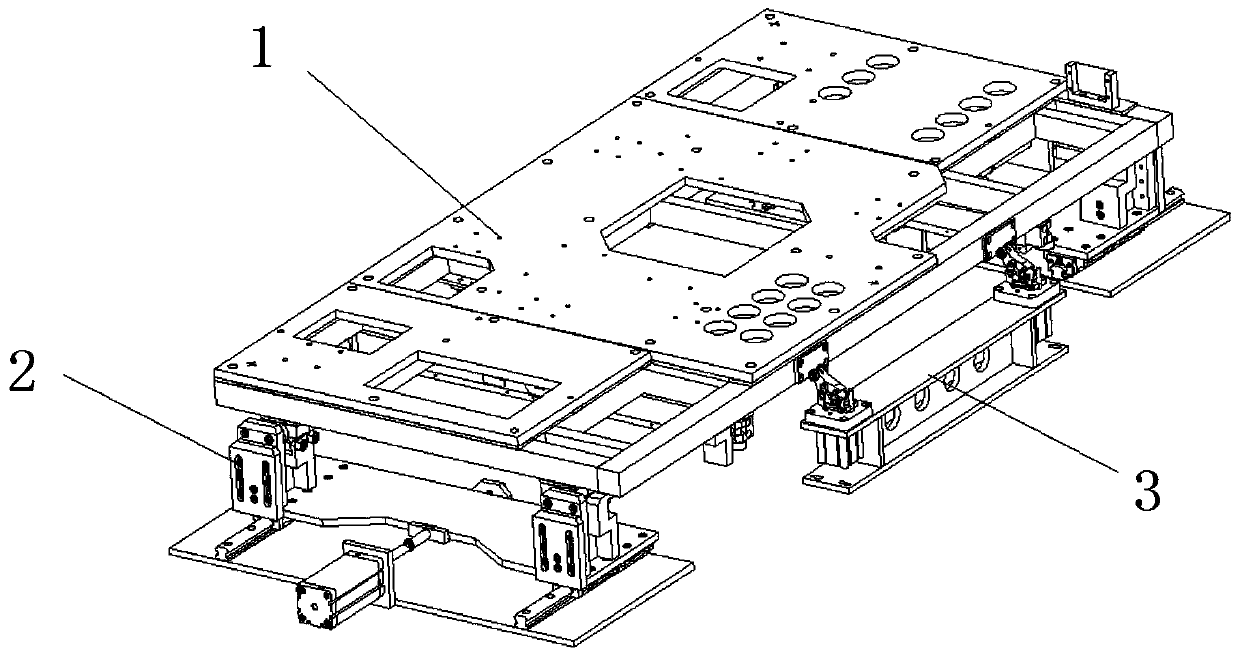

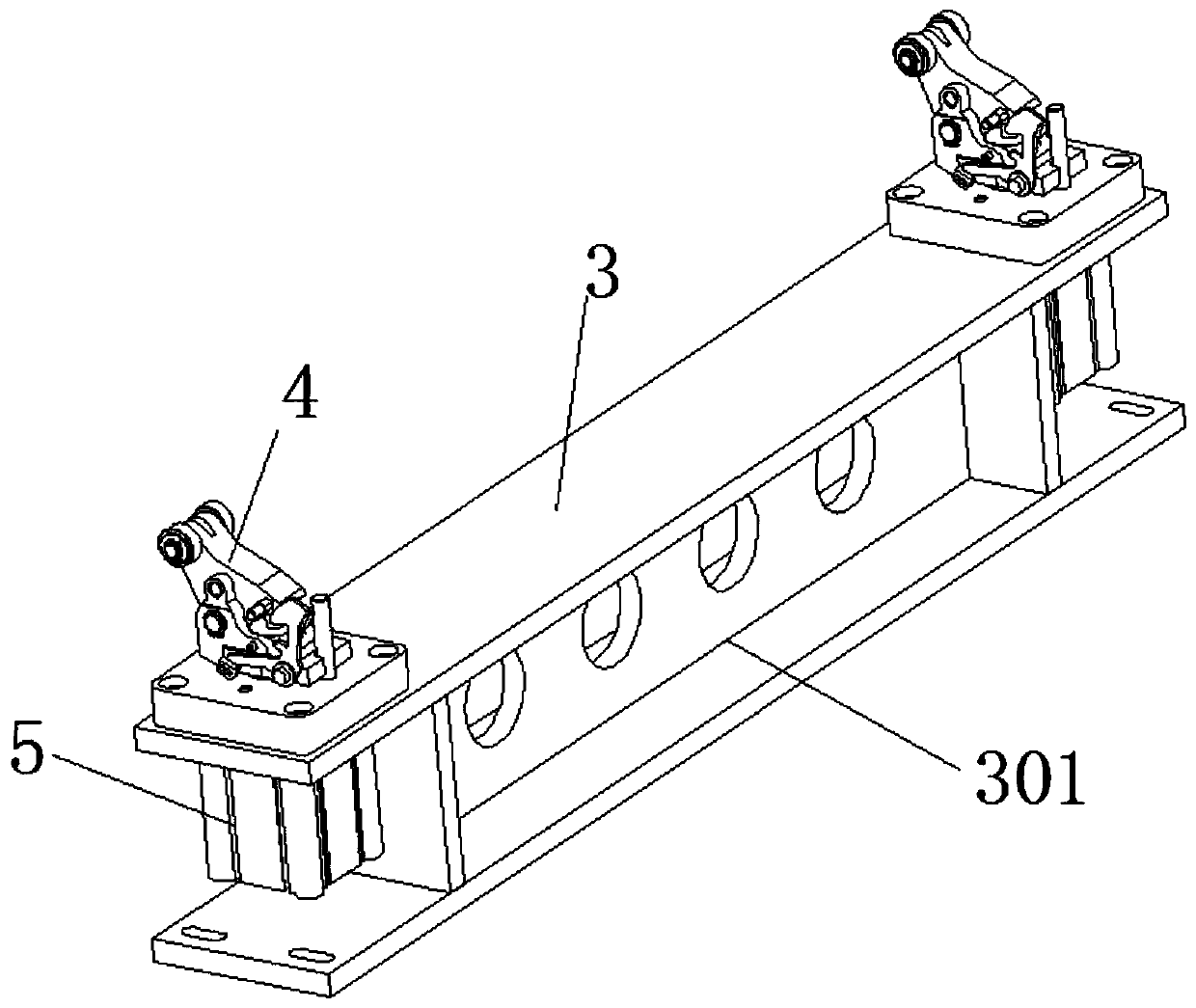

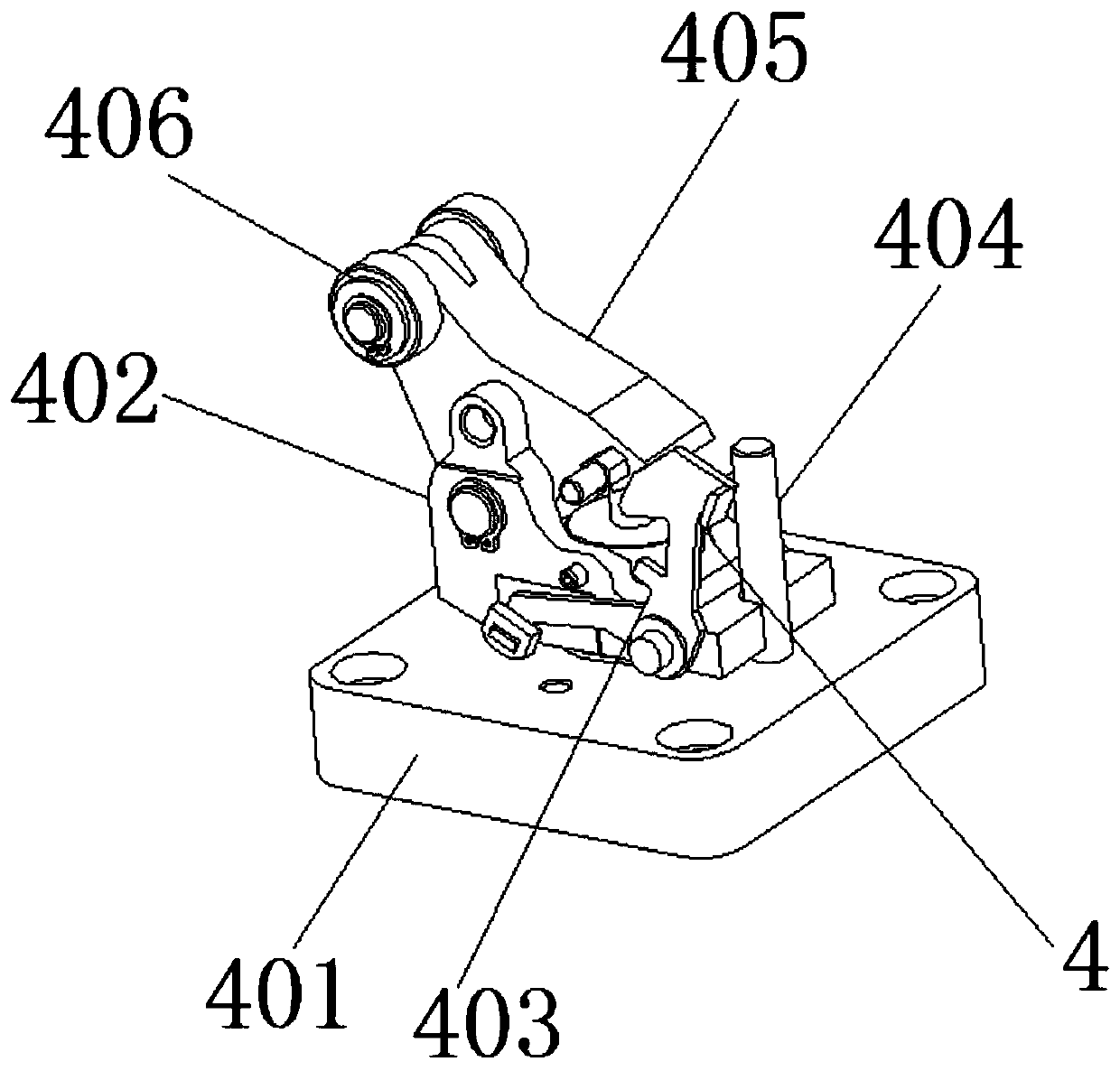

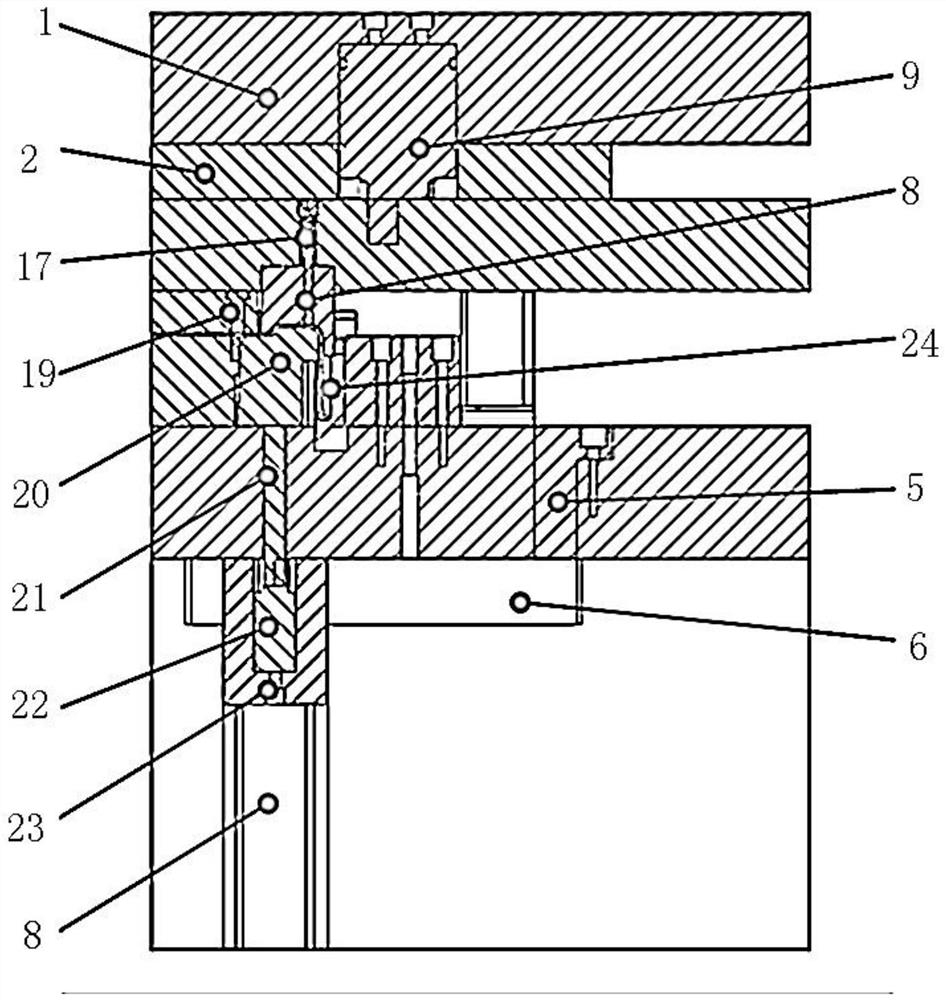

Double-speed chain tool plate positioning device

ActiveCN111015265AHigh positioning accuracyLarge bearing capacity in all directionsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFuel tank

The invention discloses a double-speed chain tool plate positioning device. The device comprises a tool plate, lifting positioning mechanisms and a stop mechanism. According to the device, a tool plate running on a double-speed chain is blocked through the stop mechanism, the lifting positioning mechanisms at the two ends are pushed under the driving of pushing air cylinders, a bearing and a positioning pin are matched with a positioning block on the tool plate, the propelling action is stopped under the action of mechanical limiting, after the working procedure of the station is completed bythe tool plate, the lifting positioning module returns under the action of the air cylinders, the stop mechanism descends, the tool plate makes contact with a transmission part of the double-speed chain again, and then the tool plate moves to the next station. The repeated positioning precision of the device is high, and the risk of product badness caused by abrasion of the contact part of the tool plate or the double-speed chain can be reduced. The device is suitable for production of a fuel tank.

Owner:WUHAN YAPP AUTOMOTIVE PLASTIC PARTS

membrane switch

ActiveCN105655178BReduce the risk of badSimple processContact with seperate bridge contactElectric switchesElectrical conductorMembrane switch

The invention discloses a membrane switch. The membrane switch comprises an upper electric-conduction layer, a lower electric-conduction layer and an insulating layer located between the upper electric-conduction layer and the lower electric-conduction layer, wherein one of the upper electric-conduction layer and the lower electric-conduction layer includes an electric-conduction circuit layer as well as a positive pole triggering part and a negative pole triggering part which are arranged on the electric-conduction circuit layer, and the other electric-conduction layer includes a first base material layer and an electric conductor which is arranged on the first base material layer and is in conduction with the positive pole triggering part and the negative pole triggering part. According to the membrane switch of the invention, the positive pole triggering part and the negative pole triggering part are simultaneously arranged on the upper electric-conduction layer or the lower electric-conduction layer, and the corresponding upper electric-conduction layer or the lower electric-conduction layer is provided with the electric conductor with an electric-conduction function. When the membrane switch is pressed, the electric conductor simultaneously contacts with the positive pole triggering part and the negative pole triggering part, a positive pole and a negative pole are conducted, and the switch is switched on. According to the membrane of the invention, only one electric-conduction circuit layer is needed to be arranged on the layer which is provided with the positive pole triggering part and the negative pole triggering part, and therefore, compared with a traditional membrane switch, the membrane switch of the invention has the advantages of simple process and high production efficiency; and just a single circuit layer is adopted, so that production cost can be greatly reduced.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

OLED display panel and manufacturing method thereof

ActiveCN110176555ASimple methodEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingHydrophilic hydrophobicEngineering

The invention provides an OLED display panel and a manufacturing method thereof. The method for manufacturing the OLED display panel comprises the following steps that a substrate is provided, whereinthe substrate is divided into a through hole area; a hydrophilic-hydrophobic transition layer is formed in the through hole area; the surface state of the hydrophilic-hydrophobic transition layer isa in a hydrophilic state; a plurality of OLED devices are formed on the surface of the substrate, wherein a gap is formed between the orthographic projections of the plurality of OLED devices on the substrate and the orthographic projection of the through hole area on the substrate; a packaging layer is formed on the surfaces of the OLED devices, the surface of the hydrophilic-hydrophobic transition layer and the exposed surface of the substrate; the state of the hydrophilic-hydrophobic transition layer on the surface of the through hole area is changed from the hydrophilic state into the a hydrophobic state; and the hydrophilic-hydrophobic transition layer and the packaging layer are removed, wherein the orthographic projection of the hydrophilic-hydrophobic transition layer on the substrate is overlapped with the orthographic projection of the through hole area on the substrate. Therefore, the hydrophilic-hydrophobic transition layer corresponding to the through hole area and the packaging layer can be removed in a relatively easy, quick and complete mode, so that the formation of a subsequent through hole is facilitated; and the process is simple, and the adverse risk in manufacturing can be reduced.

Owner:BOE TECH GRP CO LTD +1

OLED display panel and manufacturing method thereof

ActiveCN110176555BSimple methodEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingHydrophilic hydrophobicMaterials science

The invention provides an OLED display panel and a manufacturing method thereof. The method for manufacturing an OLED display panel includes: providing a substrate, on which a through-hole area is divided; forming a hydrophilic-hydrophobic transition layer in the through-hole area, and the surface state of the hydrophilic-hydrophobic transition layer is a hydrophilic state; A plurality of OLED devices are formed on the substrate, and there are gaps between the orthographic projections of the plurality of OLED devices on the substrate and the orthographic projection of the through hole area on the substrate; on the surface of the OLED device, the surface of the hydrophilic-hydrophobic transition layer, and the exposed surface of the substrate Form an encapsulation layer on the surface; make the state of the hydrophilic-hydrophobic transition layer on the surface of the through hole area change from a hydrophilic state to a hydrophobic state; Water-hydrophobic transition layer and encapsulation layer. As a result, the hydrophilic-hydrophobic transition layer and encapsulation layer corresponding to the through-hole area can be removed easily, quickly and completely, so as to facilitate the formation of subsequent through-holes; and the process is simple, which can reduce the risk of defects in manufacturing.

Owner:BOE TECH GRP CO LTD +1

Anti-corner-bending-cracking die

PendingCN112605262AReduce float heightReduce the risk of badShaping toolsStructural engineeringNitrogen gas

The invention provides an anti-corner-bending-cracking die. The anti-corner-bending-cracking die can meet the requirement for the height of a covered edge of a product without affecting strength of the product. The anti-corner-bending-cracking die comprises an upper die part and a lower die part, wherein the upper die part comprises an upper die base, a clamping plate, a large stripper plate, a forming slotting tool and an upper die pressing-in block, the clamping plate is arranged on the lower surface of the upper die base, a first nitrogen spring is fixedly arranged on the upper die base, the lower end of the first nitrogen spring penetrates through the clamping plate and then is connected with an upper mounting groove of the large stripper plate, and the lower surface of the large stripper plate is fixedly provided with a downwards-protruding forming slotting tool and a downwards-protruding upper die pressing-in block; the lower die part comprises a lower die base and a foot pad, the lower die base is fixedly installed on the upper surface of the foot pad, an overall area of the lower die base and the foot pad corresponds to the forming slotting tool, an inner groove is formed in the area of the upper die pressing-in block, and a slotting tool leaning tool, a wear-resisting fixing block, a driving block and a punch wear-resisting guide plate are arranged in the inner groove.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

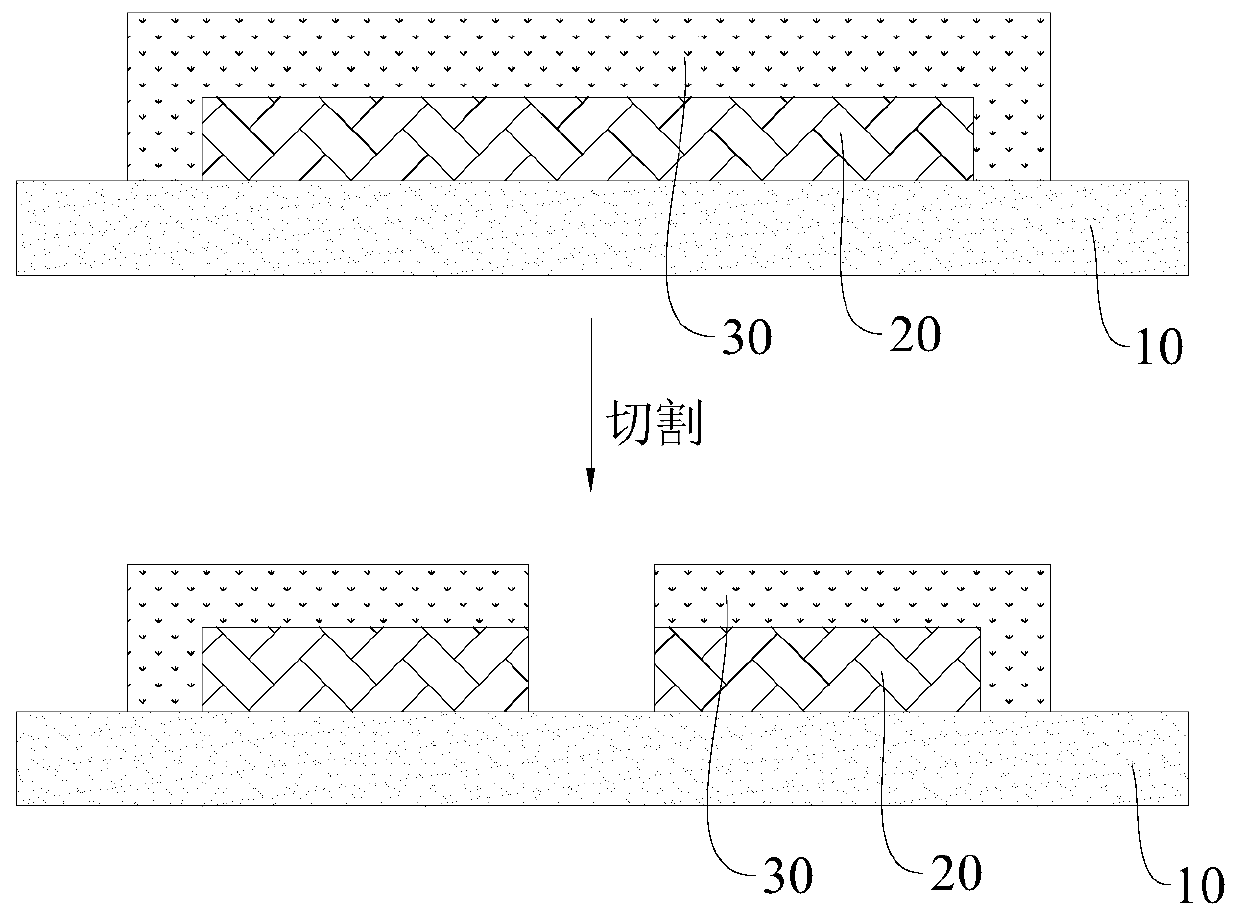

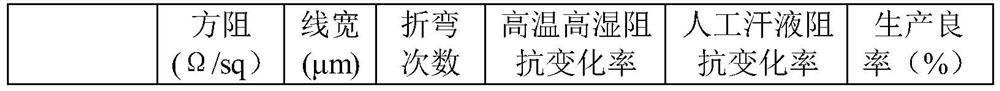

Preparation method of metal grid induction film

ActiveCN114054322AReduce the risk of badImproved ability to adhere to photoresistPretreated surfacesCoatingsPtru catalystCopper plating

The invention relates to a preparation method of a metal grid induction film, which comprises the following steps of: (1) performing corona treatment on a base film to enable the surface of the base film to reach at least 42 dynes, coating photoresist on the upper surface and the lower surface of the base film, and pre-baking to form a photoresist layer; (2) performing corona treatment on the photoresist layer to enable the surface of the photoresist layer to reach at least 40 dynes, coating a catalyst solution on the surface of the photoresist layer, and forming a catalyst layer after film formation; and (3) after double-sided exposure treatment, developing treatment is carried out to obtain a grid pattern, then copper plating treatment is carried out to form a metal grid layer, blackening treatment is carried out to form a metal grid blackening layer, and finally, protective glue is coated to form a protective glue layer, so that the metal grid induction film is prepared. According to the method, the function and performance defects caused by the bad risk of wire breakage of the metal grid can be reduced, and the production yield of products is improved.

Owner:江苏软讯科技有限公司

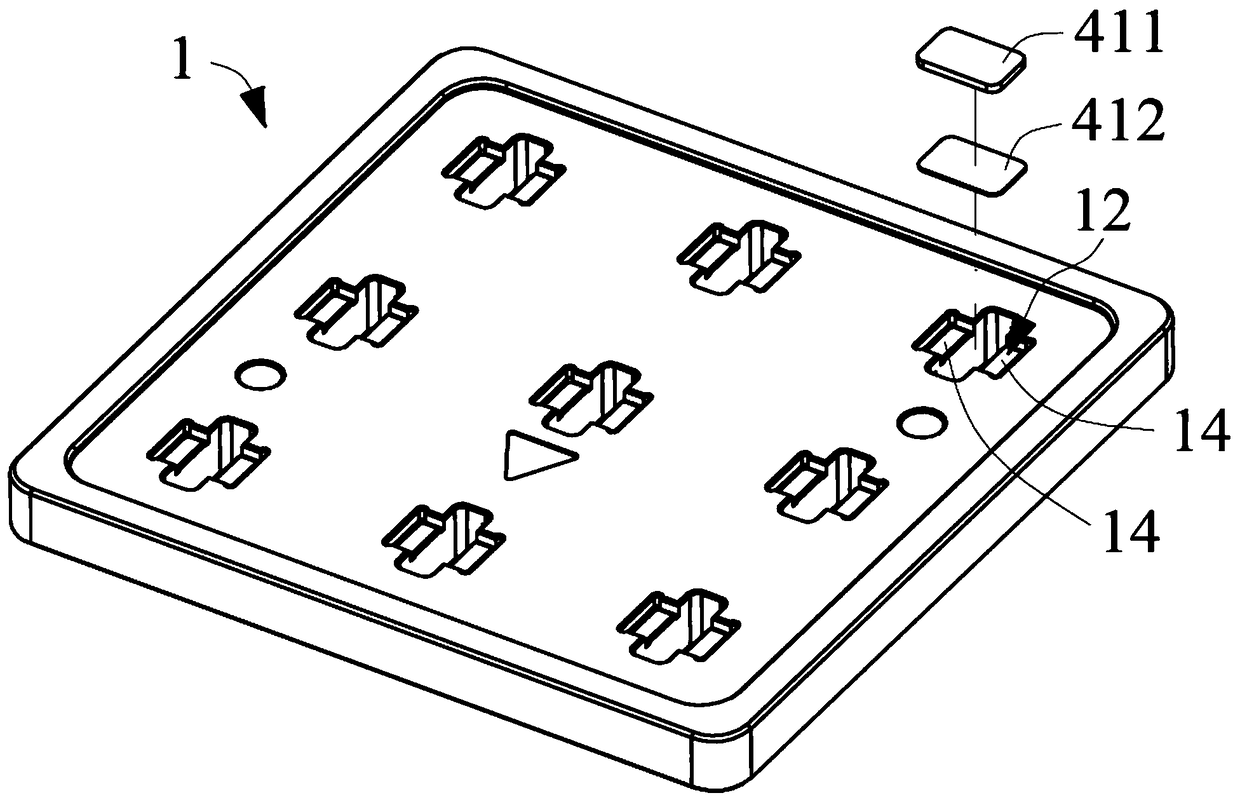

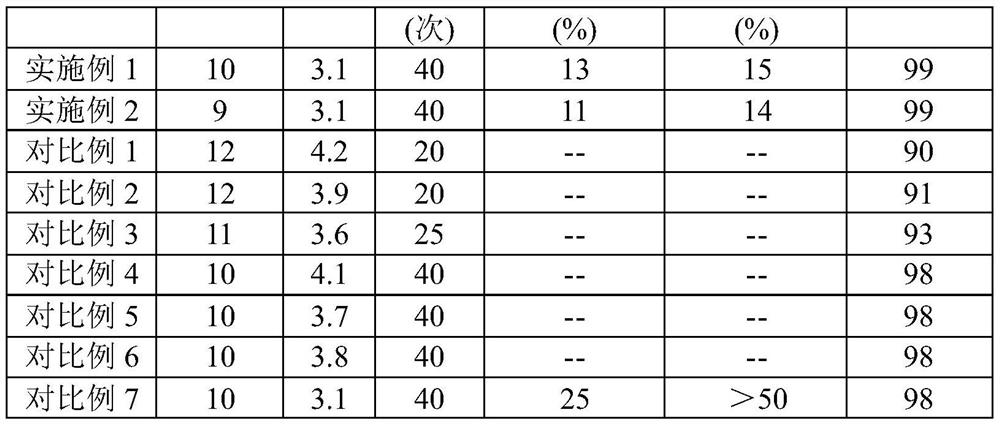

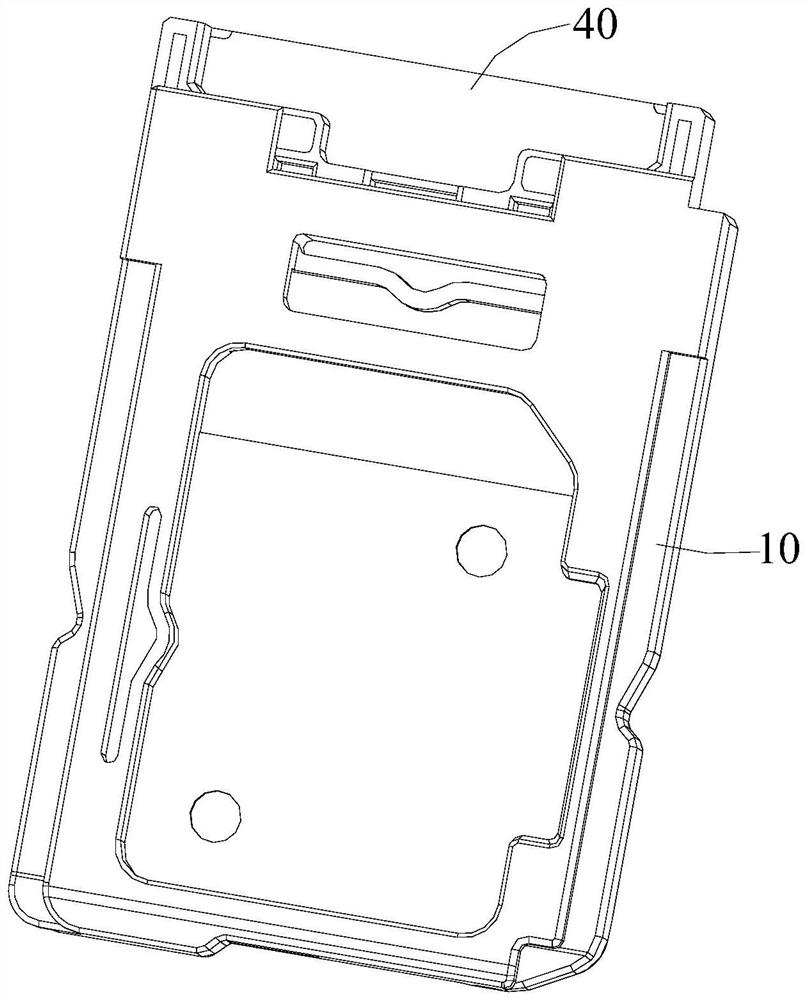

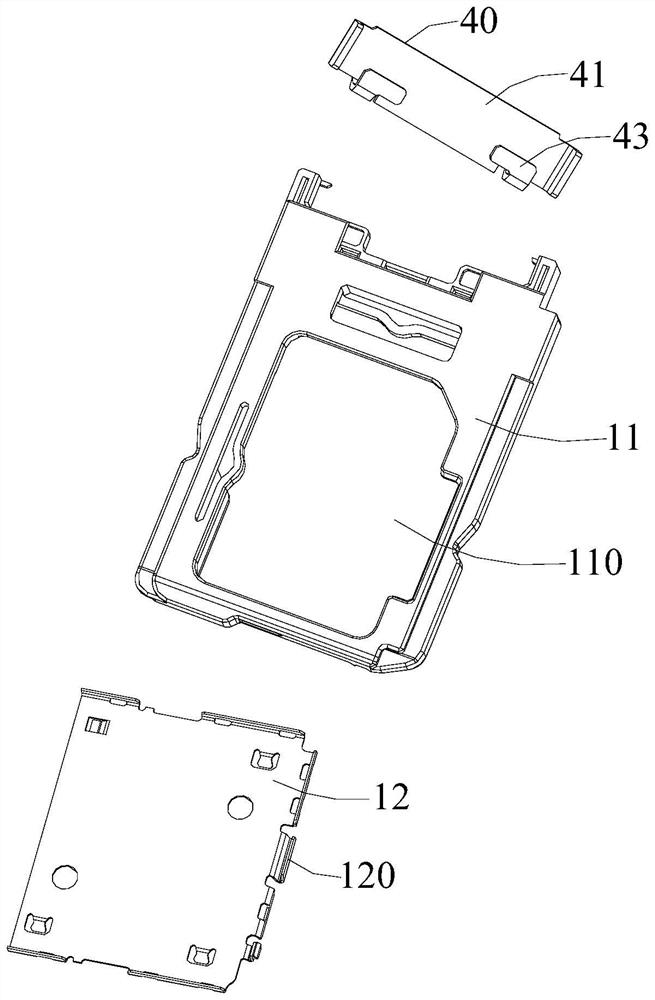

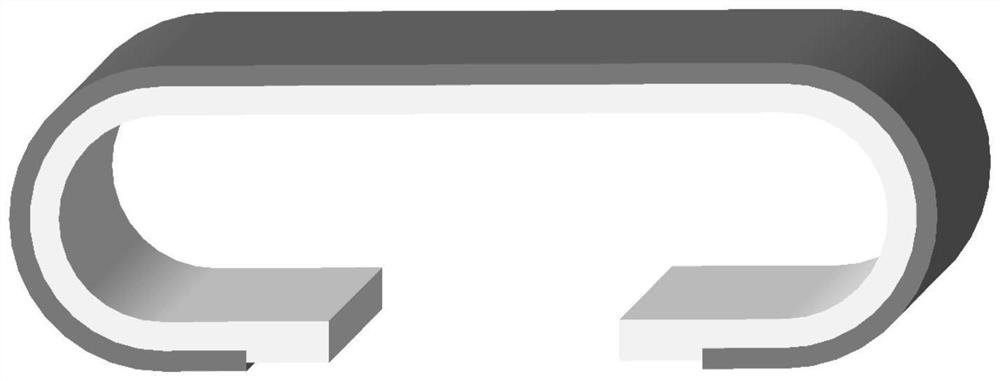

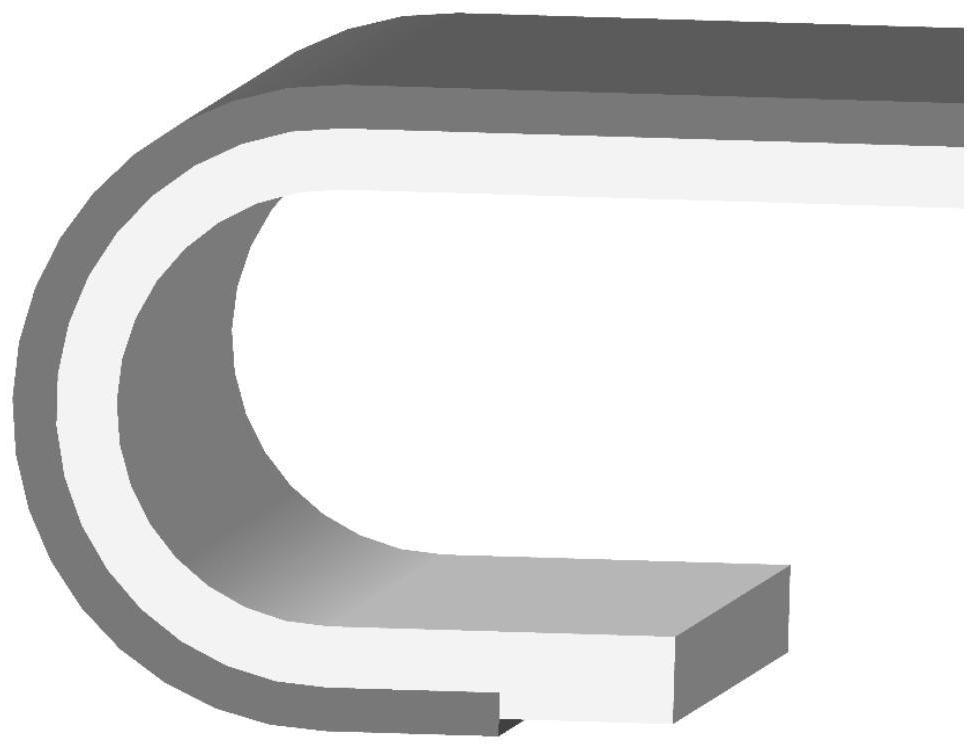

Electronic card tray and electronic assembly

PendingCN114172531AFew partsEasy to assembleTransmissionTelephone set constructionsStructural engineeringElectronic component

The invention discloses an electronic card tray and an electronic component, the electronic card tray comprises a bracket and a moving door, the bracket is provided with a clamping groove, the moving door is provided with a clamping hook buckled with electronic equipment, the moving door is movably connected with the bracket, and the moving door can move back and forth and left and right relative to the bracket. When the movable door moves left and right by a preset distance, the clamping hook is separated from the electronic equipment, the first shell is fixed on the bracket and comprises an elastic piece and a guide piece, the elastic piece forwards abuts against the movable door, the movable door is provided with an L-shaped guide groove, and the guide piece is arranged in the L-shaped guide groove. The guide sheet is limited in the guide groove to move back and forth and left and right, the electronic card tray does not need to be additionally provided with objects such as a fixed needle, the electronic card tray can be directly withdrawn from the electronic equipment by hand, and the electronic card tray is simple and convenient to use.

Owner:昆山惠乐精密工业有限公司

Bearing film and manufacturing method thereof, display module and display device

The embodiment of the invention provides a bearing film and a manufacturing method thereof, a display module and a display device. The bearing film is used for attaching a flexible display panel to a cover plate, and the bearing film comprises a first area, a second area provided with a groove and a third area; the second region is located between the first area and the third area; the first area and the third area are used for being attached to the flexible display panel, and the second area is used for being attached to the bending area of the flexible display panel at the interval of the depth of a groove formed in the bending area. The bearing film provided by the embodiment is attached to the flexible display panel, so that the bearing film is directly attached to the flexible display panel in the non-bending area and is attached to the flexible display panel at a certain distance in the bending area, the stress borne by the flexible display panel in the bending area can be reduced, the risk of poor Crack is reduced, and the 3D laminating yield is improved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com