Preparation method of metal grid induction film

A technology of metal mesh and induction film, which is used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as defects, poor quality, easy functions and performances, etc., so as to improve the production quality of products. efficiency, reducing void defects, and improving the ability to wet the photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

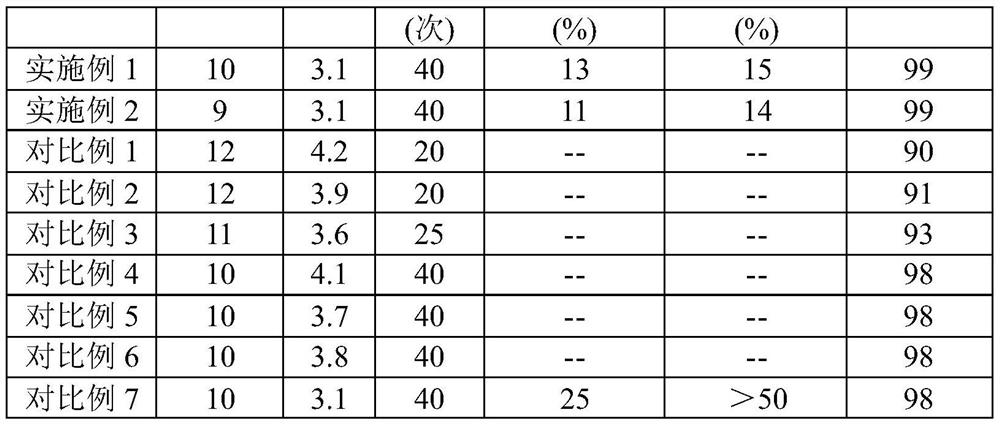

Embodiment 1

[0029] (1) Take the PET base film, and corona treat it: power 2KW, output voltage is 10KV, and the surface energy of the PET base film can reach 46 dynes, and the upper and lower surfaces of the base film are coated with a negative substance containing a photoinitiator. A photoresist with a thickness of 500nm is formed after prebaking at 120° C. for 5 minutes; a negative photoresist containing a photoinitiator includes polyisoprene, solvent xylene and photoinitiator 1-(6 -O-chlorobenzoyl-9-ethylcarbazole)-1-ethanone oxime ethyl ester, so that the viscosity after deployment is 480mPa·s, and the photoinitiator consumption is 2% of the polyisoprene quality;

[0030] (2) Corona treatment is carried out to described photoresist layer: after power 2KW, output voltage are 10KV to make photoresist layer surface can reach 42 dyne, on the surface coating catalyst solution of described photoresist layer, in After drying at 80°C for 20s, a 40nm-thick catalyst layer is formed; wherein the ...

Embodiment 2

[0037] The preparation process of this example is the same as that of Example 1, except that after the catalyst layer is formed in step (2), the biaxially stretched BOPP film is heated by double-sided hot-pressed rubber rolls at 100°C, at a speed of 10m / min, with two rolls Heat paste it on the catalyst layer under the pressure of 3KG. After heat paste, the surface hardness reaches 5b / 500g or more, which can protect the surface of the catalyst layer from water resistance, insulation, scratch resistance, and friction resistance. The intermediate products after the aforementioned operations are protected from damage during the transfer operation;

[0038] After the exposure treatment in step (3) and before the development treatment, the BOPP film needs to be peeled off at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com