Bearing film and manufacturing method thereof, display module and display device

A manufacturing method and display module technology, which are applied in the direction of identification devices, instruments, etc., can solve problems such as bad cracks, reduce stress, reduce the risk of bad cracks, and improve 3D bonding yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

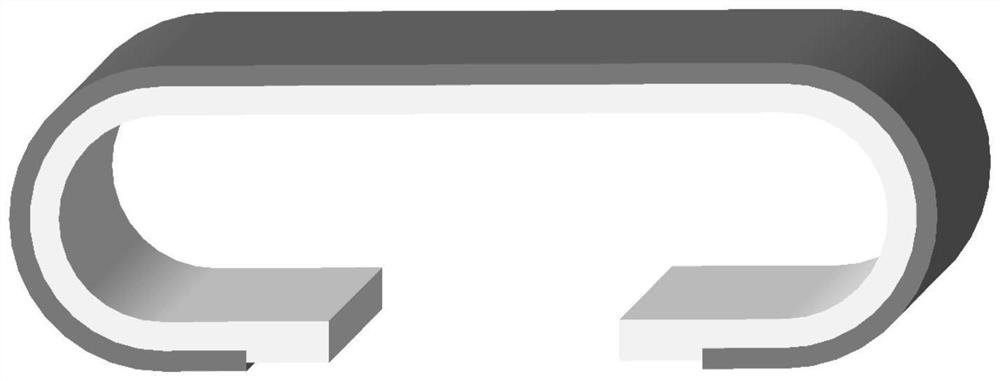

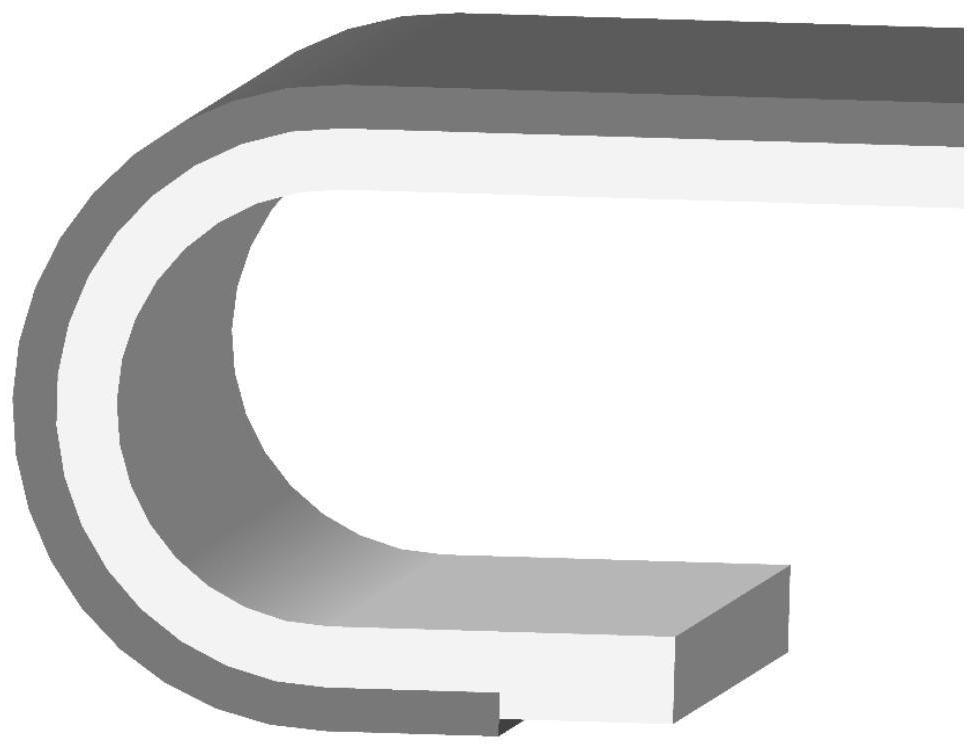

[0044] This embodiment provides a carrier film for bonding a flexible display panel to a cover plate. The structure of the carrier film is as follows: Figure 3(a) to Figure 3(d) As shown, the carrier film includes a first region 101, a second region 102 with grooves and a third region 103; the second region 102 is located between the first region 101 and the third region 103; the first region 101, the second region 103 The third area 103 is used for direct lamination with the flexible display panel, and the second area 102 is used for lamination with the bending area of the flexible display panel by the depth of the groove provided.

[0045] The carrier film in this embodiment is a special design of the carrier film structure. By digging the carrier film at the position corresponding to the bending area of the flexible display panel, the carrier film is directly attached to the flexible display panel only in the non-bending area. The display panel is attached to the flexi...

Embodiment 2

[0048] This embodiment provides a method for making a carrier film, which can be used to make the carrier film in Embodiment 1. The layer structure of the carrier film is as follows: Figure 5 As shown, the production method includes:

[0049] Step S1 , providing a carrier film substrate 11 .

[0050] In practical application, in the step S1 of making the carrier film, the carrier film base material 11 , the viscous reducing adhesive 12 and the release film 13 are provided as raw materials for future use. In some embodiments, the carrier film substrate 11 is preferably a PET substrate or a PU substrate; the adhesive 12 is a UV adhesive, such as an acrylic adhesive added with a UV initiator; the release film 13 is a PET release film. Type film or PU release film.

[0051] Step S2 , coating the adhesive 12 on the carrier film substrate 11 and drying it.

[0052] In one implementation, the step S2 coating the adhesive on the carrier film substrate includes: discontinuously coati...

Embodiment 3

[0063] This embodiment provides a display module, including:

[0064] cover;

[0065] For the flexible display panel, use the carrier film of Embodiment 1 or the carrier film obtained by the method of Embodiment 2 to bond to the cover plate.

[0066] In practical applications, the above-mentioned cover plate is a glass cover plate (Cover Glass, CG for short), and the flexible display panel can be a flexible display panel whose bending angle in the bending area is greater than 90°, especially if the bending angle in the bending area is not For flexible display panels less than 160°, for example, flexible display panels with larger bending angles of 160° and 180°, by applying the above-mentioned carrier film to flexible display panels with bending angles greater than 90° in the bending area, Can effectively reduce Crack bad.

[0067] Figure 6 It shows a schematic diagram of laminating the carrier film and the flexible display panel provided by the embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com