Anti-corner-bending-cracking die

A corner and mold technology, applied in the field of product bending, can solve the problems of increasing the number of mold repairs, product appearance inspection, difficult molding, and increasing the risk of product failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

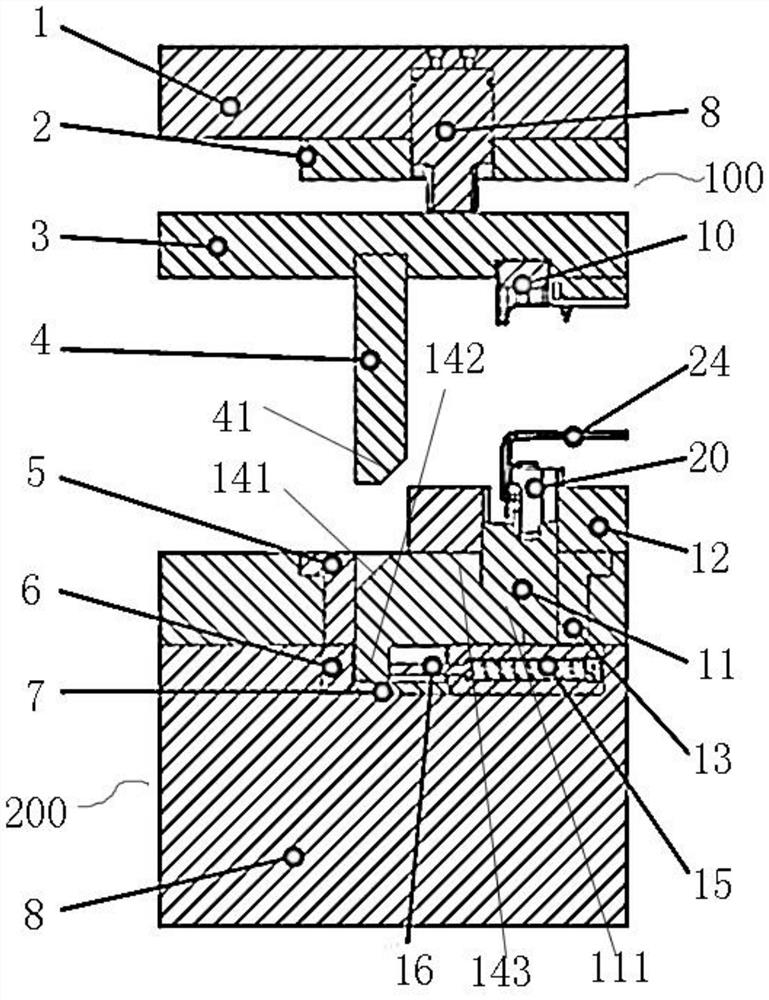

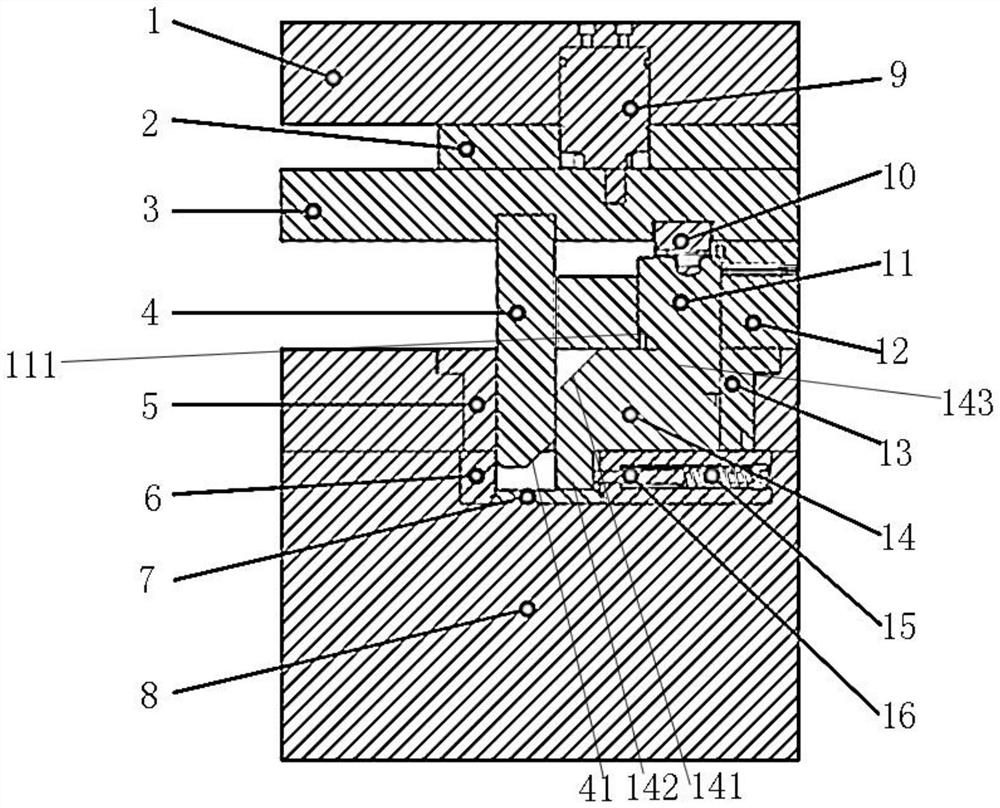

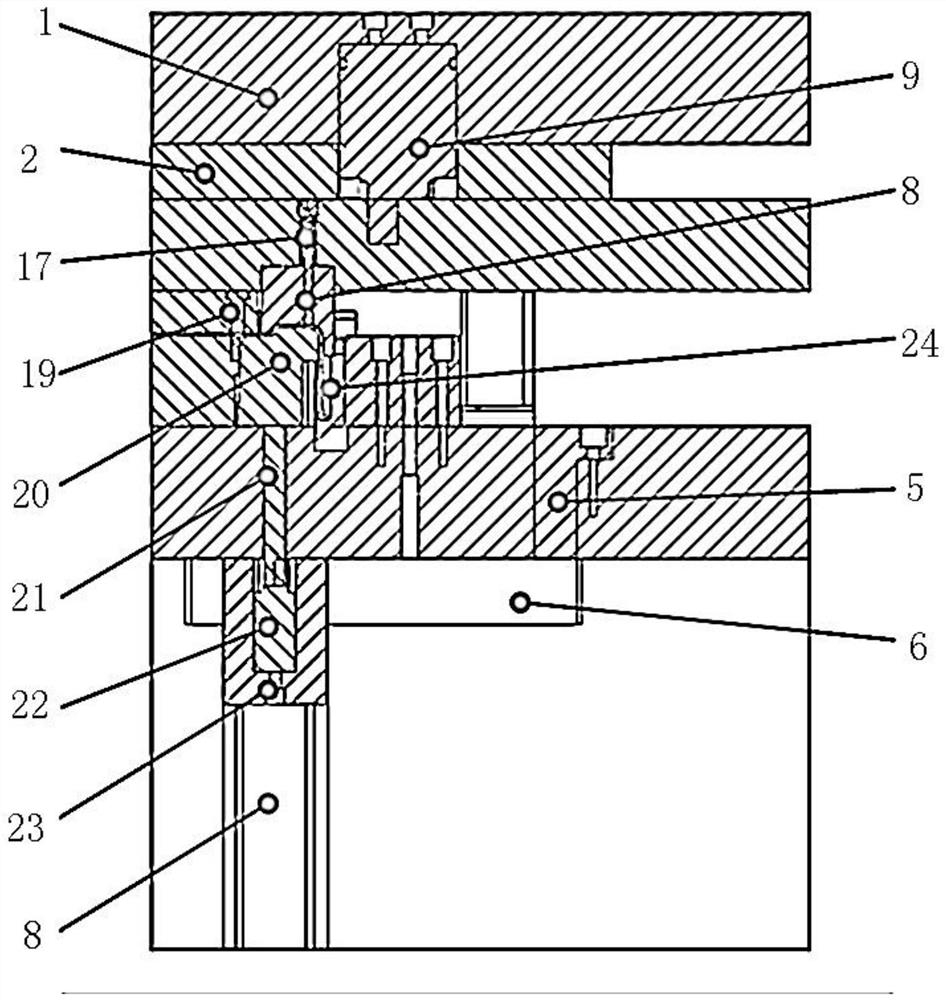

[0021] Anti-corner bending cracking die, see Figure 1-Figure 5 : It comprises upper mold part 100, lower mold part 200, upper mold part 100 comprises upper mold base 1, splint 2, large stripping plate 3, forming inserting knife 4, upper mold pressing material into block 10, the lower surface of upper mold base 1 A splint 2 is arranged, and a first nitrogen spring 9 is fixed on the upper mold base 1. The lower end of the first nitrogen spring 9 passes through the splint 2 and then connects to the upper installation groove of the large release plate 3, and the lower surface of the large release plate 3 is fixed respectively. There is a downwardly convex forming insert 4, a downwardly convex upper die press-in block 10;

[0022] The lower mold part 200 includes a lower mold base 25 and a pad 8, the lower mold base 25 is fixed on the upper surface of the pad 8, and the overall area of the lower mold base 25 and the pad 8 corresponds to the shape of the forming insert 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com