Touch panel and preparation method thereof and display device

A touch panel and touch area technology, applied in instruments, semiconductor devices, computing, etc., can solve the problem of high production cost of touch panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

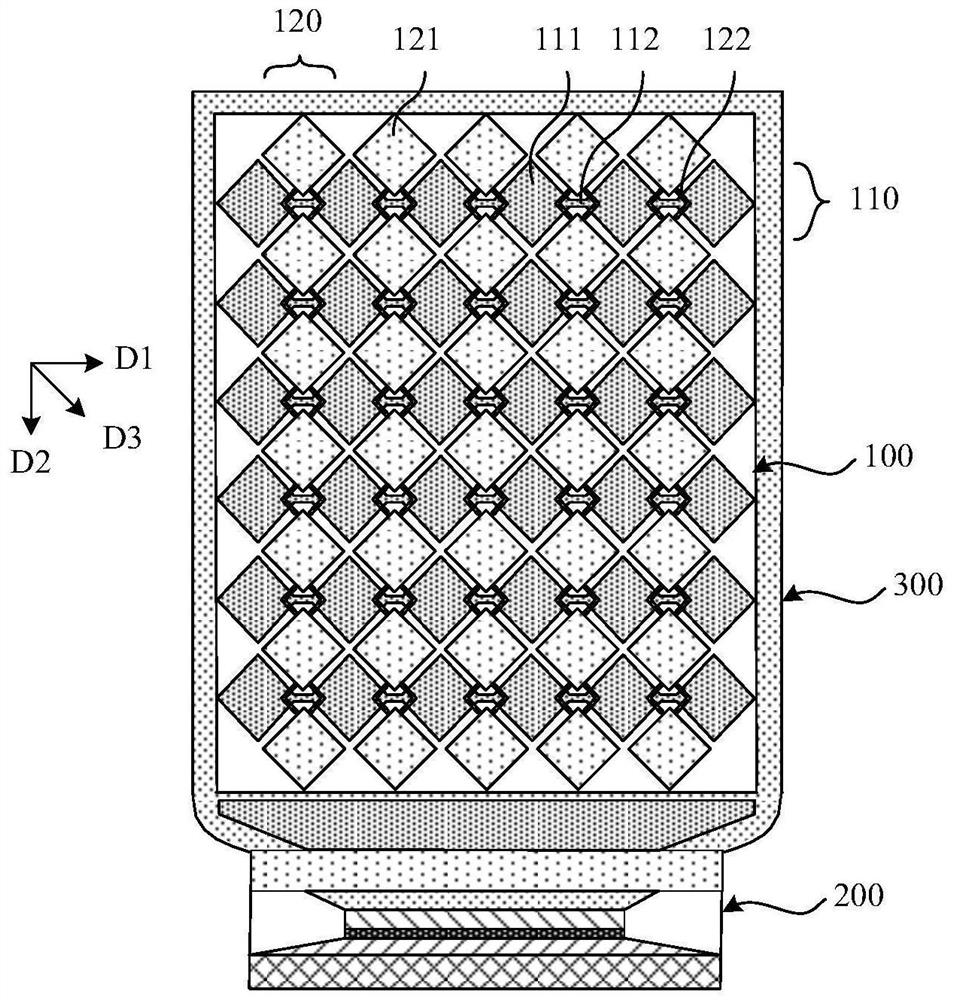

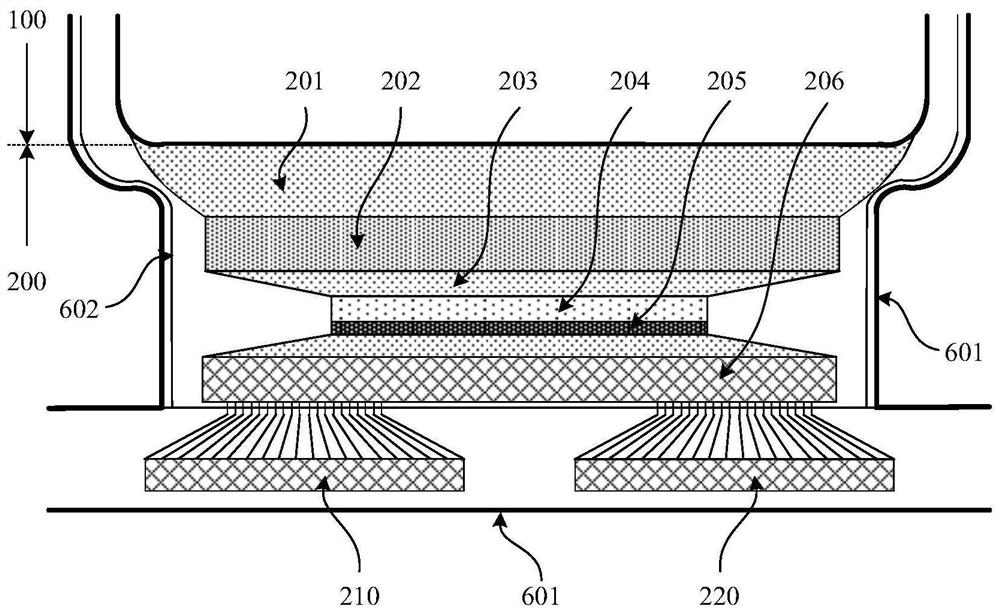

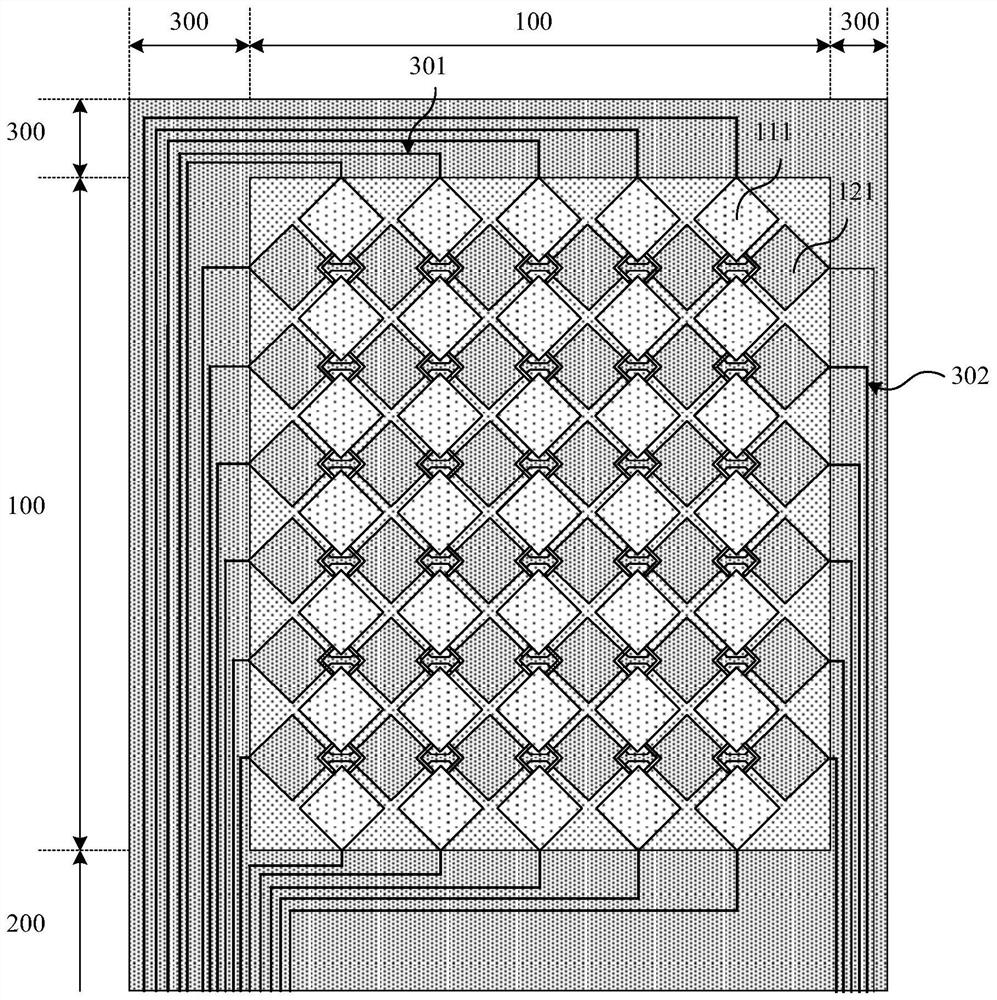

[0207] The present disclosure also provides a method for manufacturing a touch panel. The touch panel includes a display area and a binding area located on one side of the display area. Along the direction away from the touch area, the binding area includes at least The first fan-out area, the bending area, the second fan-out area, the driver chip area and the binding pin area are set; along the direction parallel to the edge of the binding area, the binding pin area includes the The first pin area on the first side of the binding area and the second pin area on the second side of the binding area, the edge of the binding area is the edge of the binding area adjacent to the touch area. In an exemplary embodiment, the preparation method includes:

[0208] A plurality of transfer wires are formed in the second fan-out area of the binding area; or, a plurality of transfer wires are formed in the outer pin bonding area between the driver chip area and the binding pin area;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com