Single body feeding and discharging machine for manufacturing LCD products

A product manufacturing and feeder technology, applied in the field of single loading and unloading machines, can solve problems such as inconvenient portability, cumbersome installation, and complex structure, and achieve the effects of improving product production efficiency, reducing product cost, and increasing production and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

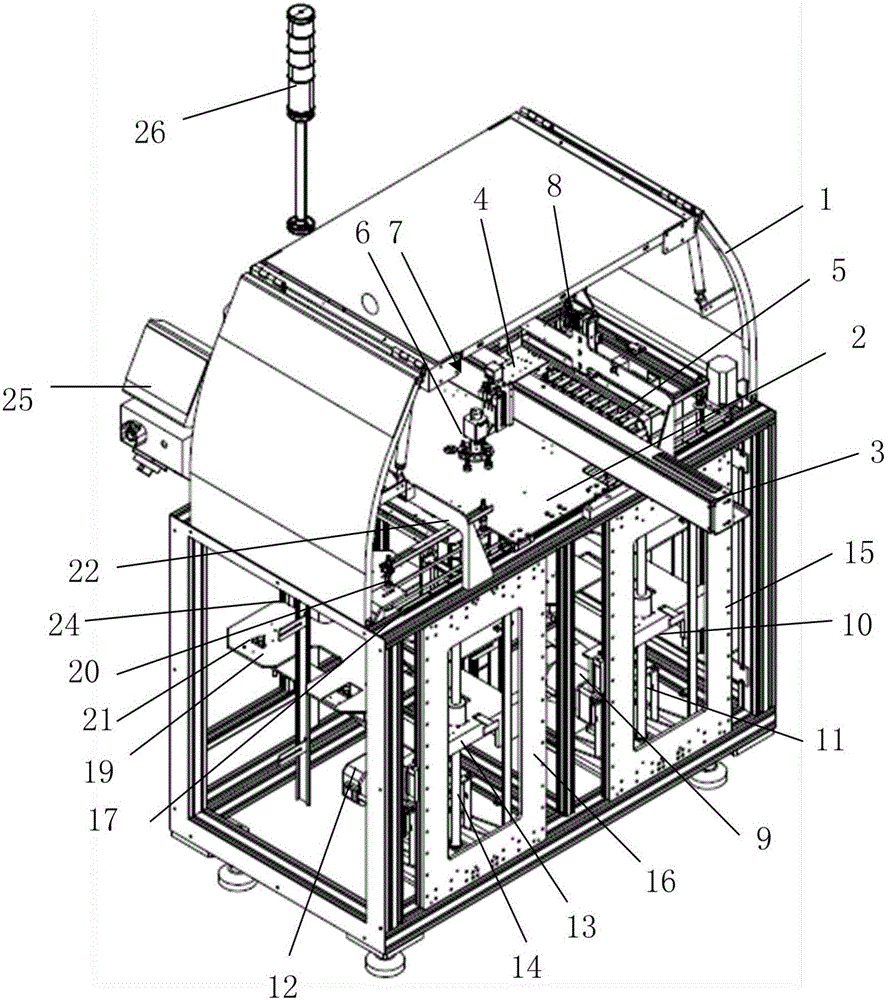

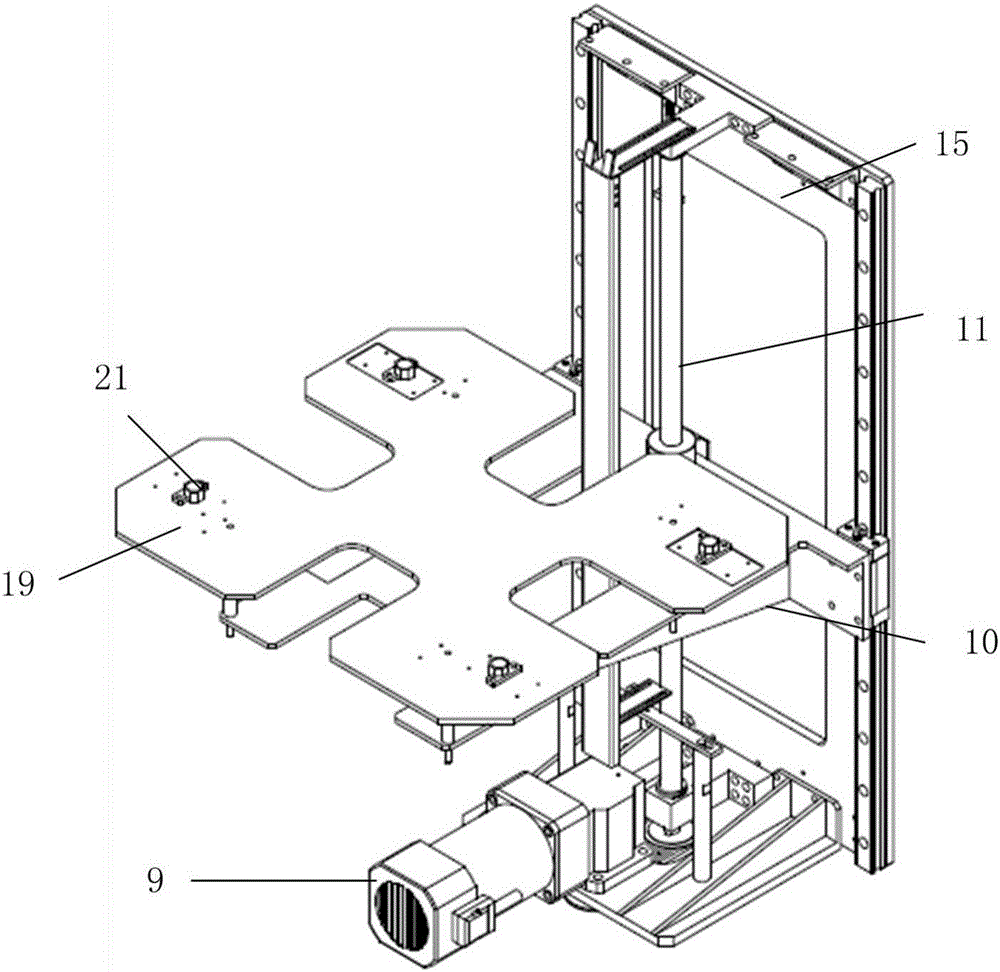

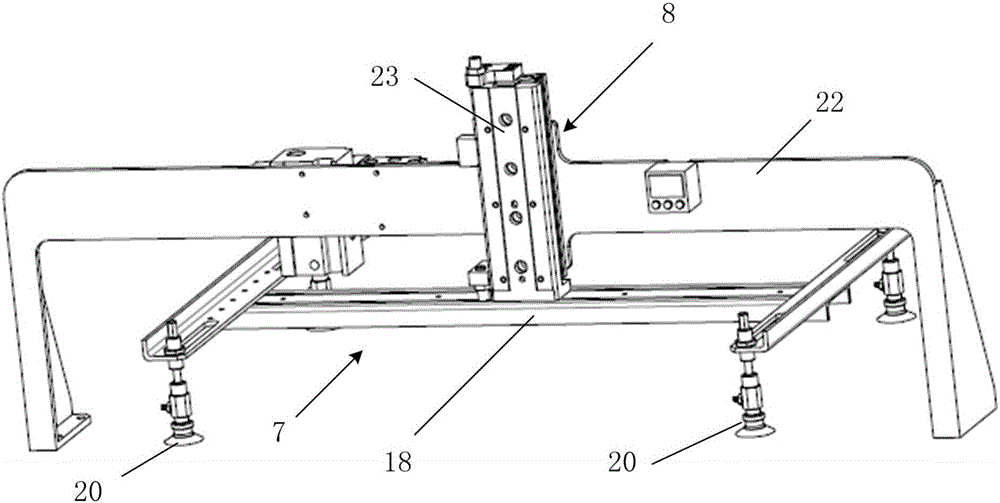

[0039] like figure 2 , image 3 , Figure 4 As shown, as a preferred embodiment of the present invention, the motor mechanism includes a first motor 9 and a second motor 12, the lift platform mechanism includes a first lift platform 10 and a second lift platform 13, and the sliding shaft mechanism Including the first sliding shaft 11 and the second sliding shaft 14, so that the lifting unit is set as an input part mechanism and a discharge part mechanism arranged horizontally side by side, that is, the input part mechanism includes a first motor 9, a first lifting platform 10 and a first sliding shaft 11, the discharge mechanism includes a second motor 12, a second lifting platform 13 and a second sliding shaft 14. Corresponding to the above design, the arrangement includes two groups of the suction units, which are respectively arranged corresponding to the input part mechanism and the discharge part mechanism. The input part mechanism is used to transfer the feeding tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com