Display substrate, manufacturing method thereof, crack detection method and display device

A display substrate, crack detection technology, applied in identification devices, electronic circuit testing, semiconductor/solid-state device components, etc., can solve the problems of easy to increase the difficulty of wiring in the edge area of the display screen, complicated operations, etc., to reduce the risk of defects , The effect of reducing the difficulty of wiring and increasing the space that can be used for wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

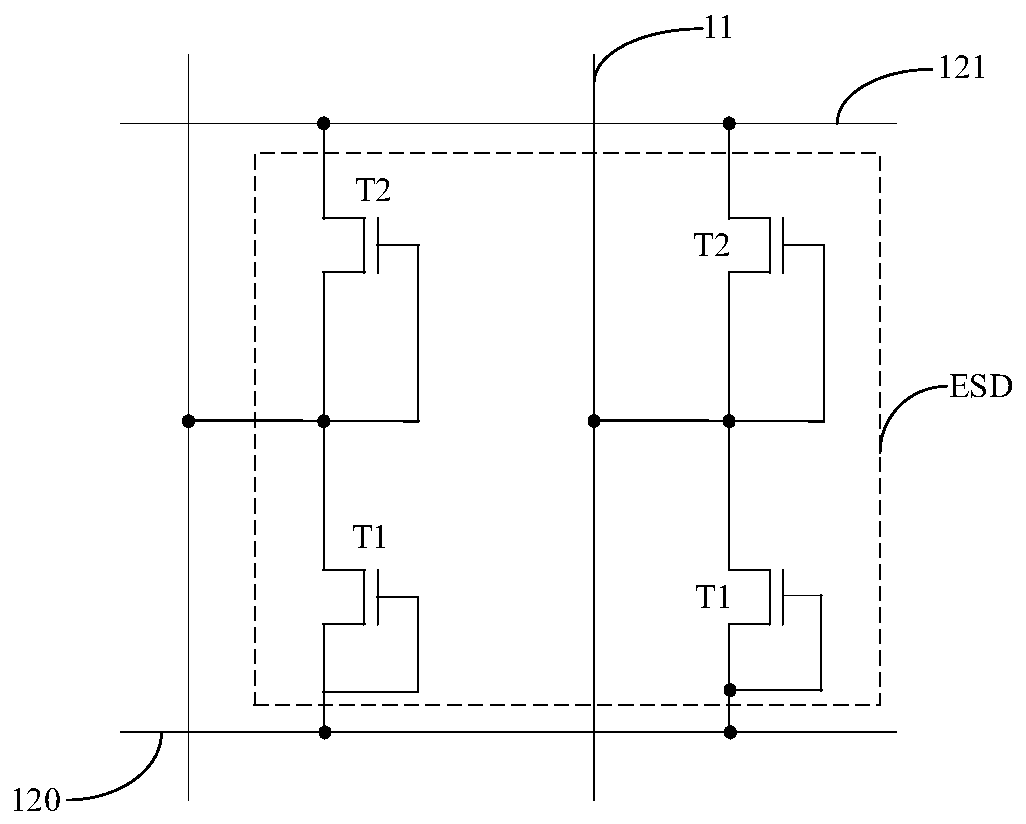

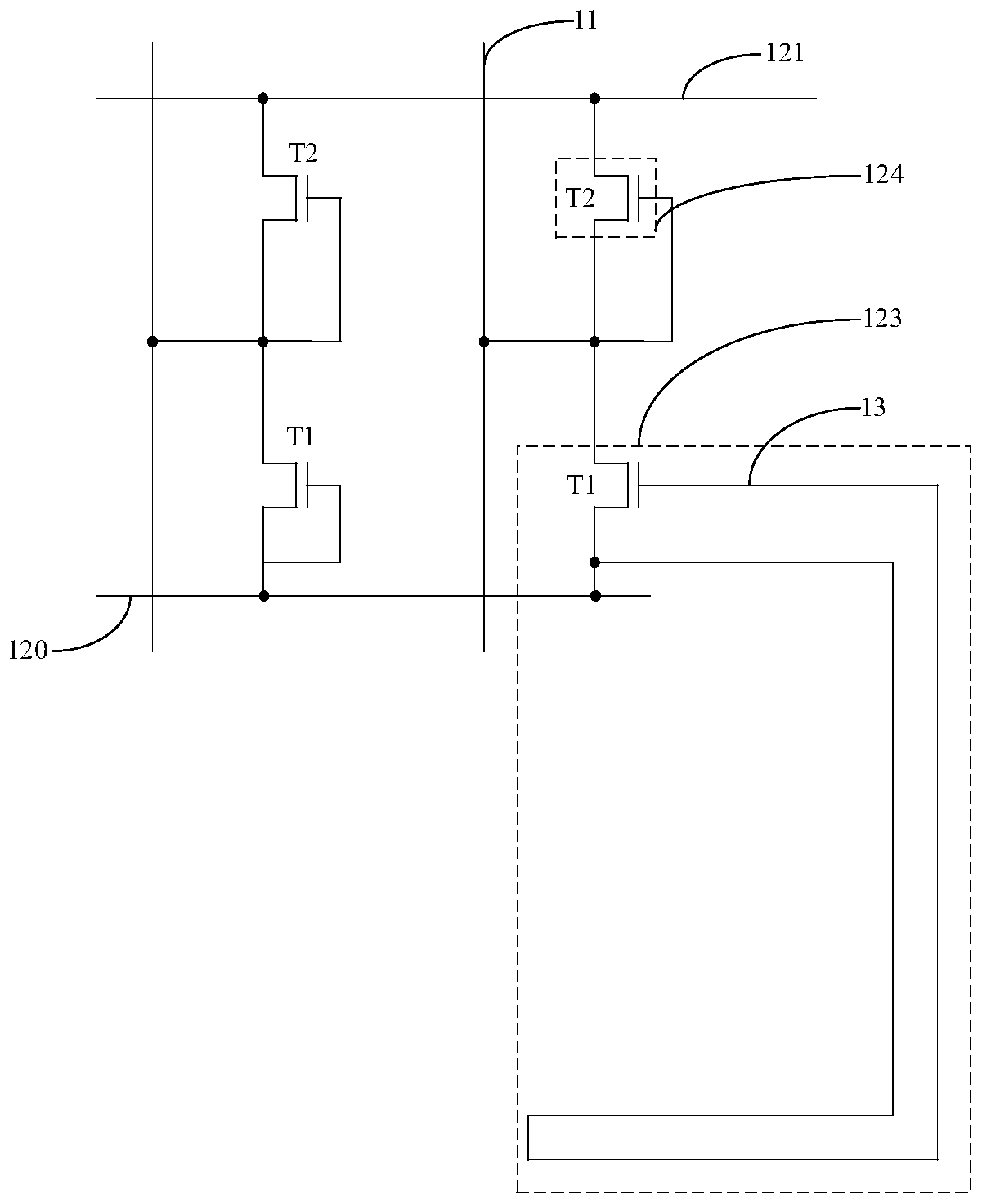

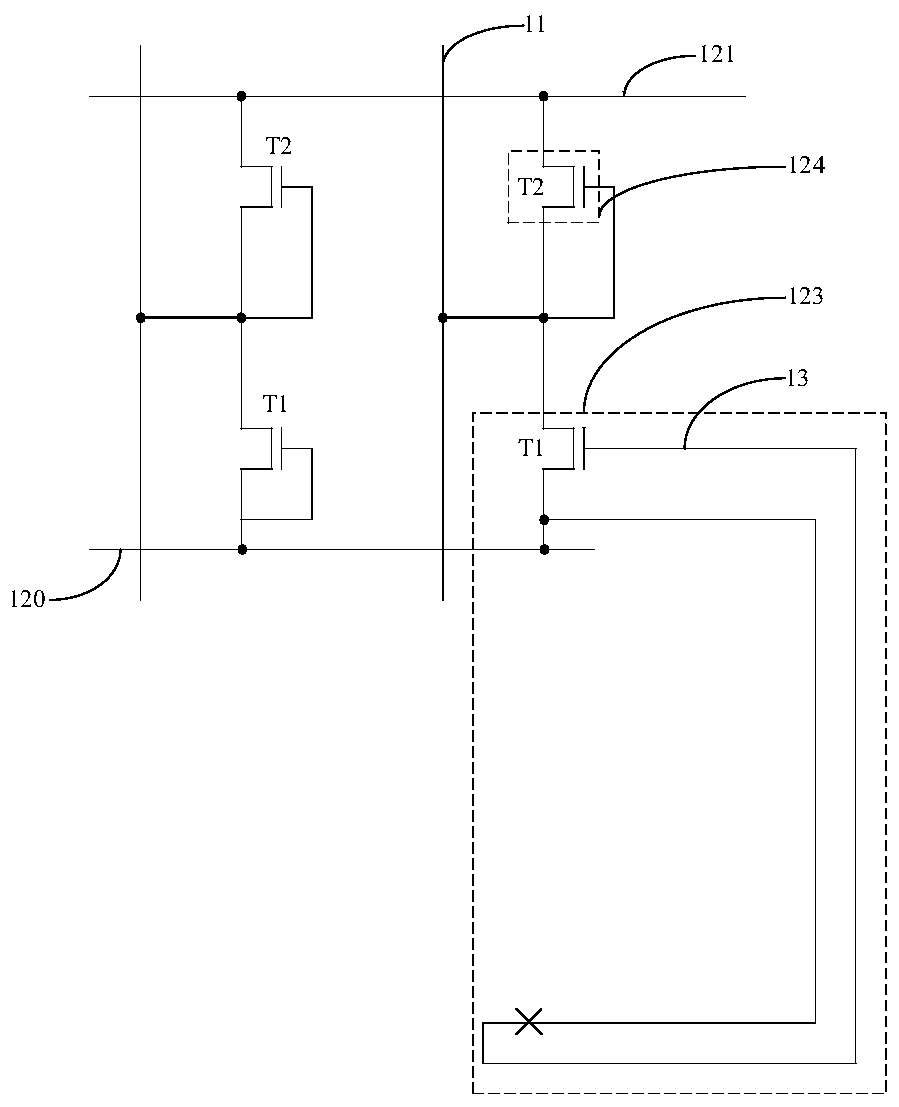

[0035] In order to further illustrate the display substrate provided by the embodiments of the present invention, the manufacturing method thereof, the crack detection method, and the display device, a detailed description will be given below in conjunction with the accompanying drawings.

[0036] In the related art, when making an organic light emitting diode display, generally, a display motherboard is fabricated first, and then the display motherboard is cut to form a single display substrate. The single display substrate can also be called a cell unit. In order to ensure The reliability of the display substrate. After the display substrate is cut and formed, the display substrate will be tested for lighting. In addition to testing whether the display substrate can achieve normal display functions, the lighting test can also detect whether there are cracks in the edge area of the display substrate.

[0037] More specifically, in order to perform crack detection, crack dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com