Assembly fixture for magnetic circuit structure of miniature loudspeaker

A technology for micro-speakers and assembly jigs, applied to sensors, electrical components, etc., can solve problems such as bad speakers, difficult assembly, cumbersome assembly procedures, etc., and achieve the effect of reducing the risk of defects and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The jig for assembling the magnetic return structure of the micro-speaker according to the embodiment of the present invention will be further described below with reference to the accompanying drawings.

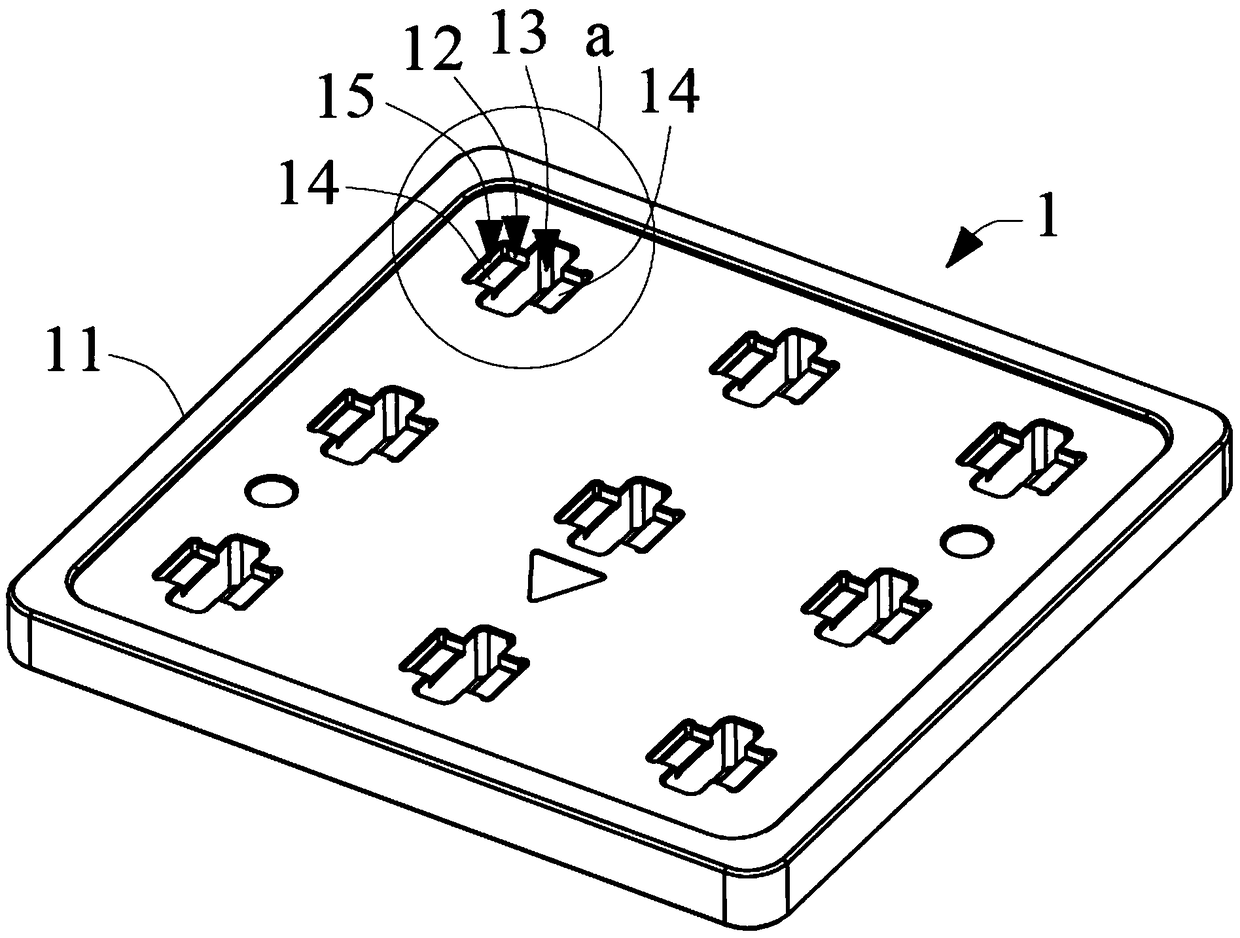

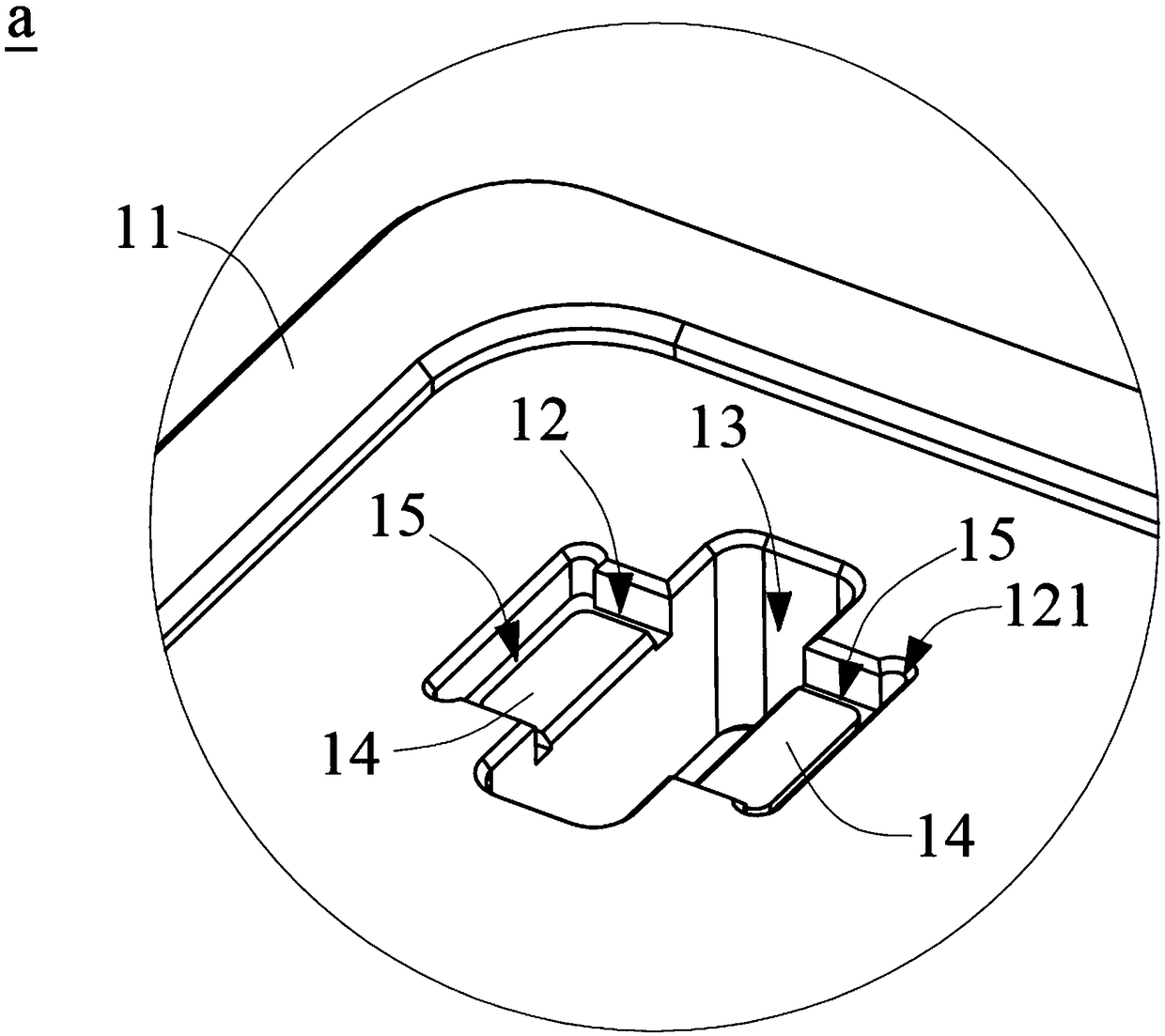

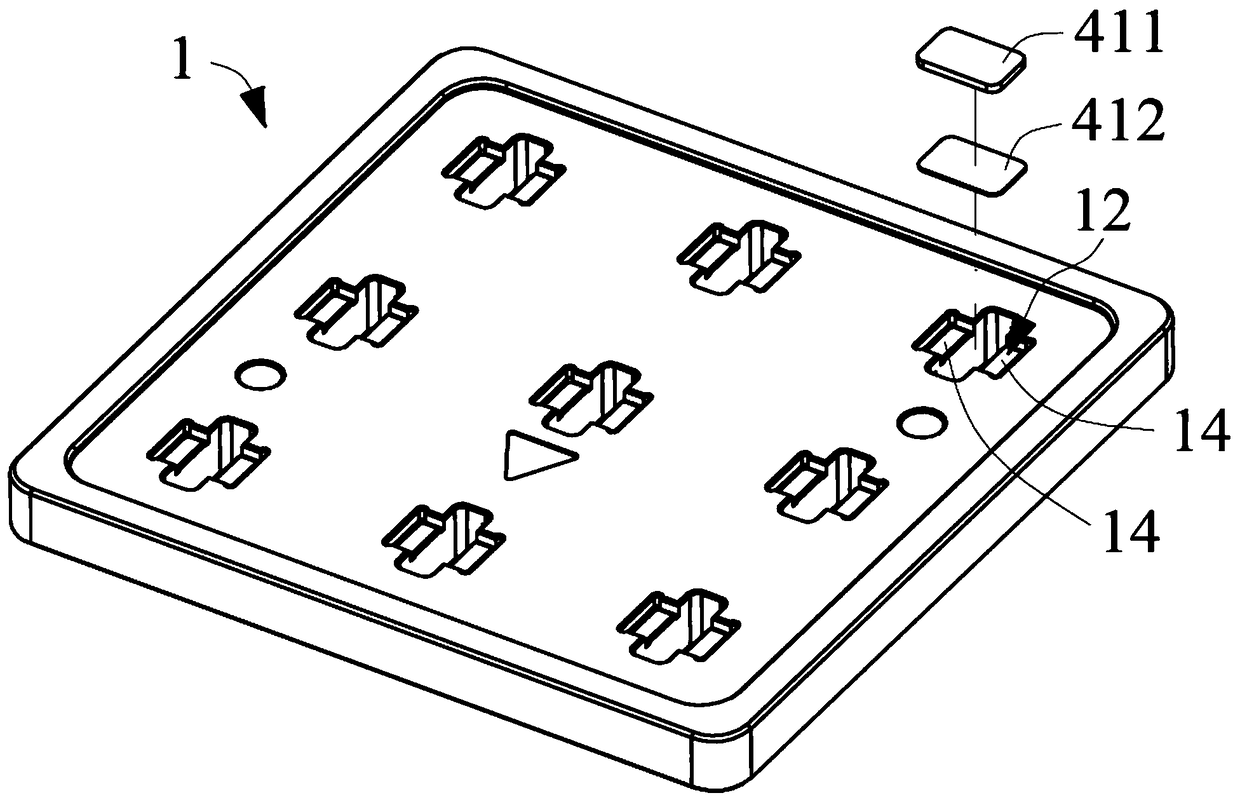

[0082] see Figure 1 to Figure 8 , as shown in the figure: the present invention provides an assembly jig for the magnetic return structure of a micro-speaker, which is used to assemble the main magnet 411 and the main magnetic plate 412 of the magnetic return structure 4, the main magnet 411 and the main magnetic plate 412 can be respectively rectangular, and described assembly jig 1 comprises: plate body 11, and described plate body 11 has a plurality of assembling grooves 12, and each assembling groove 12 has stripping hole 13 respectively, and each stripping hole 13 both sides Each bearing platform 14 is respectively provided with overflow glue groove 15 around each bearing platform 14. Each bearing platform 14 is used to carry the main magnet 411 and the main mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com