Horizontal kiering tank for kiering gauze

A bleaching and horizontal technology, applied in the field of bleaching equipment, can solve the problems of high requirements for transmission equipment, low power retention rate, and unsuitability for production lines, etc., to improve bleaching efficiency, small fluctuations in pass rate, and save production time and labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

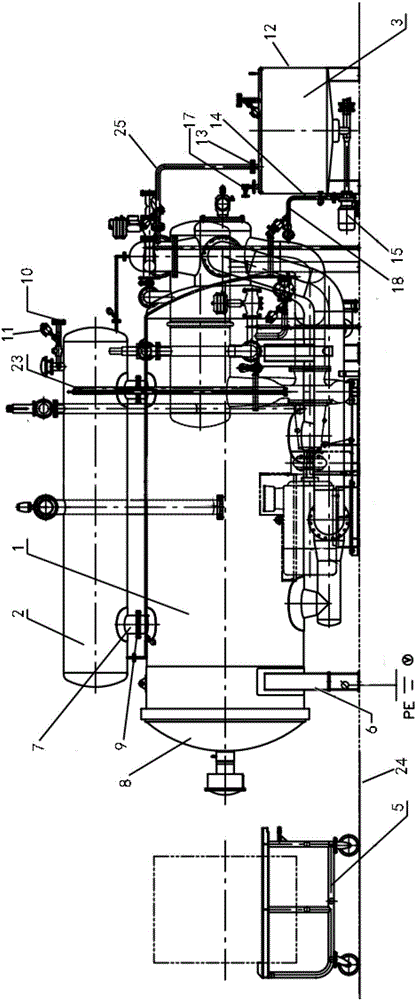

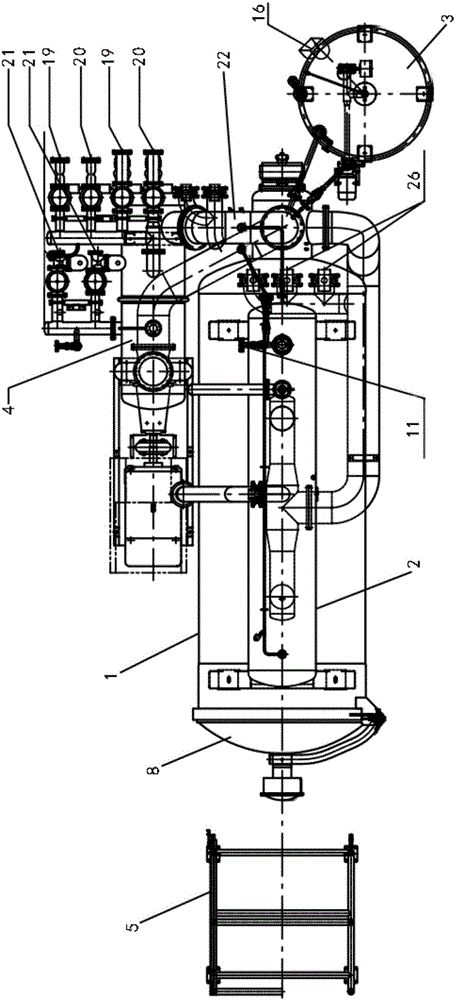

[0019] Such as Figure 1-2As shown, the bleaching tank used for gauze bleaching is composed of a main cylinder body 1, an expansion cylinder 2, a preparatory cylinder 3, a heat exchanger 4, a track trolley 5, a control panel and a water gauge device 23. The main cylinder body 1 shell, The shell of the expansion cylinder 2, the shell of the preparatory cylinder 3 and the shell of the heat exchanger 4 are all austenitic stainless steel. The main cylinder body 1 is in the shape of a cylinder and placed horizontally on the tank body support 6. This design can reduce the height of the factory building and reduce the number of operators. There is a grounding wire on the tank body support 6, which is used to prevent safety accidents caused by tank body leakage during use. The top of the main cylinder 1 is connected to the expansion cylinder 2 through the steam pipeline 7, and the upper side of the main cylinder 1 in the axial direction is the cylinder door 8, which is hinged with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com