Tool for CNC tool grinder

A tool grinding machine and tool technology, which is applied in the direction of grinding bed, manufacturing tools, grinding skateboards, etc., can solve the problems of damage and difficult cleaning, and achieve the effects of avoiding damage, facilitating grinding processing, and increasing processing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

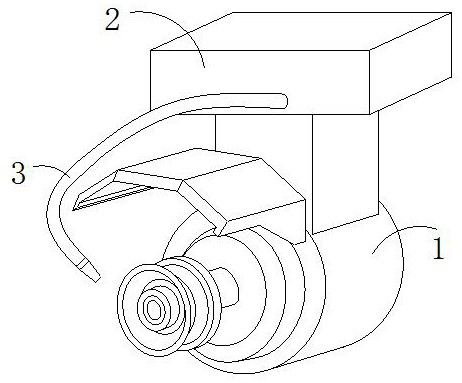

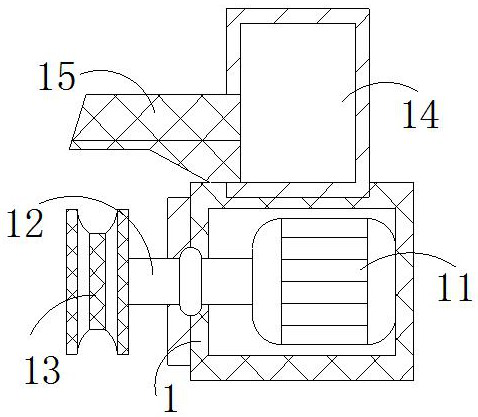

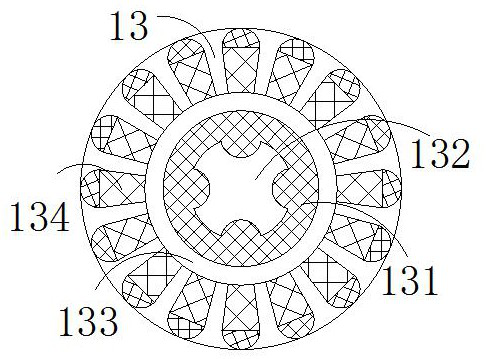

[0029] The invention provides a tool for CNC tool grinder, the structure of which includes a positioning box 1, a fixing block 2, and a cooling pipe 3, the bottom of the fixing block 2 is welded to the top of the positioning box 1, and one end of the cooling pipe 3 is embedded in a fixed On the front side of the block 2, the positioning box 1 includes a driving machine 11, a rotating shaft 12, a grinder tool 13, an isolation chamber 14, and a baffle plate 15, and the driving machine 11 is cooperatingly installed inside the positioning box 1, and the rotating shaft 12 runs through the positioning box 1. The left wall is connected to the driving machine 11. The grinder tool 13 is nested on the outer surface of the left end of the rotating shaft 12. The isolation cavity 14 is embedded in the upper interior of the positioning box 1. The right side of the baffle plate 15 is embedded in the isolation cavity. The left wall of 14 is located directly above the grinder cutter 13. The dia...

Embodiment 2

[0035]The invention provides a tool for CNC tool grinder, the structure of which includes a positioning box 1, a fixing block 2, and a cooling pipe 3, the bottom of the fixing block 2 is welded to the top of the positioning box 1, and one end of the cooling pipe 3 is embedded in a fixed On the front side of the block 2, the positioning box 1 includes a driving machine 11, a rotating shaft 12, a grinder tool 13, an isolation chamber 14, and a baffle plate 15, and the driving machine 11 is cooperatingly installed inside the positioning box 1, and the rotating shaft 12 runs through the positioning box 1. The left wall is connected to the driving machine 11. The grinder tool 13 is nested on the outer surface of the left end of the rotating shaft 12. The isolation cavity 14 is embedded in the upper interior of the positioning box 1. The right side of the baffle plate 15 is embedded in the isolation cavity. The left wall of 14 is located directly above the grinder cutter 13. The diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com