Negative pressure tobacco perfuming system

A tobacco flavoring and negative pressure technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low flavoring efficiency, energy consumption, poor flavoring uniformity, etc., and achieve good flavoring uniformity and high flavoring efficiency , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below through the examples and accompanying drawings, the purpose is only to better understand the content of the present invention, but not to limit the present invention.

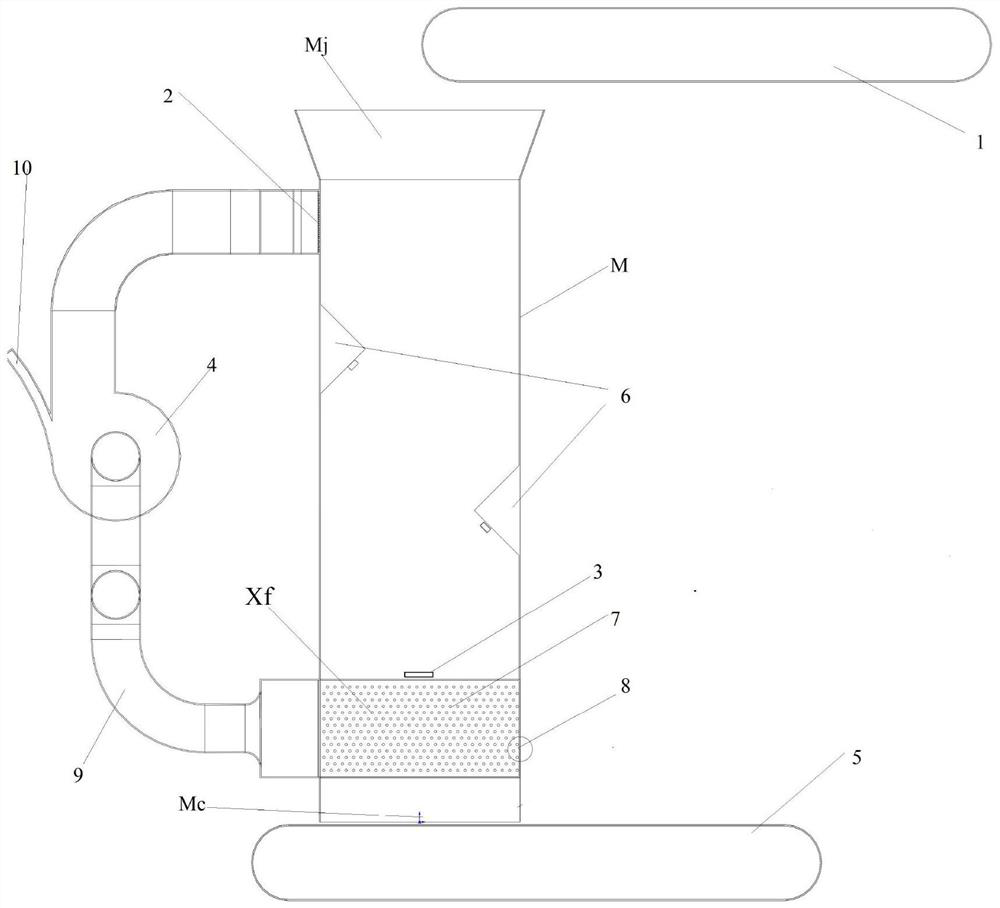

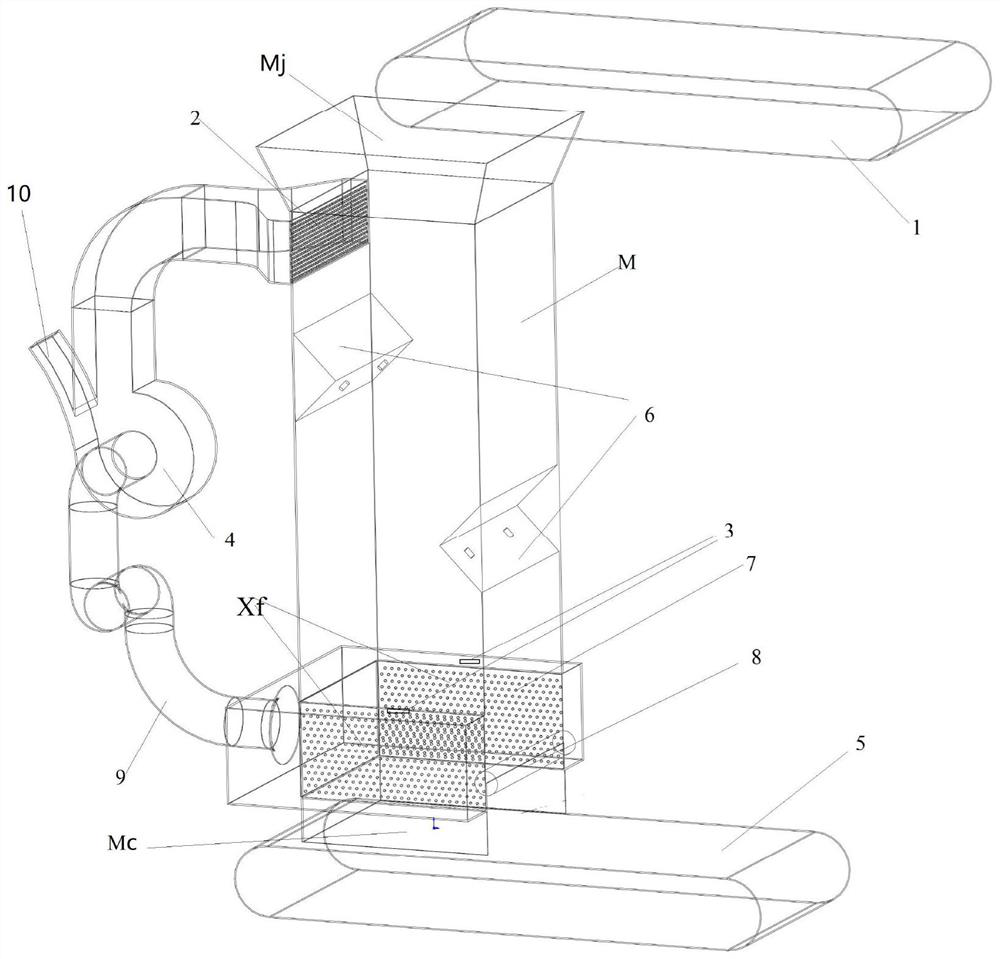

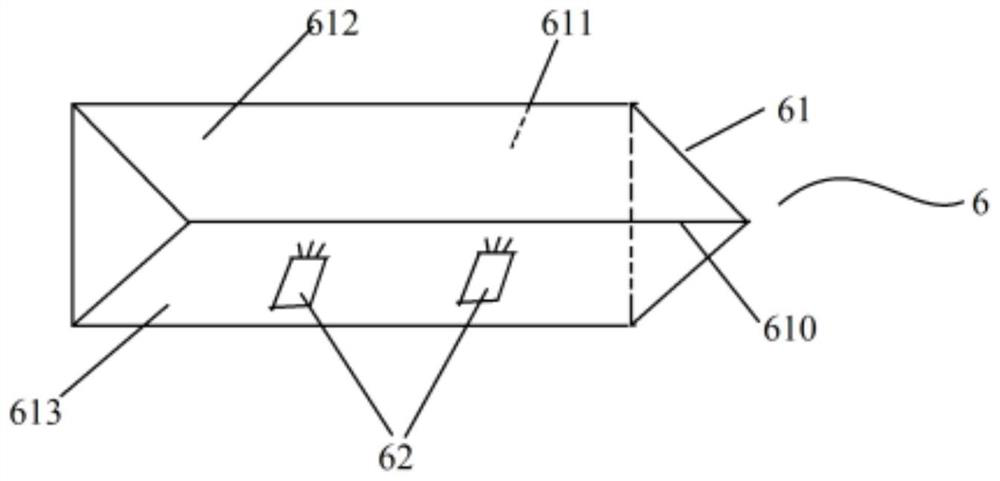

[0029] Such as figure 1 and figure 2 As shown, a negative pressure tobacco flavoring system, which includes a vertically placed cylindrical feeding tube M with a rectangular cross-section, the upper part of the charging tube M is the inlet Mj, and the bottom is the outlet Mc; There is an air suction port Xf on the wall of the upper part of the discharge port Mc of the feeding cylinder M, and the mouth of the air suction port Xf is provided with a filter screen 7, and the air suction port Xf is communicated with the circulating fan 4 through the air return pipe 9; wherein The mesh size of filter screen 7 can not pass through to guarantee shredded tobacco or tobacco leaf, and only dust can pass through. The air suction port Xf is arranged on the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com