Shoe polisher for safety shoes

A technology for a shoe polisher and labor insurance shoes, which is applied in the cleaning, application, household appliances and other directions of boots and shoes, can solve the problems that it is difficult to wipe the surface of shoes without dead corners, cannot meet the needs of use, etc., and achieves the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

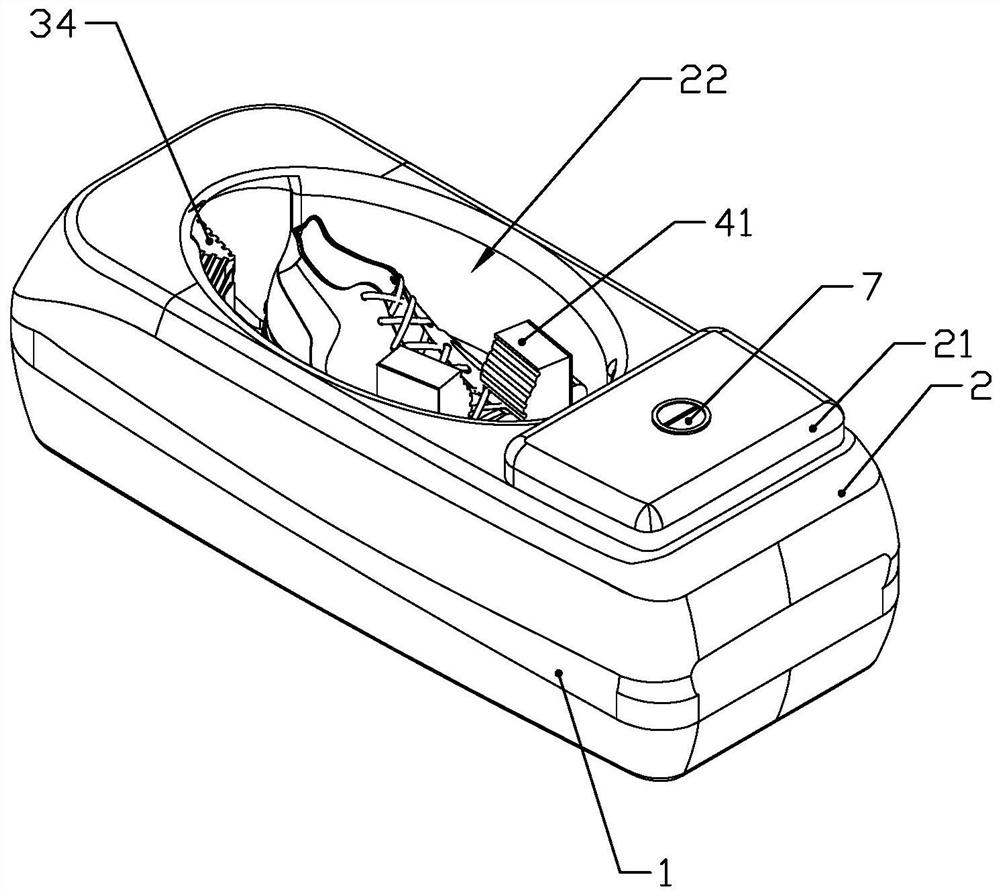

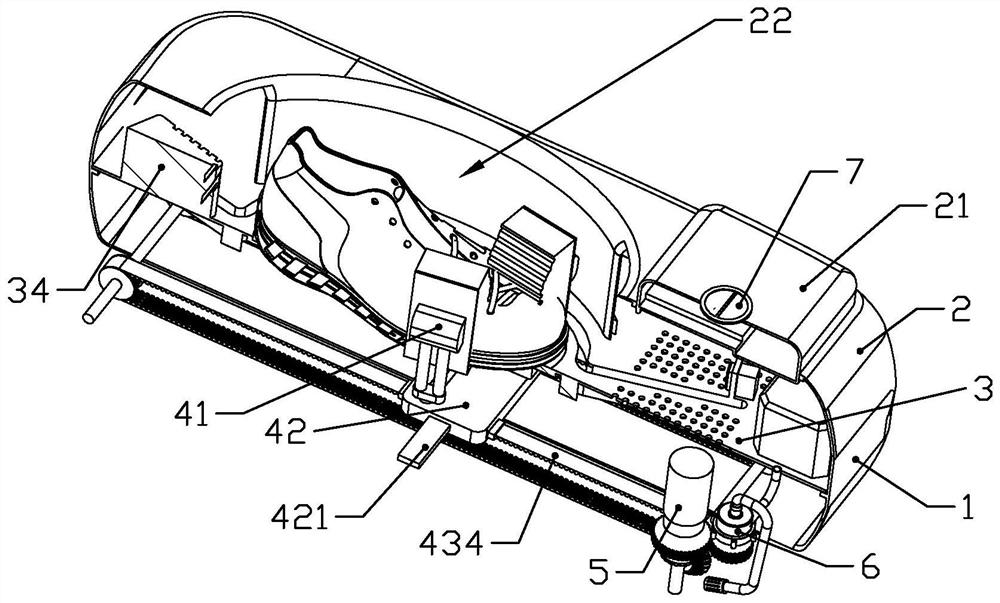

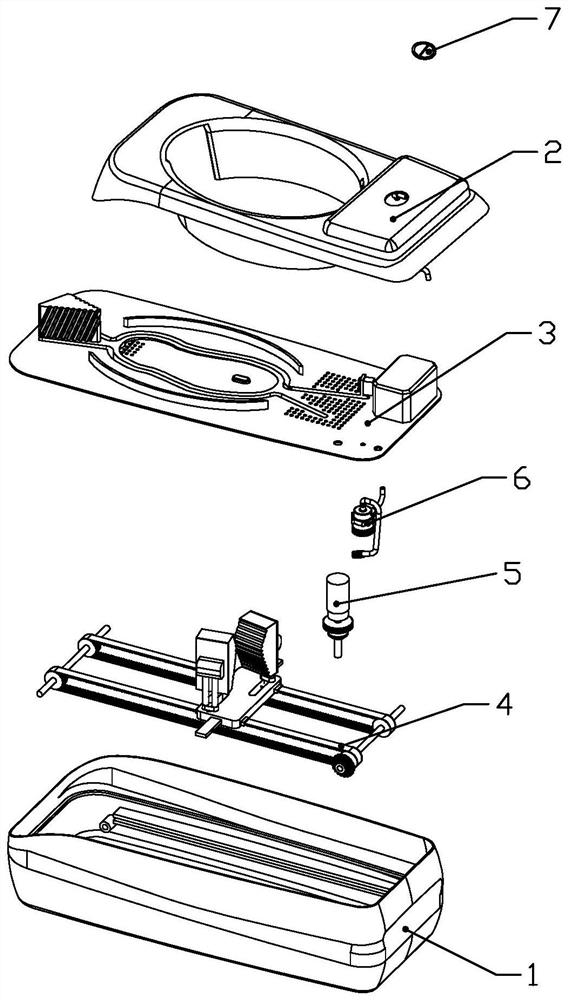

[0040] according to 1 to 9 As shown, the shoe polisher for labor insurance shoes in this embodiment includes a lower housing 1, an upper cover 2 fixedly connected to the upper end of the lower housing 1, and a shoe bearing plate 3 fixedly connected to the lower housing 1. The shoe bearing plate 3 is horizontally arranged in the middle of the lower shell 1; The upper end of the shoe bearing plate 3 is formed with two guide rails 33 penetrating the shoe bearing plate 3; The guide rails 33 are arranged in parallel along the outer contour of the sole; The guide rails 33 are respectively slidably connected with brushing parts 41 for brushing shoe uppers.

[0041] A support ring 11 extending to the center is formed in the middle of the inner wall of the lower shell 1; The shoe bearing plate 3 is fixedly connected to the upper end of the support ring 11.

[0042] According to the actual situation (about men and women), the outer contour of the sole is different, and the closest ellipse i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com