A kind of knife handle water transfer printing device for knife making

A water transfer printing and knife handle technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of high buoyancy of the knife handle, affecting the effect of the knife handle, and labor consumption, so as to ensure the effect, save labor, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

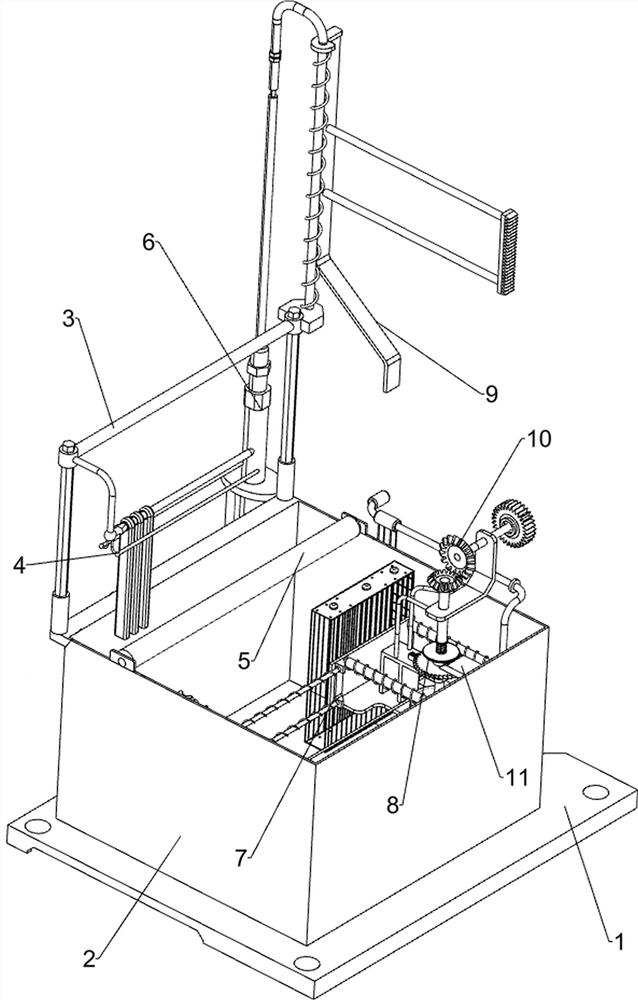

[0027] A knife handle water transfer device for knife making, such as Figure 1-4 As shown, it includes a base 1, a liquid storage frame 2, a first sliding frame 3, a limit rod 4 and a material separator 5. The top of the base 1 is connected with a liquid storage frame 2, and the top of the liquid storage frame 2 slides on the left side. A first sliding frame 3 is connected, the left and right sides of the bottom of the first sliding frame 3 are connected with limit rods 4, the top left side of the liquid storage frame 2 is connected with a material separator 5, and also includes a lifting assembly 6, a collecting assembly 7 and a pusher. There is a lifting assembly 6 between the base 1 and the first sliding frame 3 , a collecting assembly 7 is disposed in the liquid storage frame 2 , and a pushing assembly 8 is disposed on the collecting assembly 7 .

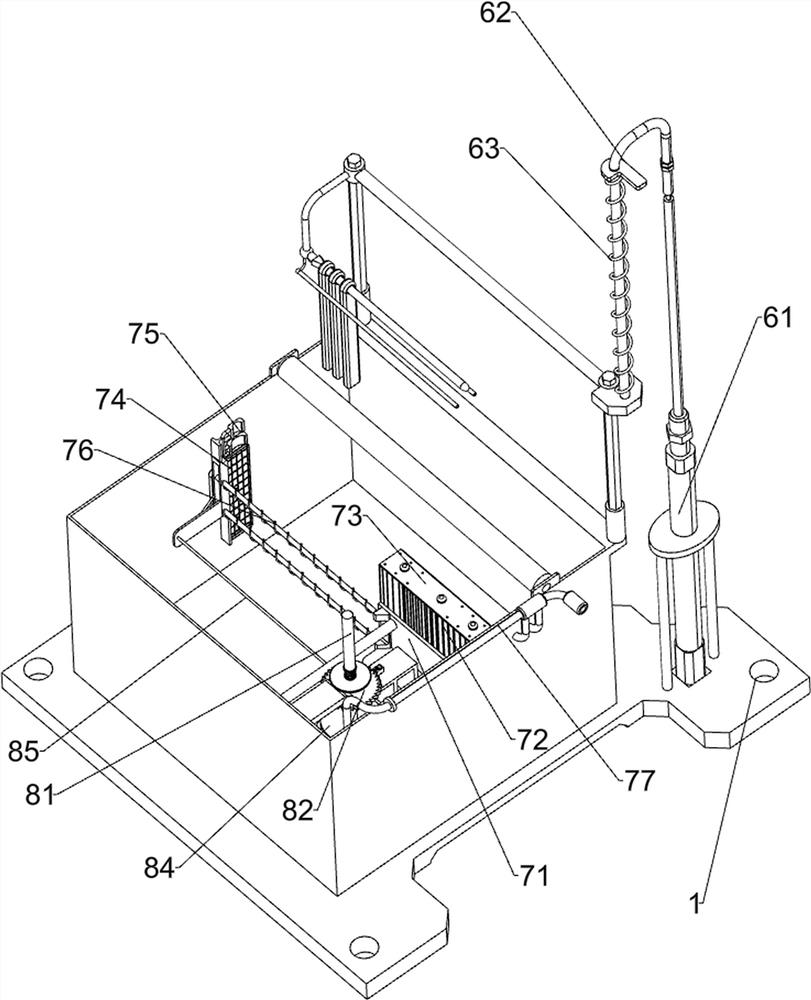

[0028] The lifting assembly 6 includes a cylinder 61, a second sliding frame 62 and a compression spring 63. A cylinder 61 is...

Embodiment 2

[0033] On the basis of Example 1, as image 3 As shown, it also includes a moving assembly 9, the moving assembly 9 includes a guide plate 91 and a tension spring 92, a guide plate 91 is connected to the second sliding frame 62, the guide plate 91 cooperates with the sliding rod 77, and the first mounting frame 71 A tension spring 92 is connected to the liquid storage frame 2 .

[0034]When the second sliding frame 62 moves up and down, it will drive the guide plate 91 to move up and down together. When the first sliding frame 3 moves down to the limit, the guide plate 91 also moves to contact the sliding rod 77, and the compression spring 63 is compressed. When the second sliding frame 62 continues to move downward, pull the sliding rod 77 to move to the left, the movement of the sliding rod 77 drives the first mounting frame 71 to move, and the tension spring 92 is stretched. The first mounting frame 71 is reset under the action of the spring 92, so that there is no need to...

Embodiment 3

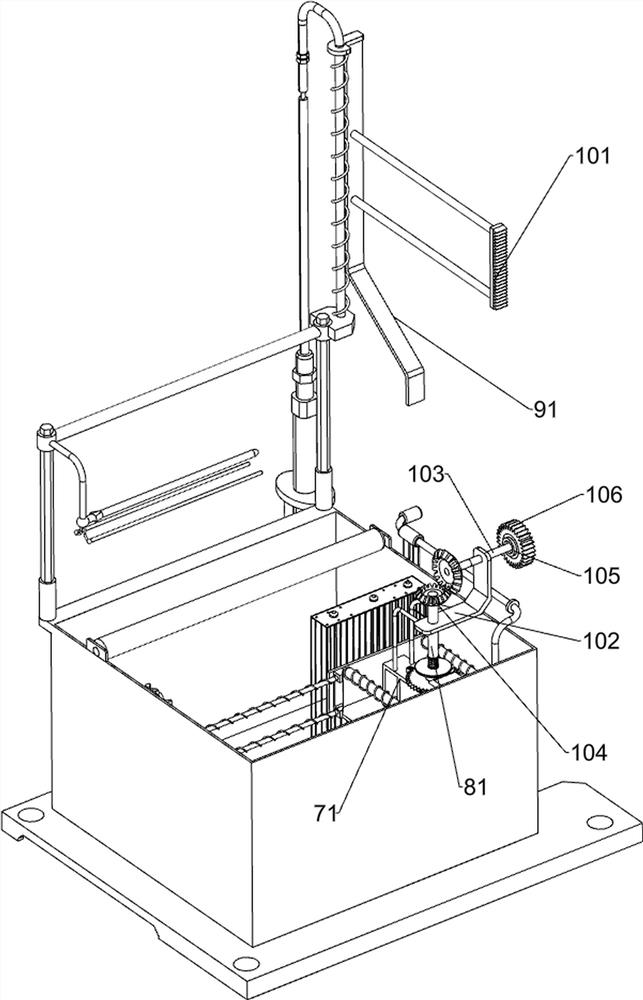

[0036] On the basis of Example 2, as Figure 5 As shown, it also includes a rotating assembly 10. The rotating assembly 10 includes a drive rack 101, a second mounting frame 102, a rotating shaft 103, a bevel gear 104, a one-way clutch 105 and a drive gear 106. The right side of the guide plate 91 is connected with a drive Rack 101, a second mounting frame 102 is connected to the first mounting frame 71, a rotating shaft 103 is rotatably connected to the second mounting frame 102, a one-way clutch 105 is connected to the rear of the rotating shaft 103, and a drive is connected to the one-way clutch 105 The gear 106, the driving rack 101 will mesh with the driving gear 106, the top of the shaft 81 and the front of the rotating shaft 103 are connected with a bevel gear 104, and the two bevel gears 104 are meshed with each other.

[0037] When the guide plate 91 moves up and down, it drives the driving rack 101 to move up and down together. When the driving rack 101 moves down to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com