Full-automatic transfer printing device and method for water transfer printing process

A fully automatic, water transfer printing technology, applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of low work efficiency, fatigue, waste of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

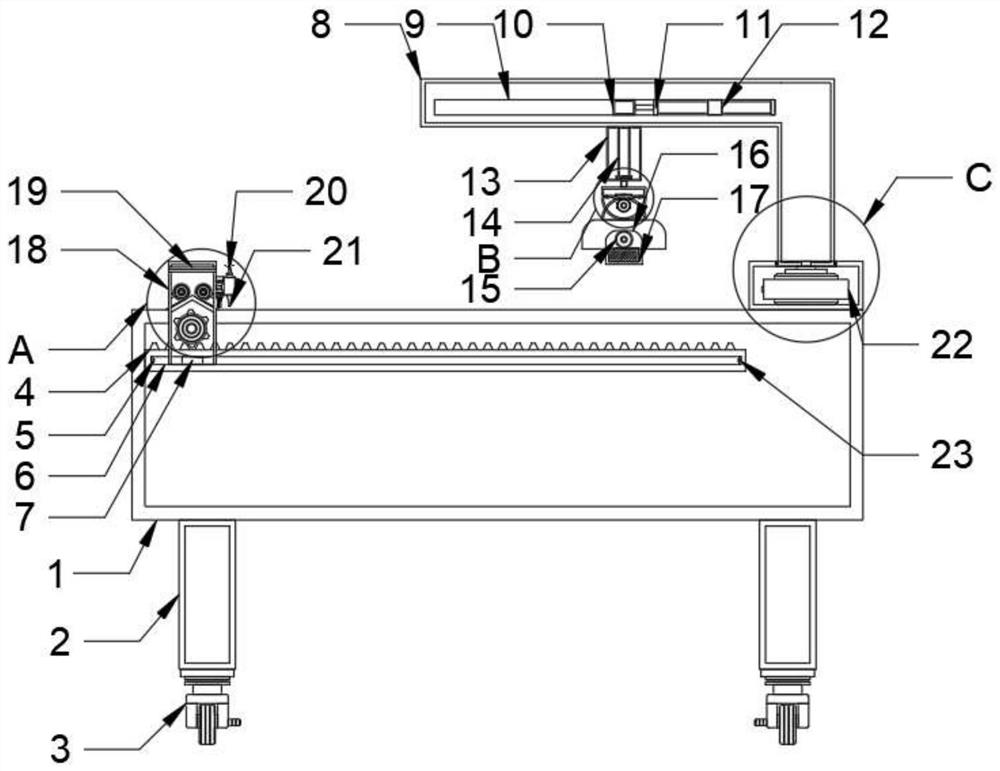

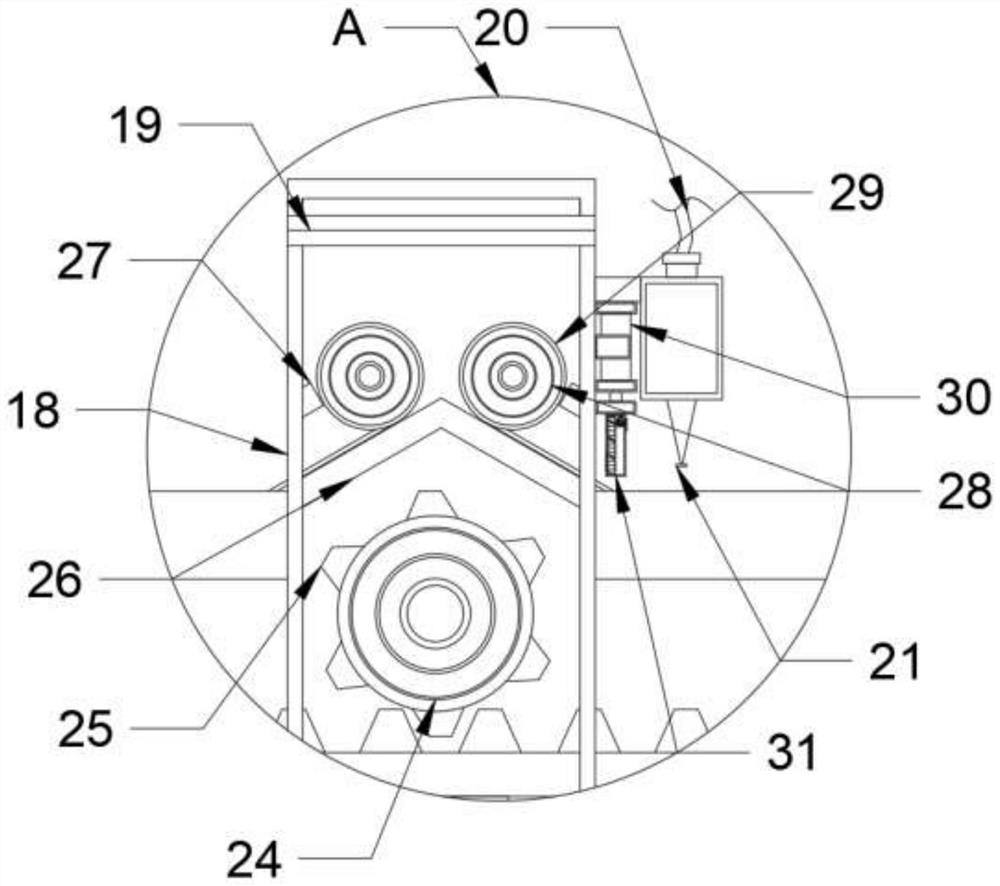

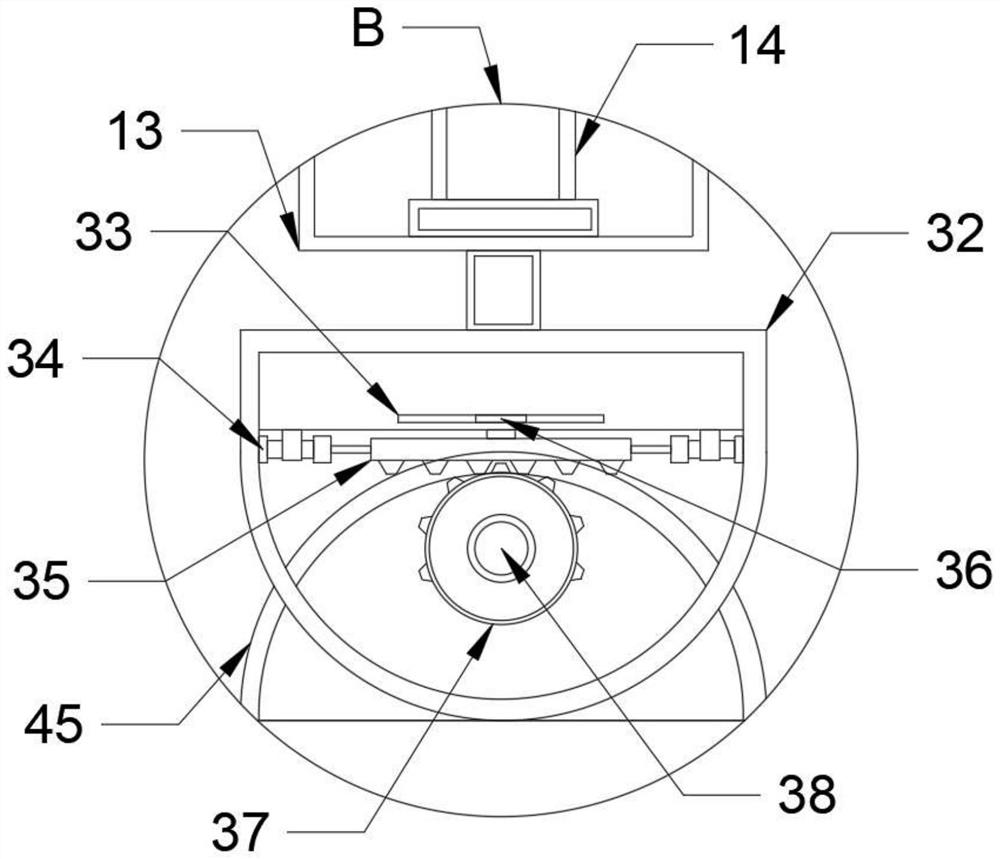

[0033] like Figure 1-Figure 8 As shown, this embodiment provides a fully automatic transfer device for water transfer process, including a water transfer box 1 , a support leg 2 , a universal wheel 3 , a first rack 4 , and a first control button 5 , the first sliding slot 6, the support frame 8, the second sliding slot 9, the slider 10, the first telescopic rod 11, the positioning block 12, the limit box 13, the second telescopic rod 14 The film laying frame 18, the limit block 19 and the second control button 23, support legs 2 are installed at the four corners of the bottom of the water transfer box 1, universal wheels 3 are installed at the bottom of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com