Waste recycling and cutting equipment for non-woven fabric processing

A technology of waste recycling and cutting equipment, which is applied in metal processing, textile material cutting, and thin material processing, etc. It can solve the problems of high economic cost, cumbersome work steps, and slow work efficiency, and achieve non-woven fabrics that are accurate and easy to use , Prevent the effect of pleats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

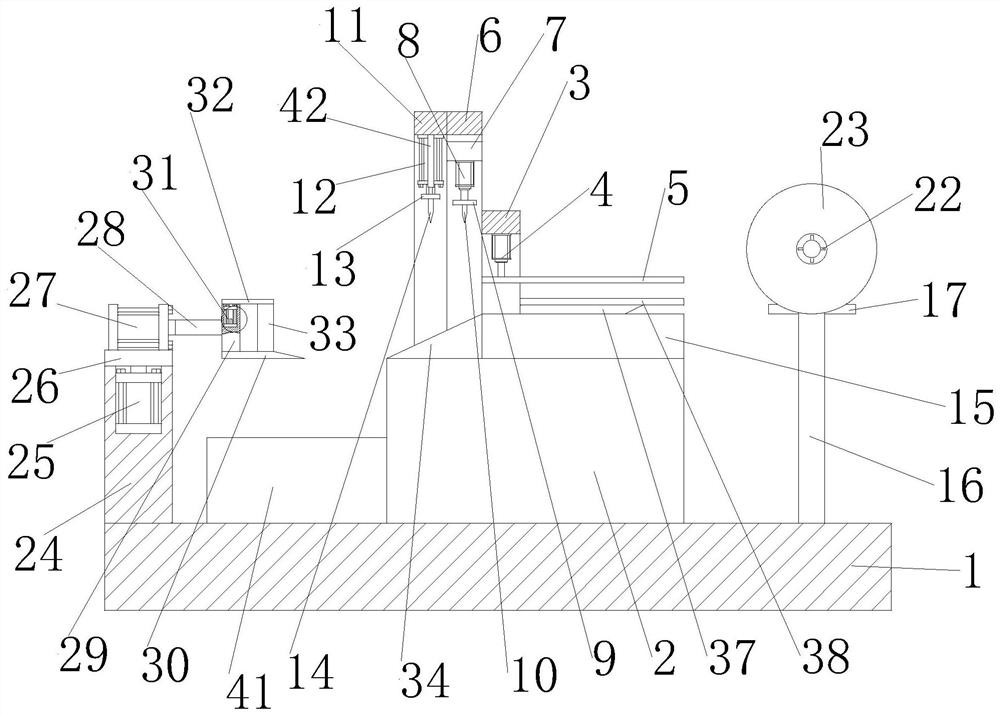

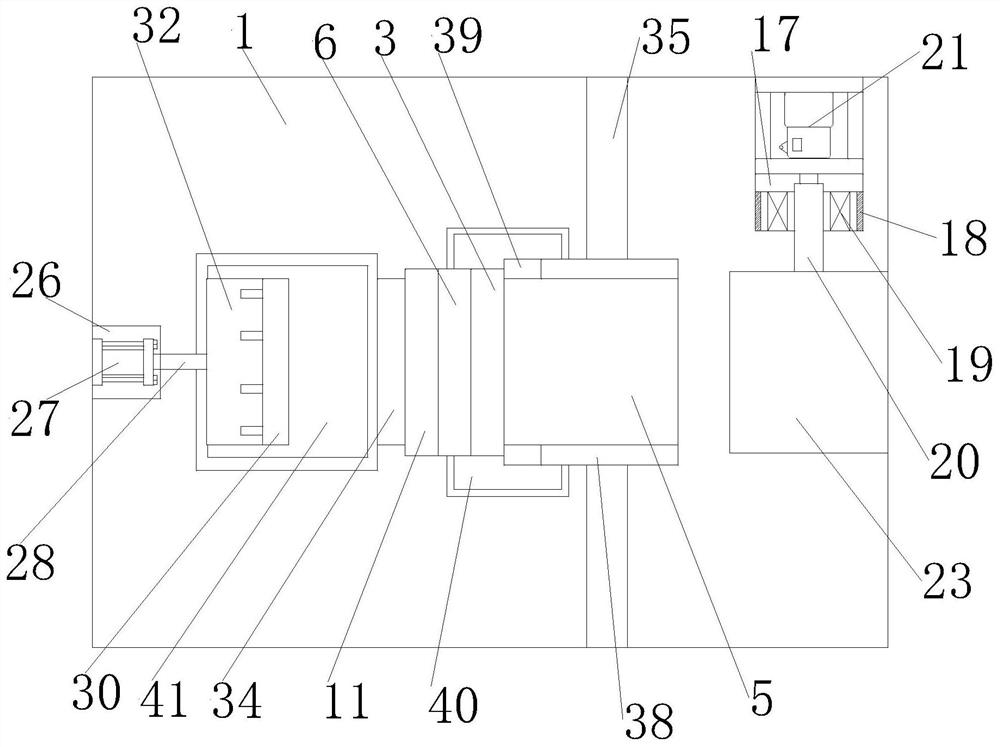

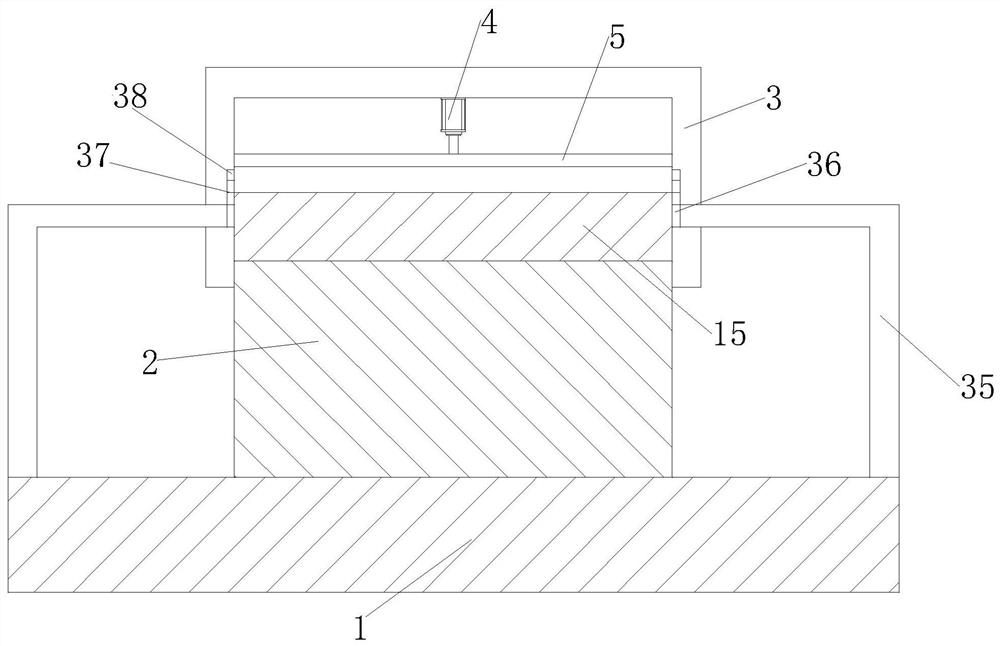

[0032] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-9As shown, a waste recycling and cutting equipment for non-woven fabric processing includes a mounting table 1, on which a stretching and equal-sized cutting unit is installed, and on the mounting table 1, it is located before and after the stretching and equal-sized cutting unit A pair of edge cutting waste collection mechanisms with the same structure are installed on both sides; the stretching equal-sized cutting unit includes: a stretching mechanism and a carrying coil cutting mechanism; the carrying coil cutting mechanism includes: a carrying platform 2, a second One installation frame 3, the first hydraulic cylinder 4, the pressure plate 5, the second installation frame 6, the direct pin screw module 7, the second hydraulic cylinder 8, the connecting plate 9, the transverse cutter 10, the third installation frame 11, the fourth Electric push rod 12, first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com