Method for avoiding folds on two side edges of edge-seam-free underwear

A technology for seamless underwear and underwear, applied in the field of pre-dyeing and dyeing, can solve the problems of lowering the grade of seamless underwear, affecting the appearance of seamless underwear products, etc., and achieve the effect of preventing creases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 Men's boxer pants

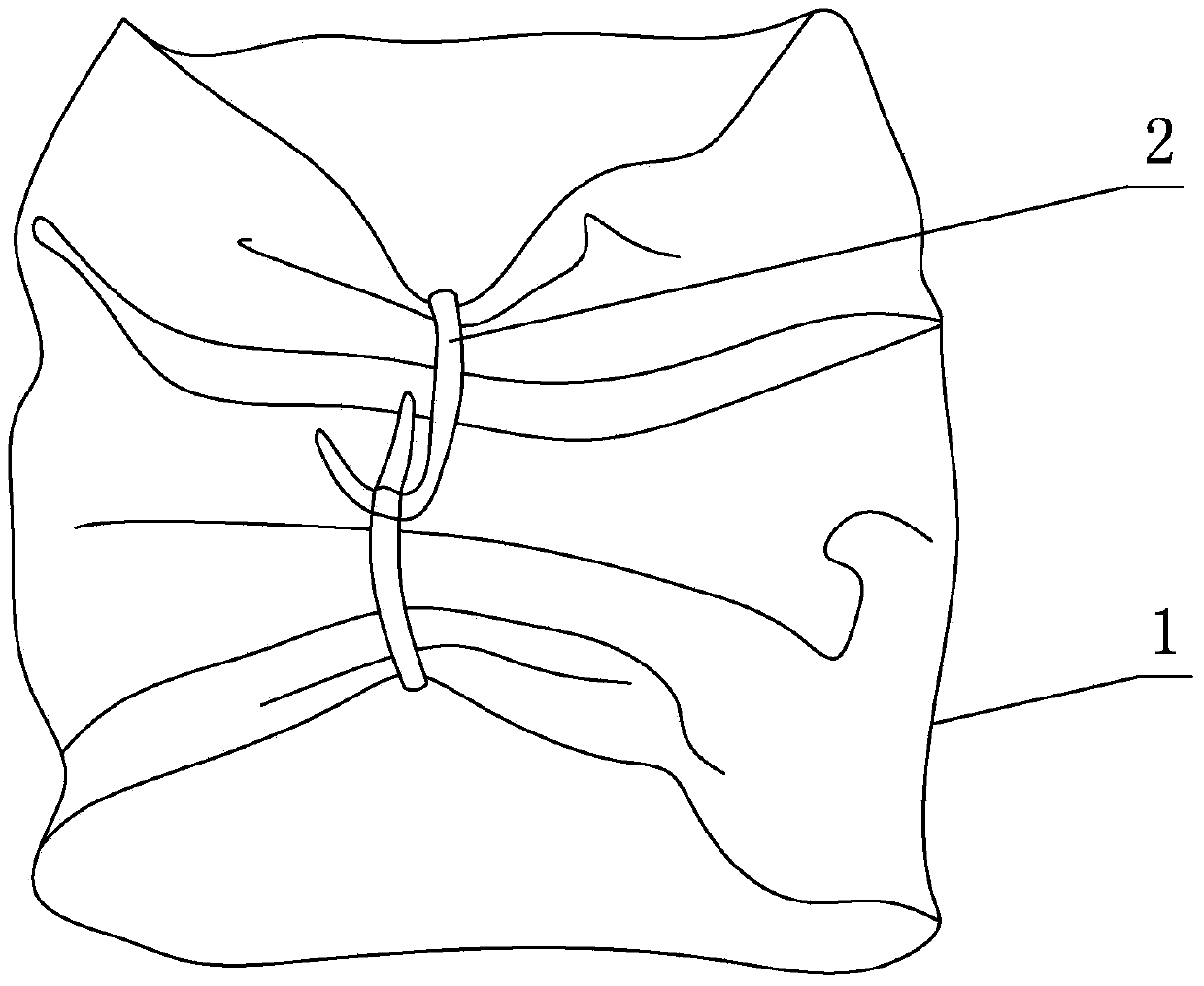

[0056] Hang and place, transfer, and steam after weaving off the machine. The length of the boxer trousers is 28cm, and the elastic band 2 with a length of 35cm is taken. figure 1 In the state shown, string the ribbons 2 and tie them into knots, and then go to the garment dyeing vat for dyeing. After knotting, the length of the seamless underwear at the position covered by the belt 2 is 14-18cm.

Embodiment 2

[0057] Example 2 tube top

[0058] Hang and place, transfer, and steam after weaving off the machine. figure 1 In the state shown, string the ribbons 2 and tie them into knots, and then go to the garment dyeing vat for dyeing. After knotting, the length of the seamless underwear at the position covered by the belt 2 is 15-19cm.

Embodiment 3

[0059] Embodiment 3 women's vest

[0060] Hang and place, transfer, and steam after weaving off the machine. figure 1 In the state shown, string the ribbons 2 and tie them into knots, and then go to the garment dyeing vat for dyeing. After knotting, the length of the seamless underwear at the position covered by the belt 2 is 29-35cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com