Image forming apparatus

A technology of inkjet recording, equipment, applied in printing etc., which can solve problems such as difficulty in uniformity of distance, degradation of image quality, etc., and achieve effects of preventing deterioration, uniformity of shape and position, and improvement of user-friendly functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

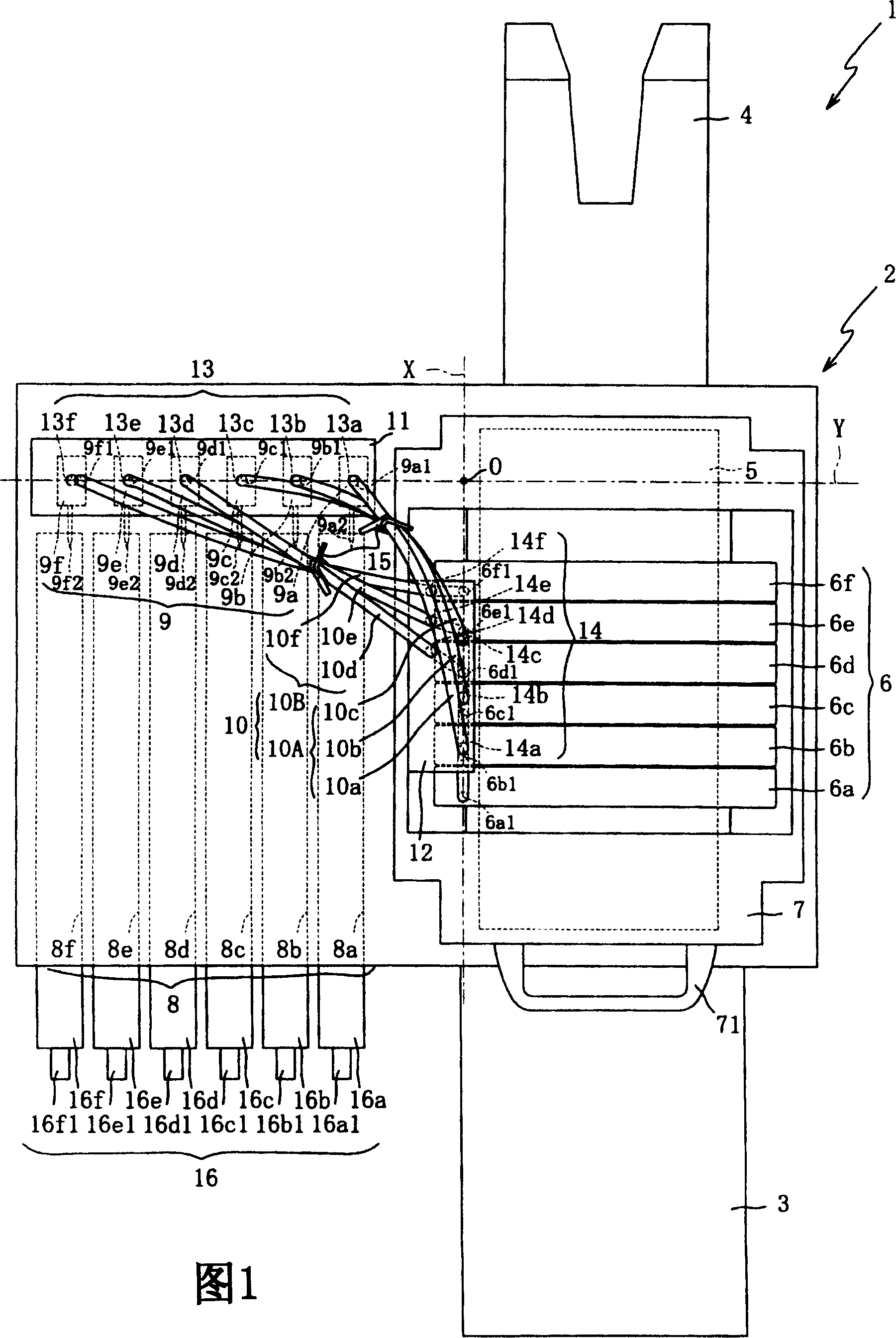

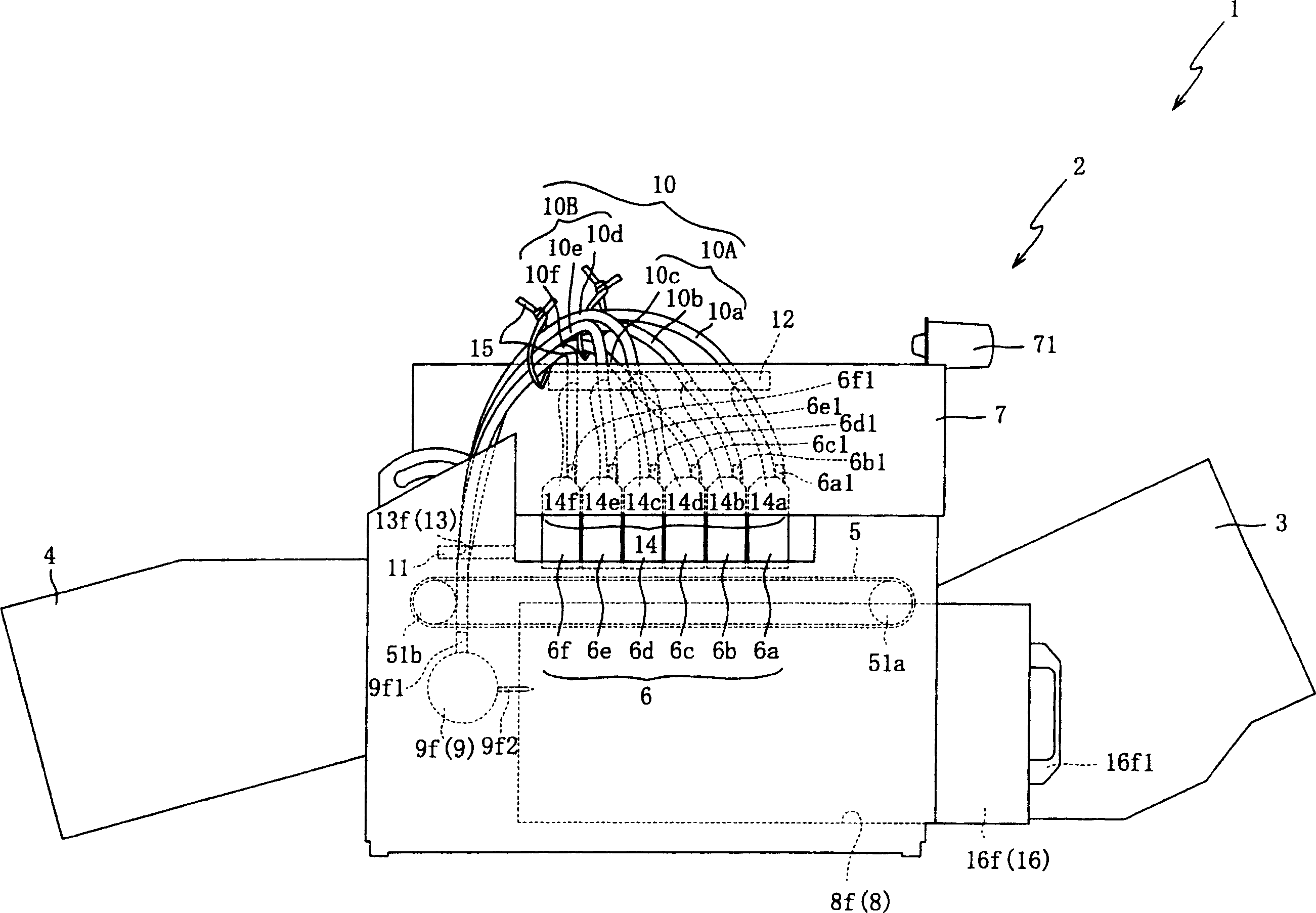

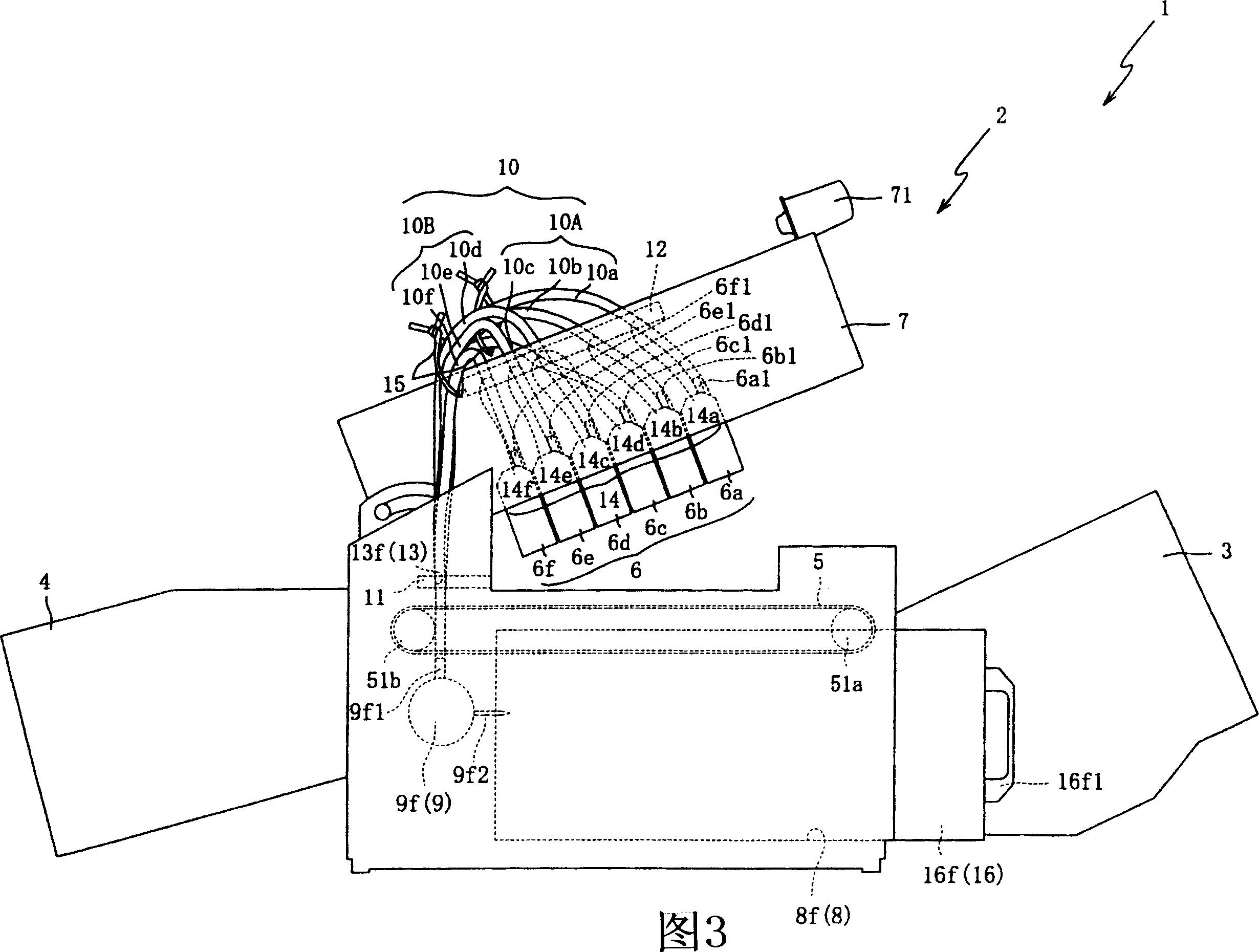

[0043] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Fig. 1 is a top view of an inkjet recording apparatus 1 according to a first embodiment of the present invention. The description will start with the general arrangement of the inkjet recording apparatus 1 with reference to FIG. 1 .

[0044] The inkjet recording apparatus 1 includes: a supply unit 3 (recording medium supply unit) for supplying a recording medium (not shown); forming an image; and a stacker 4 for storing recording media on which an image is formed by the main body 2 .

[0045] The supply unit 3 includes a tray (not shown) for accommodating a recording medium and a pickup roller (not shown) for contacting the recording medium accommodated in the tray. The supply unit 3 is designed for supplying recording media to the main body 2 when the pickup roller is actuated. A new recording medium is loaded into the supply unit 3 from the front side or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com