Negative ion formaldehyde-removing odor-removing aqueous solution and preparation method thereof

A negative ion and deionized water technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor aldehyde removal effect of aldehyde removers, avoid volatilization of formaldehyde, easy to stir evenly, and easy to stir Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

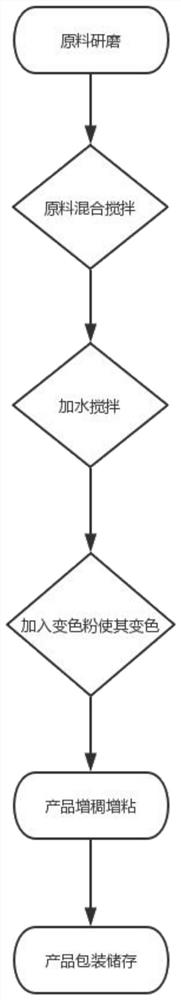

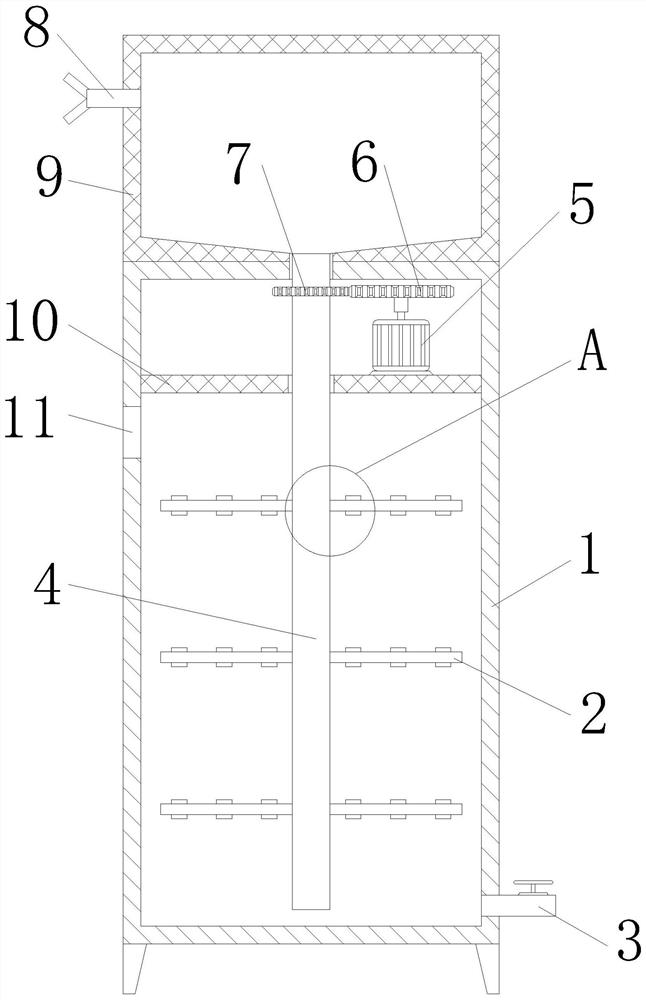

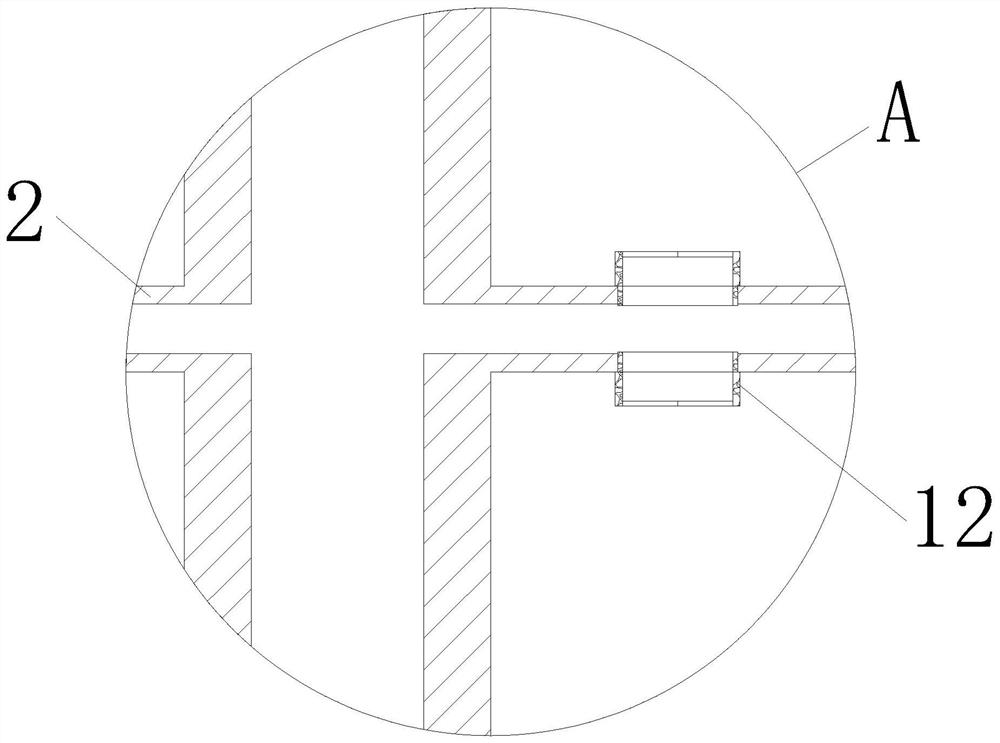

[0033] Such as Figure 1-4 As shown, the embodiment of the present invention provides a kind of negative ion aldehyde deodorizing water agent, comprising 30 parts by weight of ammonium bicarbonate, 15 parts of sepiolite, 50 parts of deionized water, 5 parts of calcium stearate, discoloration 6 parts of powder, 10 parts of thickener, 10 parts of thickener, the thickener is a cellulose thickener, the thickener is a water-based tackifying resin, and the color-changing powder is a conventional pigment, which can be prepared according to the color of the customer's interior decoration .

[0034] A kind of preparation method of negative ion aldehyde deodorizing water agent, concrete preparation method is as follows:

[0035] S1. Weigh ammonium bicarbonate, sepiolite, and calcium stearate in proportion, and grind them separately. The ground powder is sieved, and weighed after sieving to ensure that the proportions are consistent;

[0036] S2. Put the ground and sieved raw materials...

Embodiment 2

[0045] A negative ion formaldehyde-removing and deodorizing water agent, comprising 40 parts by weight of ammonium bicarbonate, 18 parts of sepiolite, 60 parts of deionized water, 7 parts of calcium stearate, 8 parts of discoloration powder, and 13 parts of thickener 15 parts of viscosifying agent, the thickener is cellulose thickener, the viscosifying agent is water-based tackifying resin, and the color changing powder is conventional pigment, which can be specifically prepared according to the color of the customer's interior decoration.

[0046] Ammonium bicarbonate, sepiolite, calcium stearate grinding and sieving standard is 1850 mesh in S1, stirring environment in S2 is 23 degrees Celsius, stirring time in S3 and S4 is 2 hours, and stirring temperature is 18 degrees Celsius, in S6 The vacuum storage temperature is 23 degrees Celsius. Add thickener and viscosifier in S5 and stop stirring when the product viscosity is 4200cP.

[0047] Product data sheet of embodiment one ...

Embodiment 3

[0050] Thickeners can be replaced by acrylic thickeners, associative polyurethane thickeners and inorganic thickeners. Polyacrylic thickeners have strong thickening and good leveling properties, and are biologically stable Good resistance, but sensitive to pH value and poor water resistance; the association structure of associative polyurethane thickener is destroyed under the action of shear force, and the viscosity decreases. When the shear force disappears, the viscosity can be restored. It can prevent the sagging phenomenon in the construction process. And its viscosity recovery has a certain hysteresis, which is conducive to the leveling of the coating film. The relative molecular mass (thousands to tens of thousands) of polyurethane thickeners is much lower than the relative molecular mass (hundreds of thousands to millions) of the first two types of thickeners, and will not promote splashing. Polyurethane thickener molecules have both hydrophilic and hydrophobic groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com