A method for optimizing the semi-clutch tip-out working condition of a manual transmission vehicle

A half-clutch, gear-shifting technology, applied to components with teeth, transmission control, belts/chains/gears, etc., can solve problems such as speed drop, reduce impact, optimize driving conditions, and optimize results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

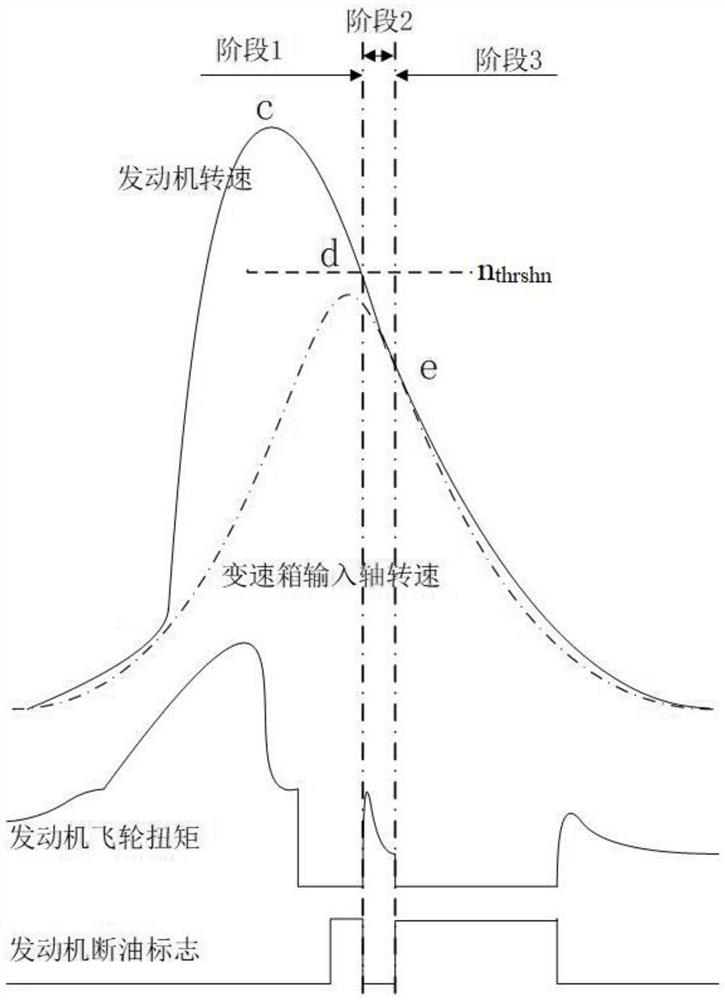

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

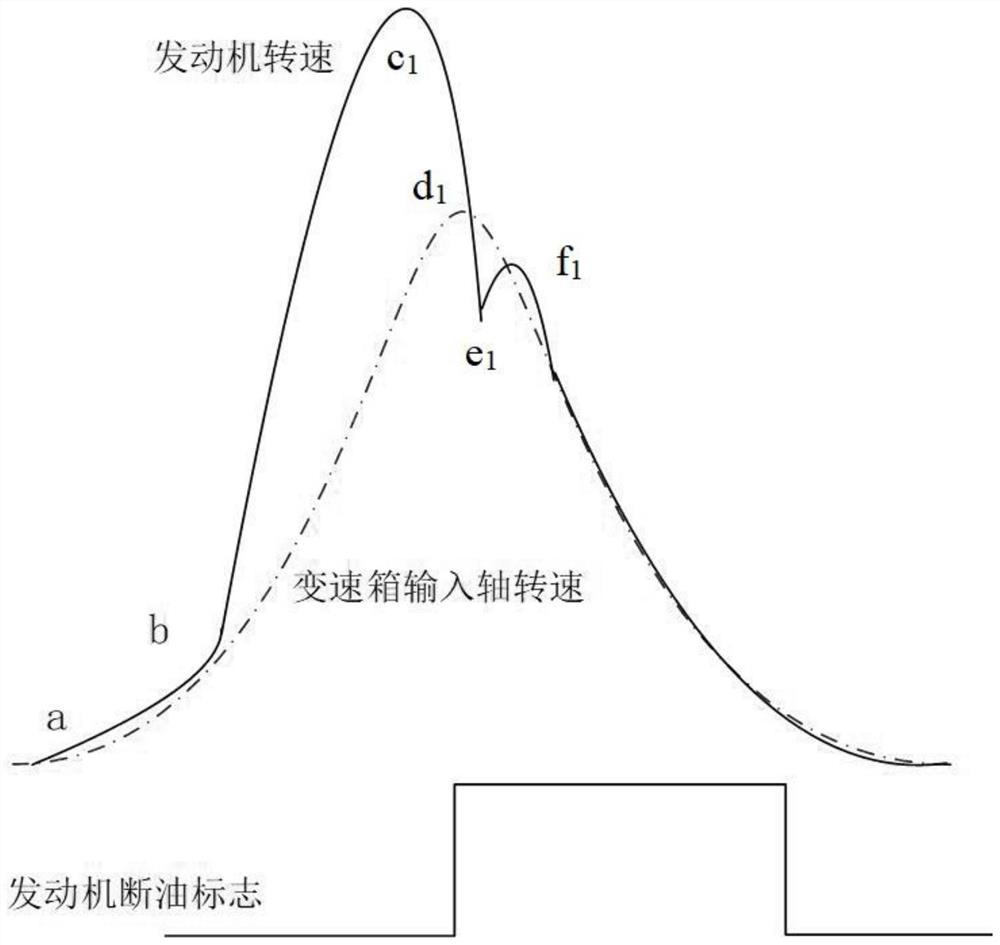

[0038] The optimization method provided in this embodiment is a control method aimed at reducing the shock during the synchronization process of the flywheels at both ends of the clutch under the half-clutch tip-out working condition, thereby optimizing the drivability.

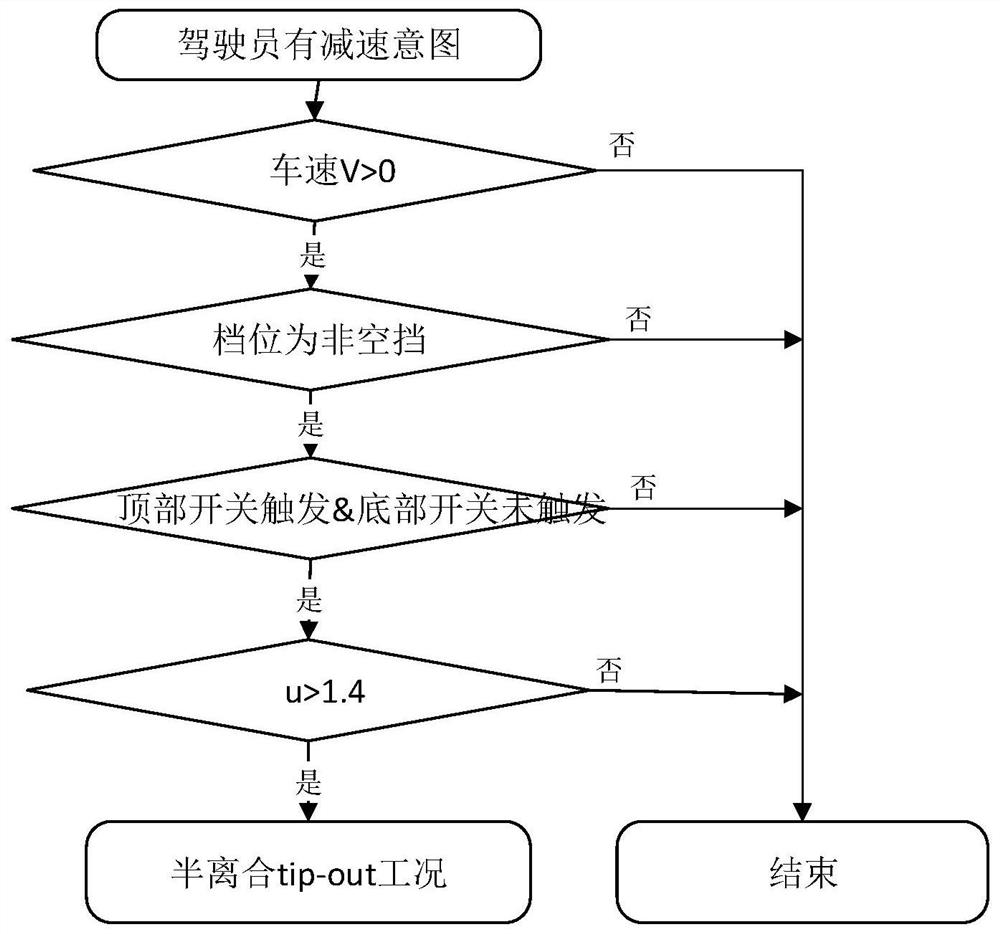

[0039] In this embodiment, first of all, it is necessary to confirm whether the vehicle has entered the semi-clutch tip-out working condition. The confirmation method is: estimate the speed of the output end of the clutch flywheel, that is, the speed of the gearbox input shaft ngearbox-input ,Calculated as follows:

[0040]

[0041] where: n gearbox-input - the speed of the gearbox input shaft;

[0042] no flywheel-out ——rotational speed of output end of clutch flywheel;

[0043] V—vehicle speed;

[0044] Ratio - the total transmission ratio of the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com