Arc grinding wheel dresser nib rotation radius measuring instrument and measuring method thereof

A technology of grinding wheel dresser and radius of rotation, which is applied in the direction of measuring devices, instruments, optical devices, etc., and can solve the problem that the radius data cannot be directly read out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

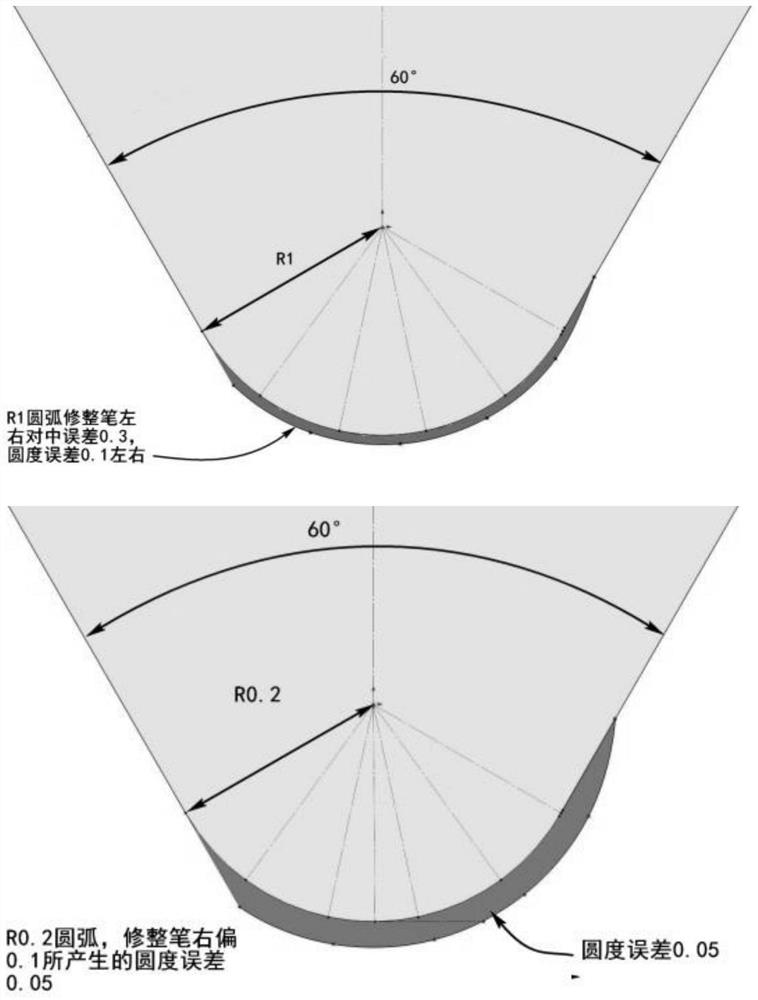

Problems solved by technology

Method used

Image

Examples

Embodiment 1

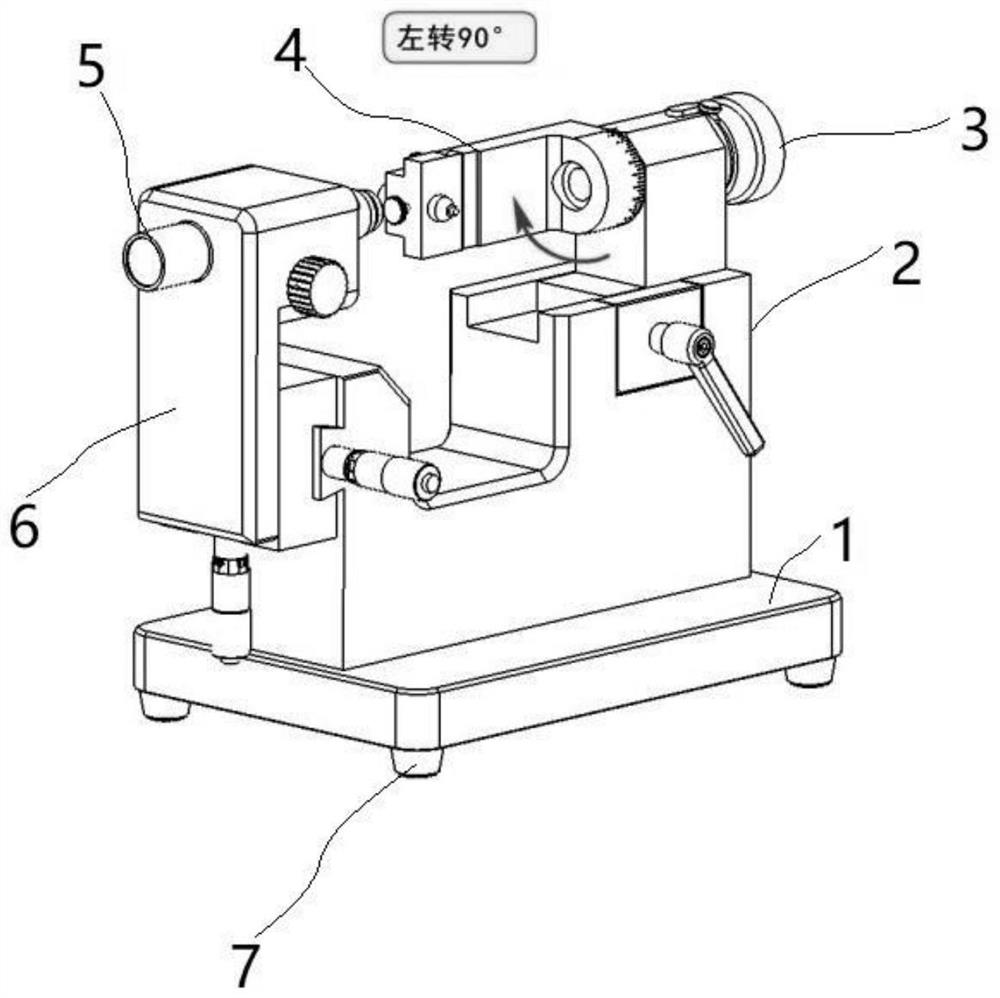

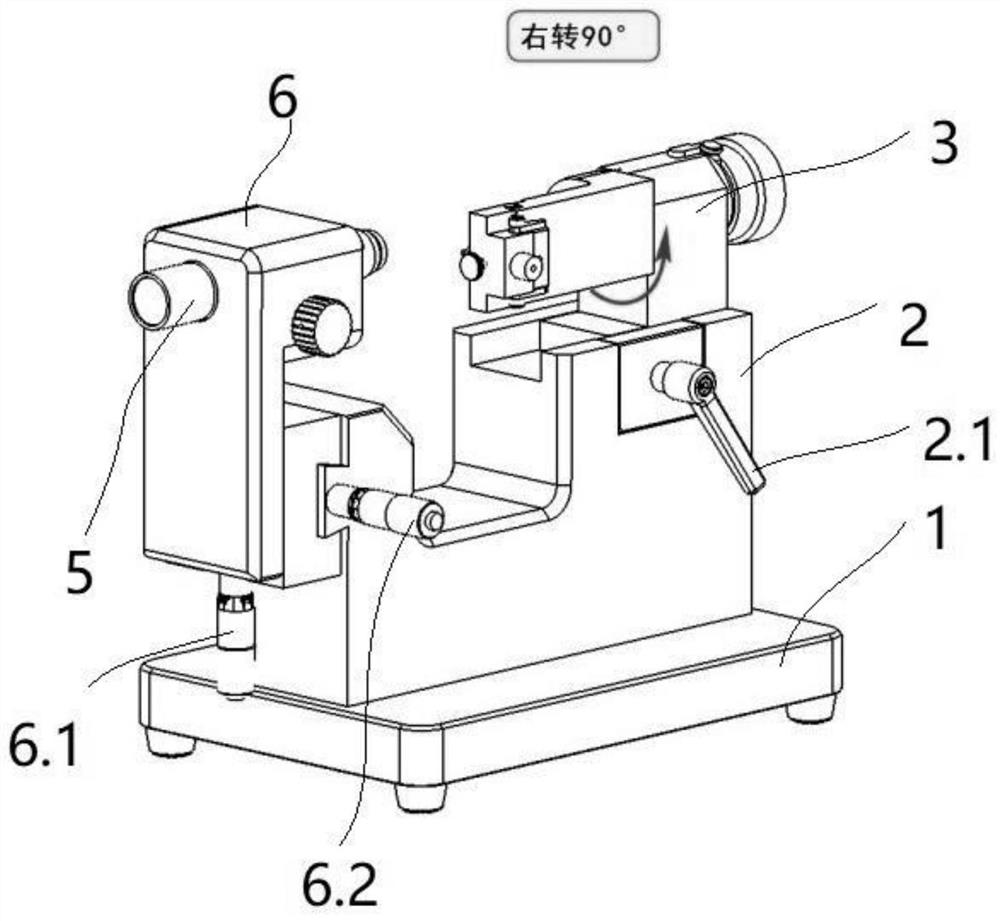

[0047] Such as Figure 2-4 Shown, a kind of circular arc grinding wheel dresser nib rotation radius measuring instrument, including

[0048] The base 1 is fixed with a "U"-shaped measuring platform 2, and one end of the "U"-shaped measuring platform 2 is provided with a Y up-down adjustment device 6.1 and an X left-right adjustment device 6.2.

[0049] The Y up and down adjustment device 6.1 and the X left and right adjustment device 6.2 are provided with a mirror holder 6, and the Y up and down adjustment device 6.1 and the X left and right adjustment device 6.2 are provided with a linear measuring device, which can clearly display the moving distance of the microscope 5 during use.

[0050] Microscope 5 is housed on the mirror base 6, and the central optical axis of the reticle of microscope 5 is C2-C2 ', as Figure 4 As shown, the microscope 5 is set horizontally, and the Y up and down adjustment device 6.1 and the X left and right adjustment device 6.2 control the up, dow...

Embodiment 2

[0055] Such as Figure 5 as shown,

[0056] A method for correcting left and right centering of a trimming nib, comprising

[0057] Make the central optical axis C2-C2' of the crosshair of the microscope always parallel to the rotation axis C1-C1' of the grinding wheel dresser;

[0058] Adjust the focus of the microscope so that the dressing tip of the grinding wheel dresser is clearly imaged on the microscope;

[0059] Rotate the trimming pen left and right by 90°, observe and adjust the highest point of the trimming pen tip in the microscope, so that the highest point of the trimming pen tip on the left and right sides is at the same height or on the same horizontal line; when adjusting, use the principle of 180°rotation of eccentricity error twice , so to adjust the highest point of the pen tip, it should be adjusted back half of the display distance, until the left and right rotation of the trimmed pen tip is 90°, the highest point of the pen tip is on the same horizonta...

Embodiment 3

[0061] A method for measuring the radius of rotation of a trimming nib, comprising

[0062] Place the grinding wheel dresser that needs to be adjusted in the installation step or chute, so that the central optical axis C2-C2' of the crosshair of the microscope is always parallel to the rotation axis C1-C1' of the grinding wheel dresser,

[0063] Adjust the focus of the microscope so that the dressing tip of the grinding wheel dresser is imaged on the microscope;

[0064] Rotate the trimming pen left and right by 90°, observe and adjust the highest point of the trimming pen tip in the microscope, so that the highest points of the trimming pen tip on the left and right sides are at the same height or on the same horizontal line;

[0065] Rotate the pen tip 90° to the left, adjust the cross measuring line of the microscope through the X left and right adjustment measuring device, make the vertical line of the cross measurement line coincide with the highest point of the pen tip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com