Movable slotted wire harness removal pliers for reduced frictional resistance

A friction resistance and moving groove technology, applied in the field of pliers, can solve the problems of damage to the wire harness joint 16 and the corresponding interface 17, damage to the wire harness joint and the corresponding interface, etc., and achieves the effect of wide application range, prolonging service life and reducing torsional moment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

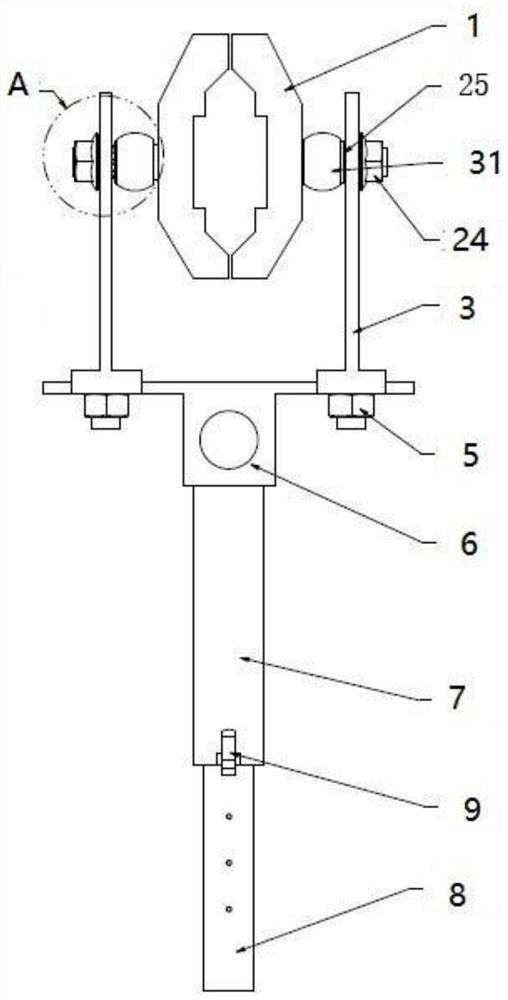

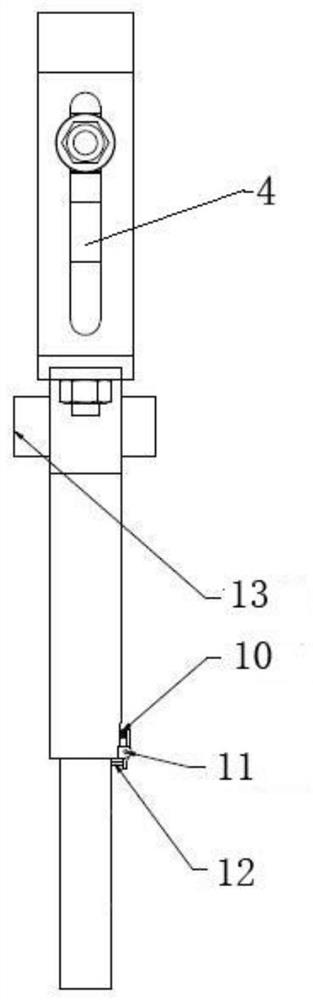

[0031] Example 1, see Figure 2-Figure 5 , a mobile trough wire harness removal pliers capable of reducing frictional resistance, including two symmetrically arranged pliers body units, a fixing seat 6 and a handle. The fixed seat is provided with a long hole 18; two pliers units are respectively placed on both sides of the fixed seat 6, and the pliers unit can slide along the long hole 18, so that the mobile trough-type wire harness removal pliers can adapt to wire harnesses of different diameters. The pliers body unit includes a pliers body 1, an installation shaft 2 and a moving bracket 3; the installation shaft 2 includes a third shaft segment 23, a second shaft segment 22, a first shaft segment 21 arranged in sequence, and the third shaft segment 23, the second shaft segment The radii of the shaft section 22 and the first shaft section 21 gradually increase to form a stepped shaft; the second shaft section 22 is provided with a ball bearing 25, and the ball bearing 25 abu...

Embodiment 2

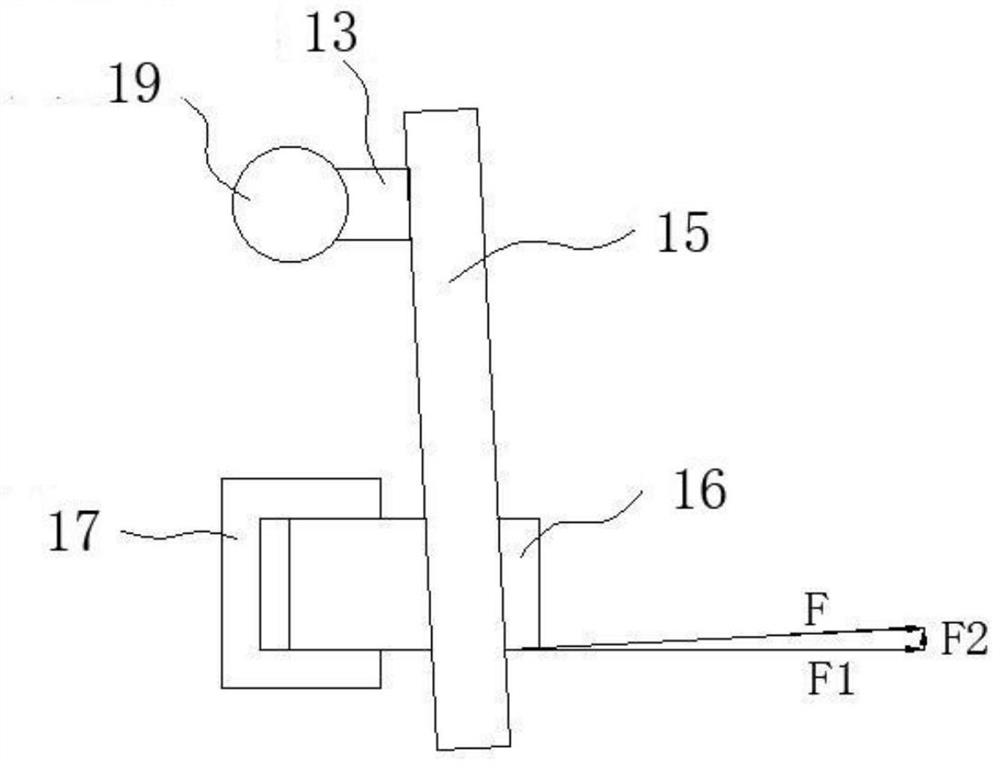

[0039] Example 2, see Figure 6-Figure 8 , the difference from Embodiment 1 is that the fixed seat 6 is rotationally connected with the rotating bracket 14 through the first rotating pin 20 , and the magnet 13 is arranged on the rotating bracket 14 . In this way, the magnet can also be adsorbed and fixed on the plane of the iron parts around the motor wiring harness of the new energy vehicle.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap