Compressor and air conditioner

A technology for compressors and compression chambers, which is applied in the field of compressors, and can solve problems such as sudden changes in the exhaust speed of compressors and sudden changes in the area of the exhaust port, so as to achieve the effects of improving energy efficiency, improving reliability and avoiding large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

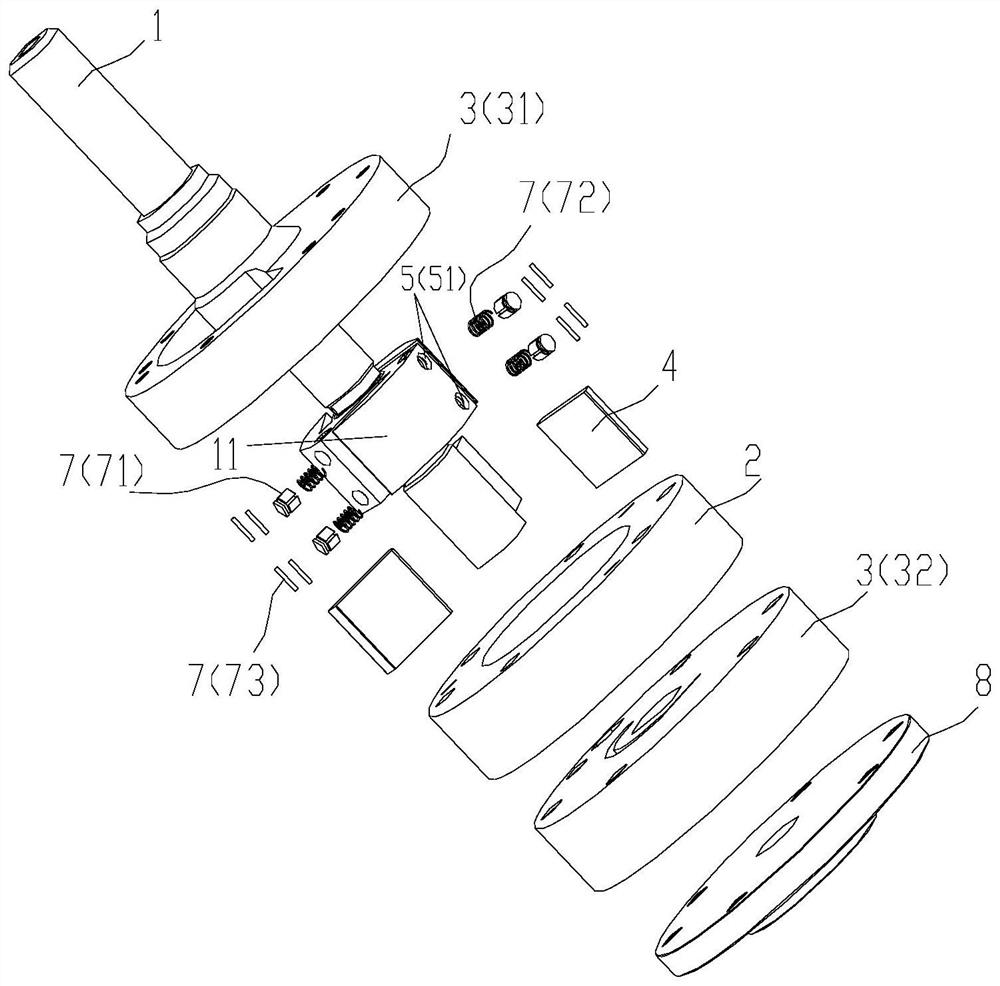

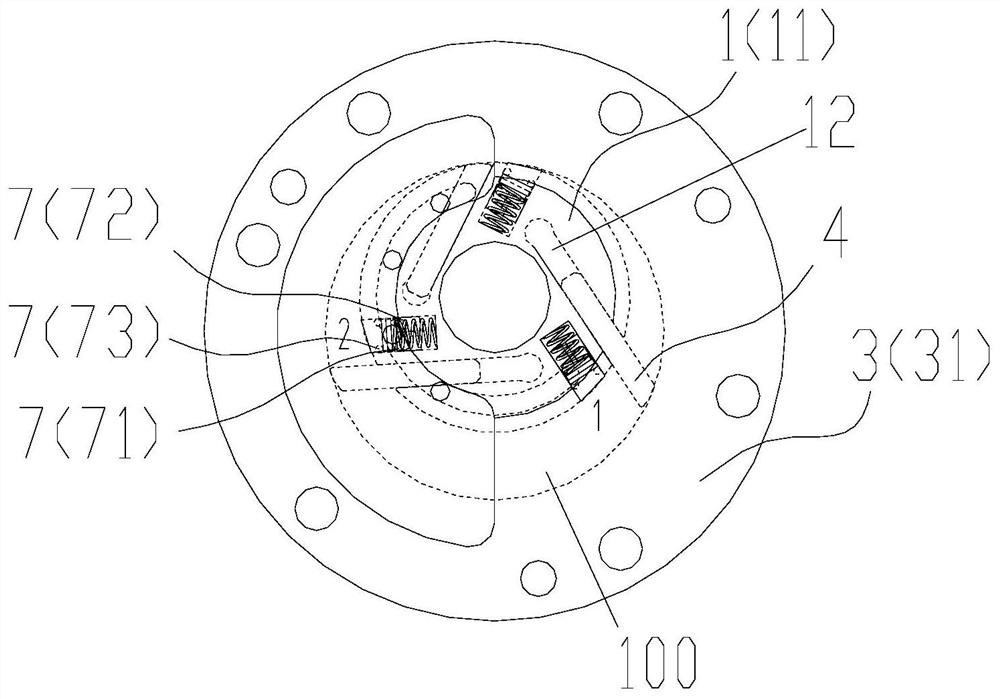

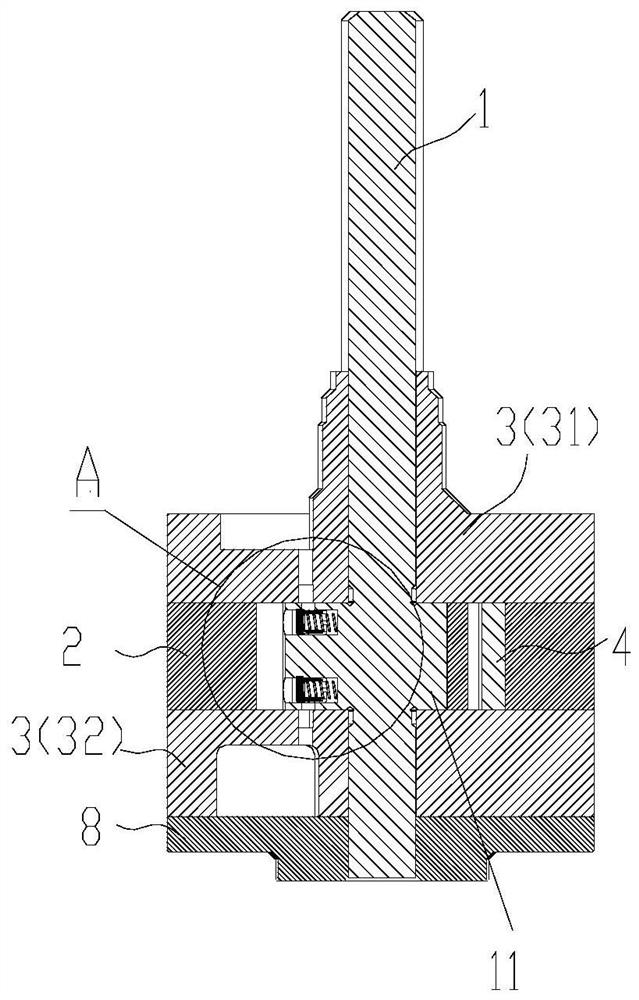

[0048] Such as Figure 1-10 As shown, the present invention provides a compressor, which includes:

[0049] The main shaft 1, the cylinder 2, the flange 3 and the sliding plate 4, the main shaft 1 includes a convex portion 11, the convex portion 11, the cylinder 2, the flange 3 and the sliding plate 4 jointly form a compression chamber 100 , the convex portion 11 is provided with at least one main shaft exhaust port 5 corresponding to each of the compression chambers 100, and the flange 3 is provided with a flange exhaust port 6, (preferably the flange row The air port is arranged opposite to the exhaust port of the main shaft in the radial direction, which can ensure that the flange exhaust port communicates with the exhaust port of the main shaft in the radial direction), and one end of each of the main shaft exhaust ports 5 is connected to the exhaust port of the main shaft. The compression chamber 100 communicates, and the other end can communicate with the flange exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com