Movable rotating mechanism for pump body spraying

A technology of rotating mechanism and pump body, applied in the direction of spraying device, etc., can solve the problems of low efficiency, trouble and poor effect, and achieve the effect of high efficiency, good effect and convenient automatic spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

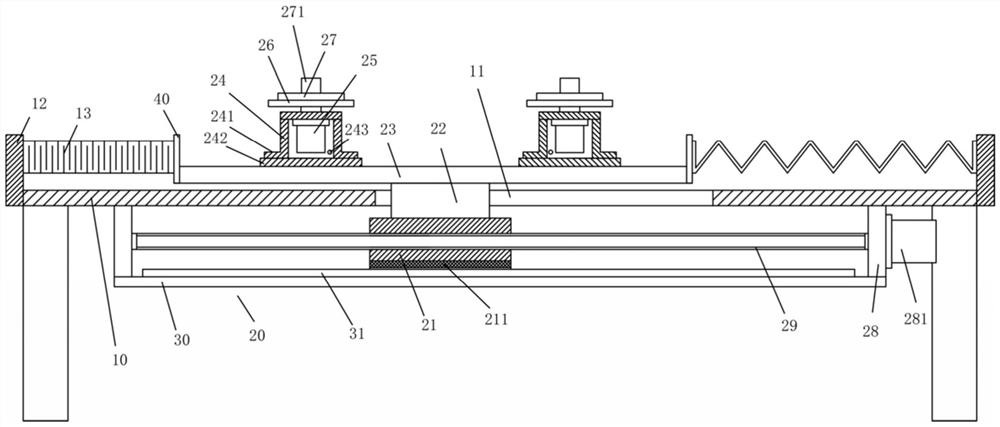

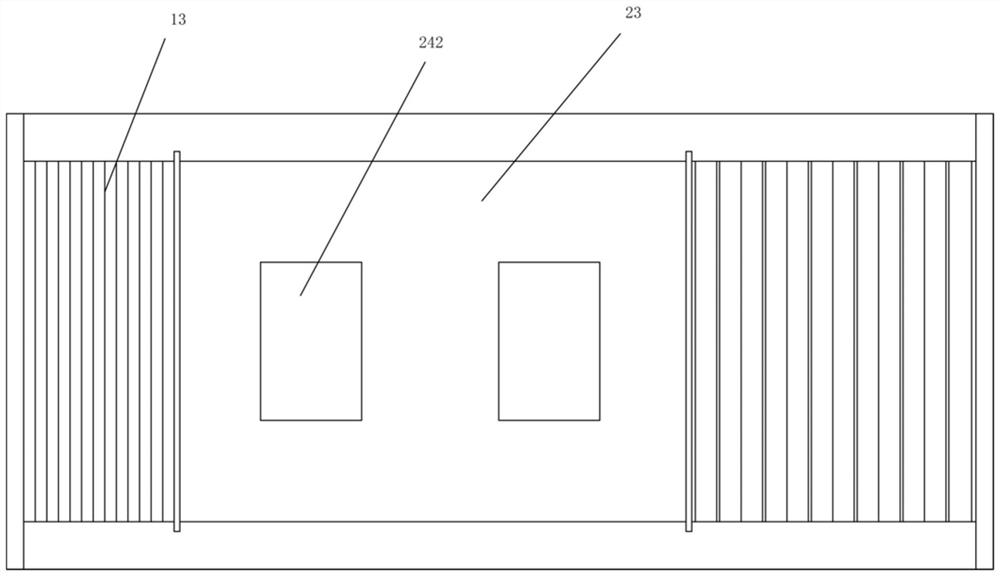

[0015] Examples, see e.g. Figure 1 to Figure 2 As shown, a moving and rotating mechanism for pump body spraying includes a frame 10, a central through groove 11 is formed in the middle of the top plate of the frame 10, and a lateral movement mechanism 20 is fixed on the bottom surface of the top plate of the frame 10 to move laterally. The top surface of the mobile block 21 of mechanism 20 is fixed with upper connecting block 22, and the top of upper connecting block 22 stretches out the top surface of the top plate of frame 10 and is fixed with transverse plate 23, and the left part of transverse plate 23 and the top of right part Both surfaces are fixed with a support base 24, the bottom surface of the top plate of the support base 24 is fixed with a rotating motor 25, the output shaft of the rotating motor 25 passes through the top surface of the top plate of the support base 24 and is fixed with a rotating fixed plate 26, and the rotating fixed plate 26 A connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com