An anti-biting photovoltaic cable

A photovoltaic cable and cable technology, which is applied to insulated cables, bendable cables, cables, etc., can solve the problems of photovoltaic cables that cannot be bitten and inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

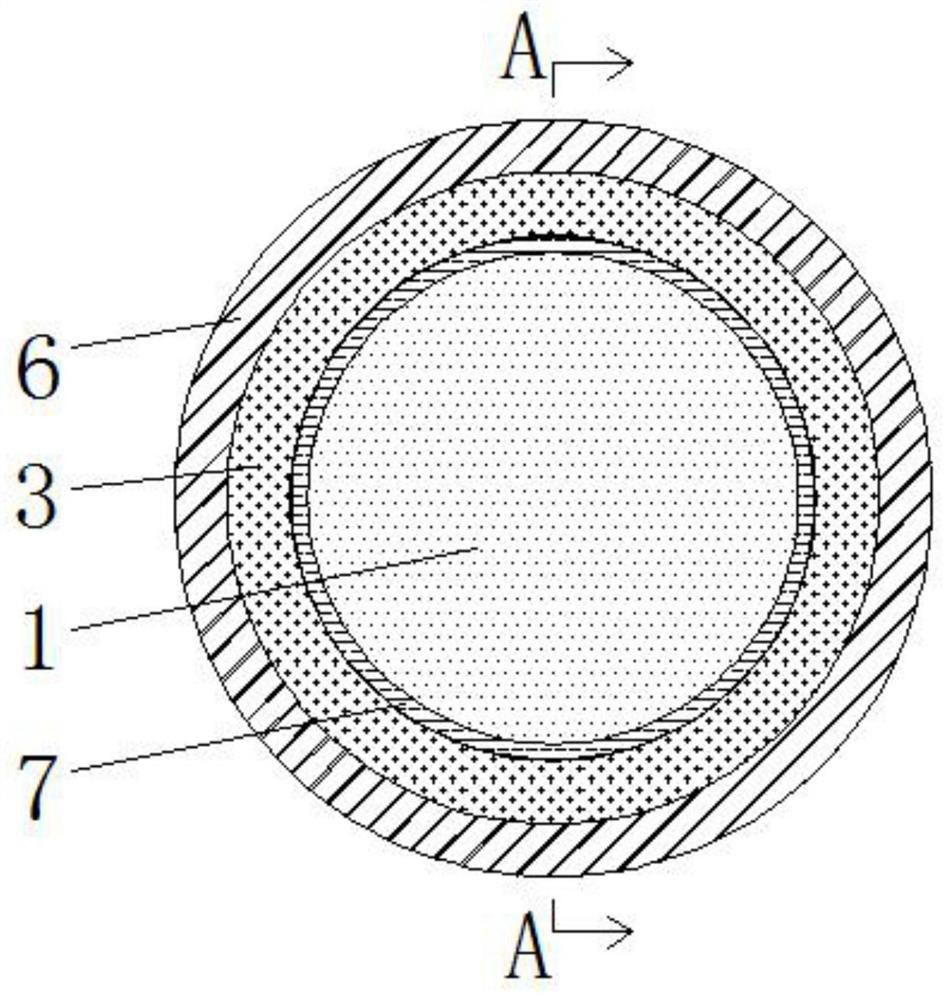

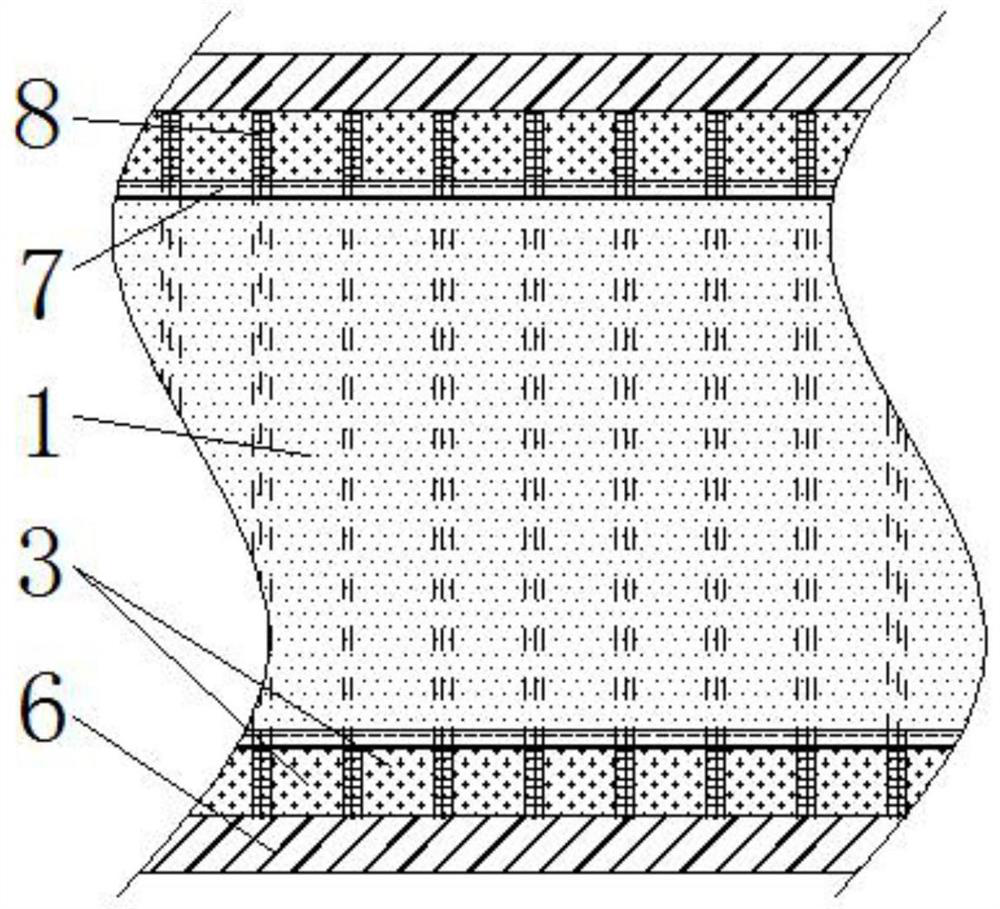

[0032] like figure 1 and figure 2 An anti-gnawing photovoltaic cable shown includes a cable main body 1 arranged at the center of the cable and an outer sheath 6 that is covered and located on the surface of the cable; The rotating ring body 10 includes a plurality of annular sheathing layers 3 that are sheathed one by one along the length of the cable body 1 , and each adjacent two annular sheathing layers 3 are attached to each other.

[0033] In this embodiment, as figure 2 As shown, elastic adhesive layers 8 are fixed on both end surfaces of each annular sleeve layer 3 . Based on the fact that each ring-shaped jacket layer 3 can rotate independently, the elastic glue layer 8 can be compressed, which can promote the bendability of the rotating ring body 10, so that the bendability of the cable is not affected, and the arrangement of the cable is facilitated.

[0034] In this embodiment, as figure 1 and figure 2 As shown, the outer side of the cable body 1 is covered...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is:

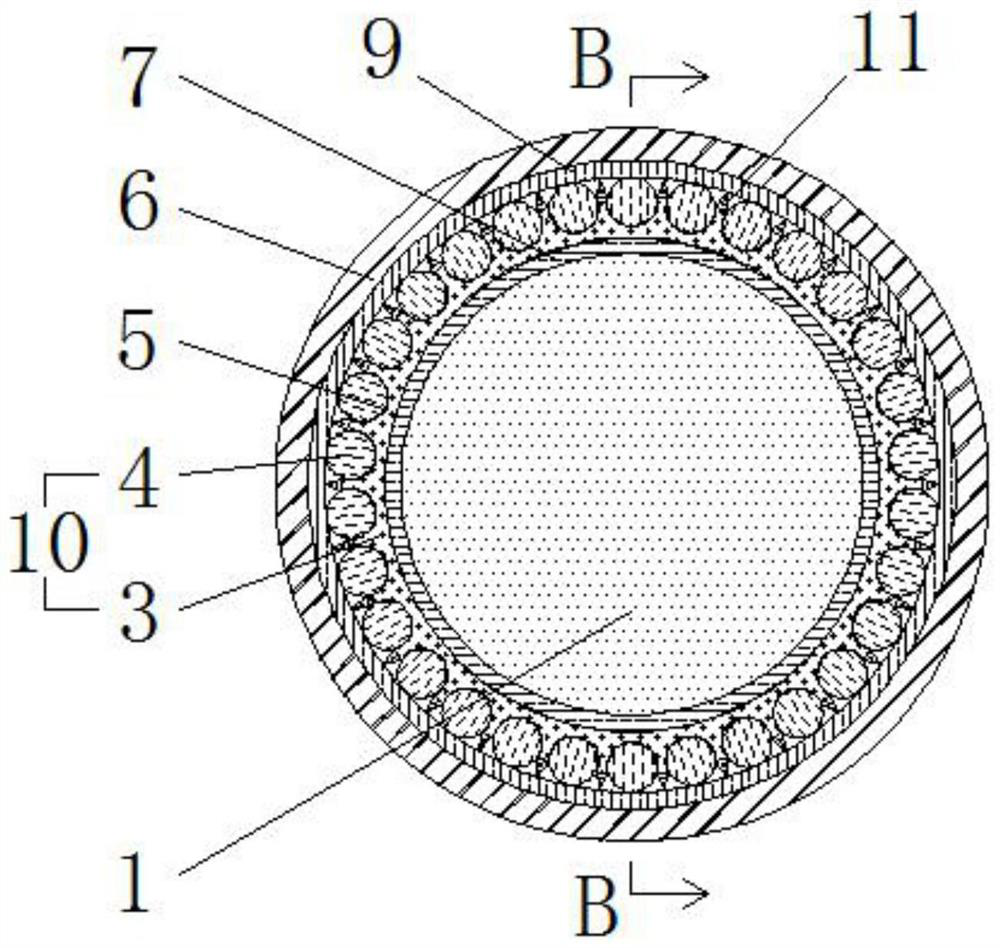

[0040] In this embodiment, as image 3 and Figure 4 As shown, the rotating ring body 10 also includes a plurality of balls 4 embedded in the outer surface of the annular sleeve layer 3. The annular sleeve layer 3 is evenly provided with universal grooves 5 for embedding the balls 4. A rotatable ball 4 is embedded in the groove 5 , and less than half of the ball 4 is located outside the universal groove 5 . When the ball 4 is bitten, it can rotate in the universal groove 5 and is not easy to be bitten successfully, so that the anti-bite function of the cable can be enhanced.

[0041] Further, the materials of the balls 4 and the annular sleeve layer 3 are both flame-retardant plastics. The flame-retardant plastic is light in weight, suitable for use in cables, and has flame-retardant properties, which can enhance the flame-retardant function of cables.

[0042] Further, as image 3 and Figure 4 As show...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 2 is:

[0049] In this embodiment, as Figure 5 As shown, the outer side of the cable body 1 is provided with an inner sheath 2, and the materials of the inner sheath 2 and the outer sheath 6 are both added with materials with a pungent odor. The inner sheath 2 can enhance the protection function of the main body of the cable, and adding materials with irritating odors can drive away animals such as snakes, insects, rats, ants, etc., such as mint, aromatherapy, mothballs, etc. odor, which can enhance the anti-rat bite performance of the cable.

[0050] Further, as Figure 5 and Image 6 As shown, the outer sheath 6 includes an inner sheath layer 61 and an outer sheath layer 62 covering the outer side of the inner sheath layer 61. One side of the inner sheath layer 61 is cut to form a crack, and the outer sheath layer 62 corresponds to the inner sheath layer 61. The side opposite to the side where the crack is loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com