Press spring type terminal block structure

A terminal block, conductive terminal technology, applied in the direction of clamping/spring connection, electrical components, connection, etc., can solve problems such as inconvenience, and achieve the effect of convenient plugging operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and drawings related to the present invention, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

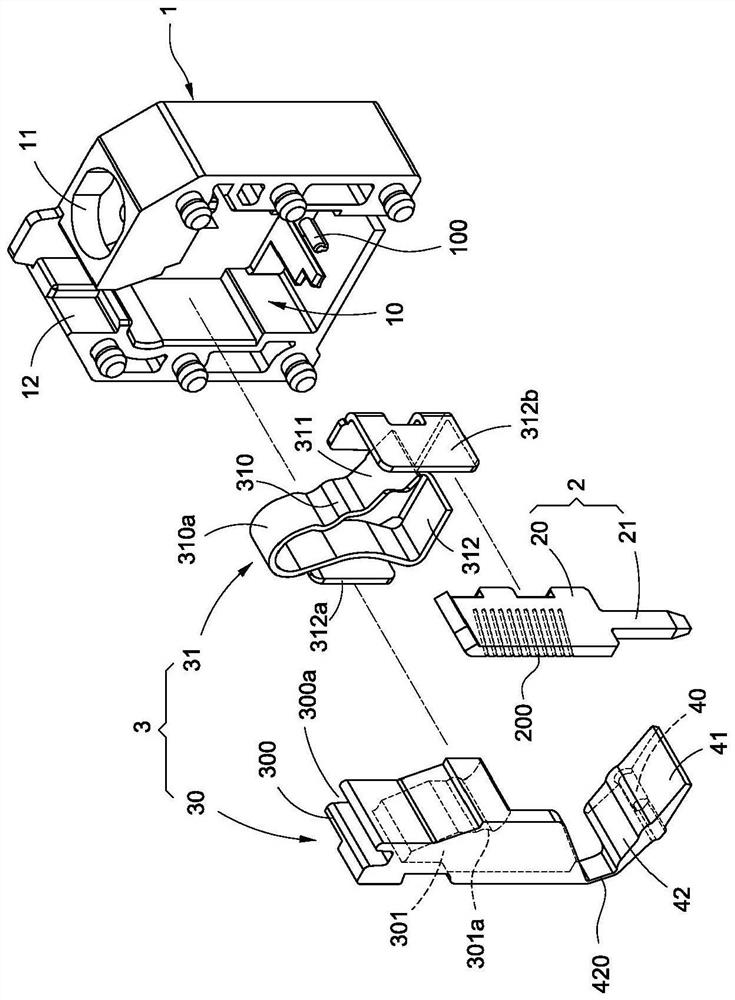

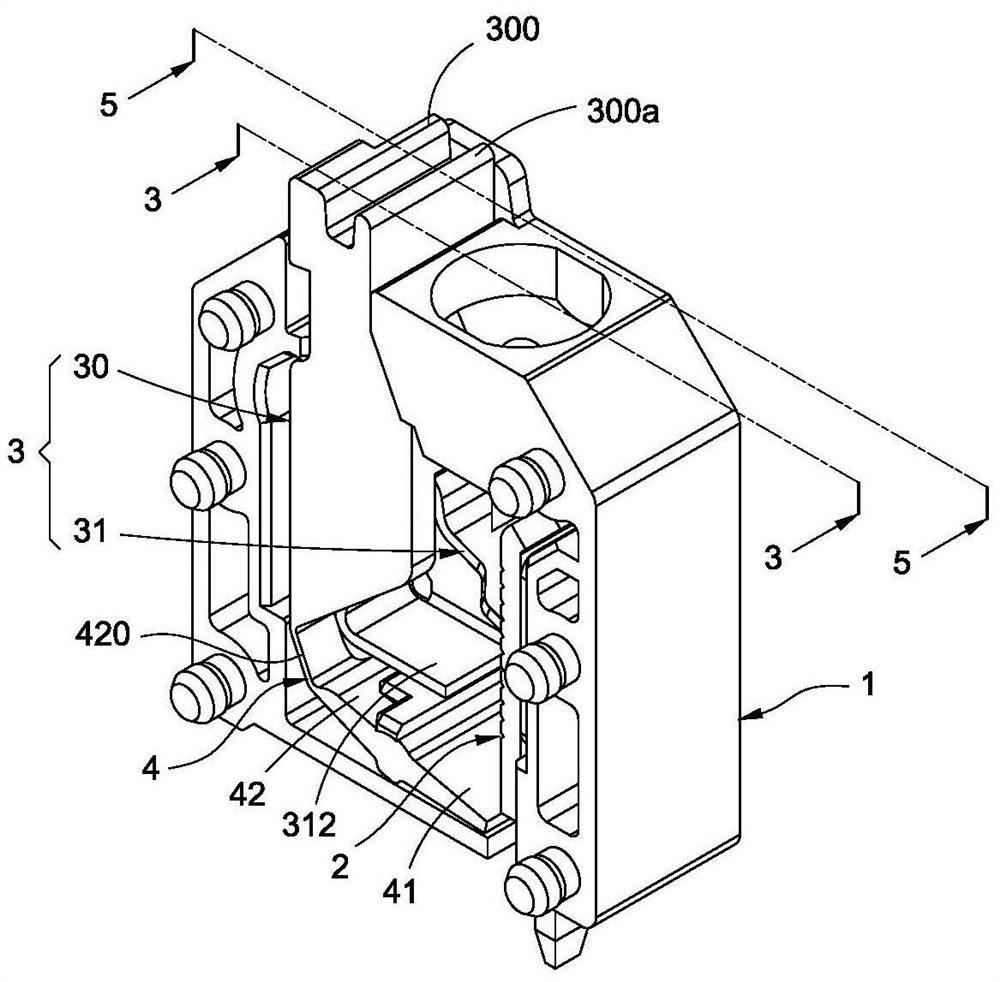

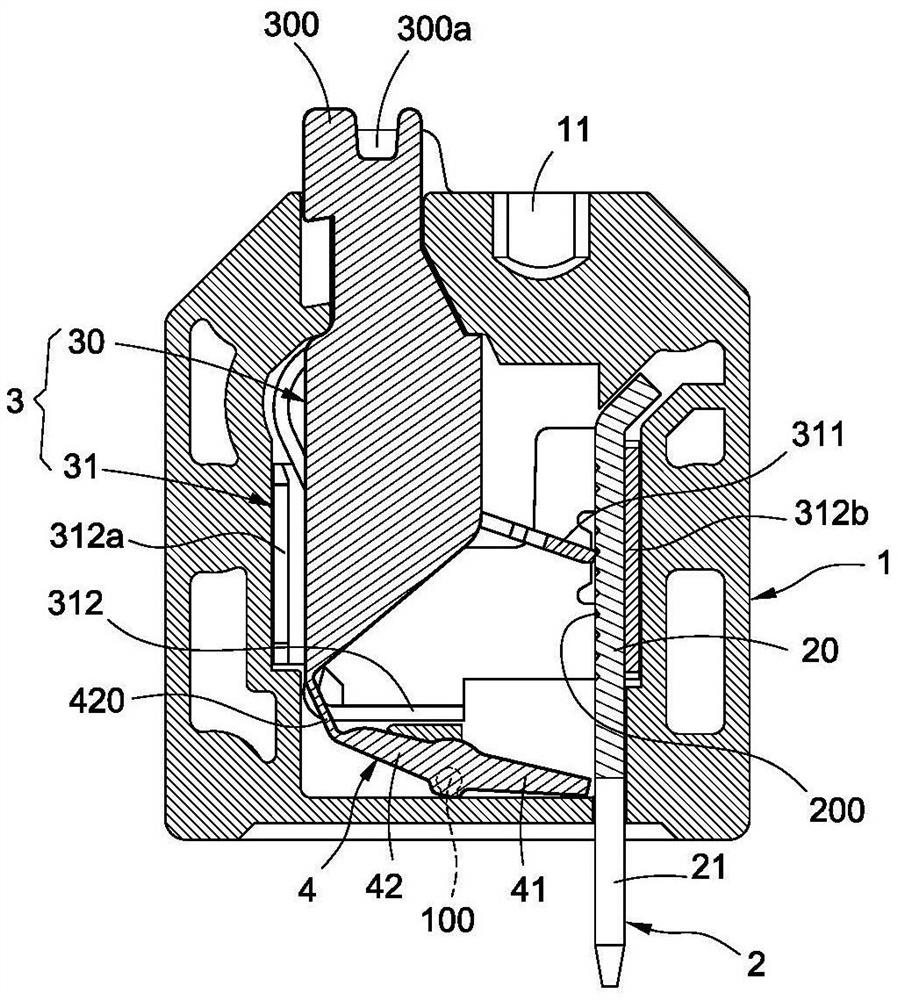

[0019] see figure 1 and figure 2 Shown are the three-dimensional exploded view and the three-dimensional assembled view of the first embodiment of the present invention, respectively. The present invention provides a push-rebound type terminal block structure, which is convenient for a wire 5 to be inserted in order to complete the electrical connection between the terminal block and the wire. The terminal block includes a frame body 1, a conductive terminal 2, a pressing component 3 and a seesaw structure 4; wherein: the frame body 1 can be made of insulating material, and can be added depending on the number of wires 5 to be inserted arrangement. And in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com