Pipe gallery inspection robot with adjustable axle distance

An inspection robot and adjustable technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inconvenient communication, many structures, and high labor intensity of workers, so as to reduce or avoid maintenance interruption and strengthen the early warning mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

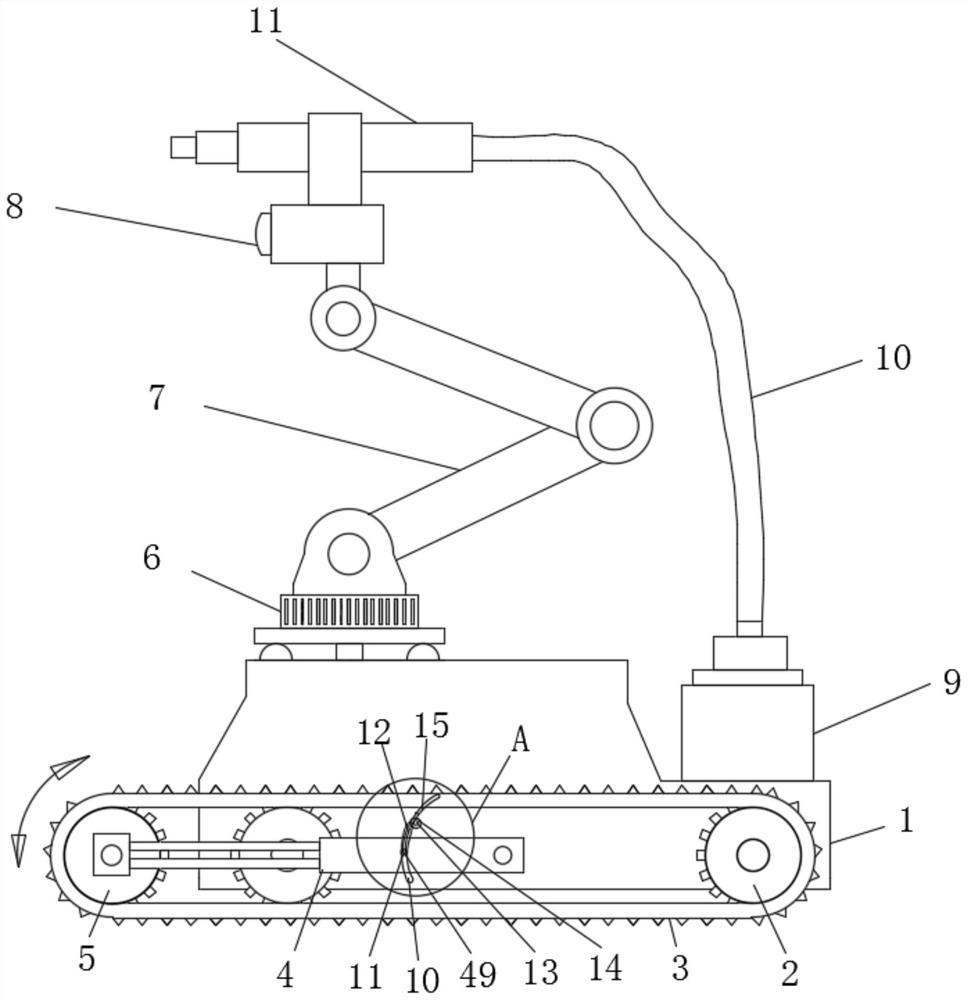

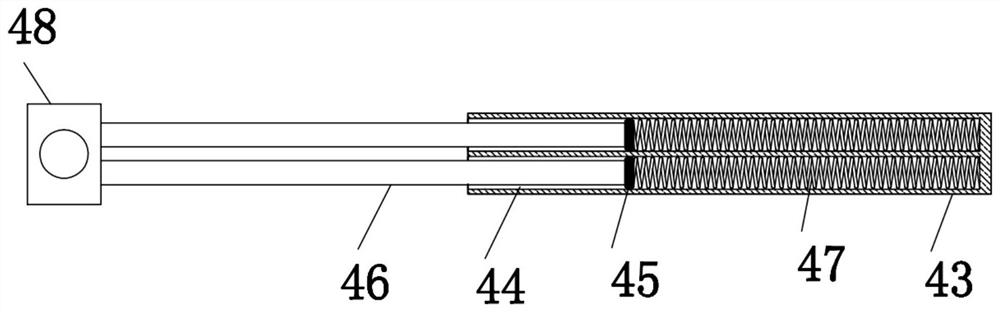

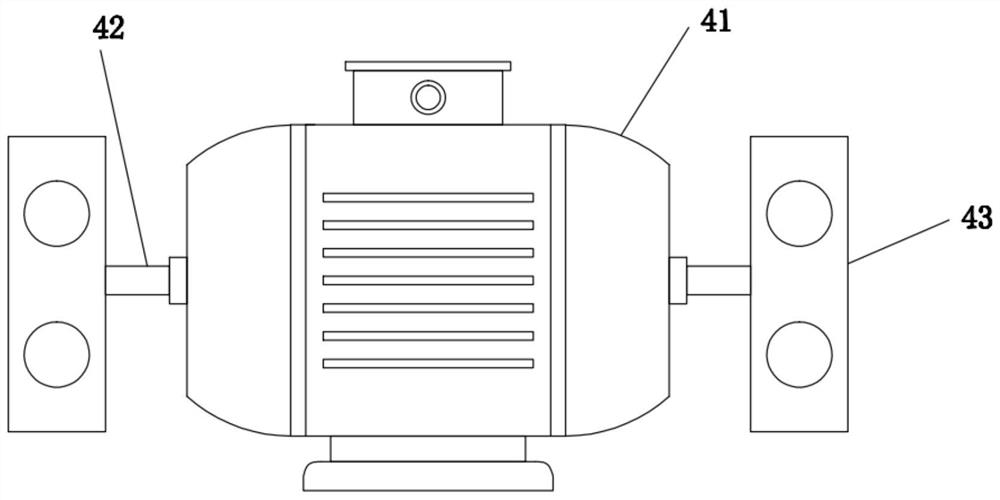

[0031] Please refer to Figure 1-Figure 5 , the pipe gallery inspection robot with adjustable wheelbase includes: a walking base 1, four track wheels 2 are installed on the walking base 1, wherein, every two track wheels 2 are a track wheel set, and the track wheels A crawler belt 3 is set on the wheel set, and a wheelbase adjustment device 4 is installed on the walking base 1, and the wheelbase adjustment device 4 is adapted to the crawler belt 3;

[0032] Rotating platform device 6, described rotating platform device 6 is installed on the top side of described walking base 1;

[0033] Mechanical arm assembly 7, described mechanical arm assembly 7 is installed on the top side of described rotary platform device 6;

[0034] Installation platform 8, described installation platform 8 is rotatably installed on the top of described mechanical arm assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com