Error prevention method applied to tobacco primary processing and charging control system

A material feeding control system and error prevention technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve problems such as normal display value, excessive material liquid addition, and inaccurate flow meter measurement, so as to ensure accuracy, strengthen early warning mechanism, The effect of avoiding particle contamination of feed liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

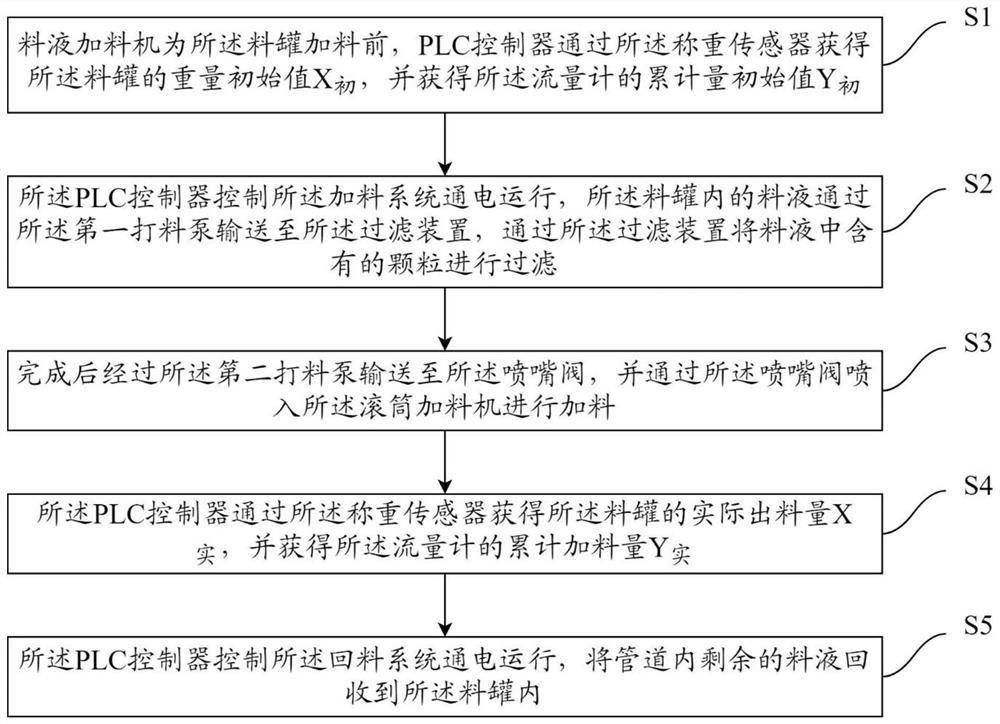

[0044] Refer to the attachment figure 1 As shown, the present invention provides a technical solution: an anti-differential method for applying the tobacco silk filament control system, including the following steps:

[0045] S1, the liquid feeder is used as the tank 1, the PLC controller obtains the weight initial value of the tank 1 through the weighing sensor 2. 初 And obtain the integrated amount of the initial value of the flowmeter 7 y 初 .

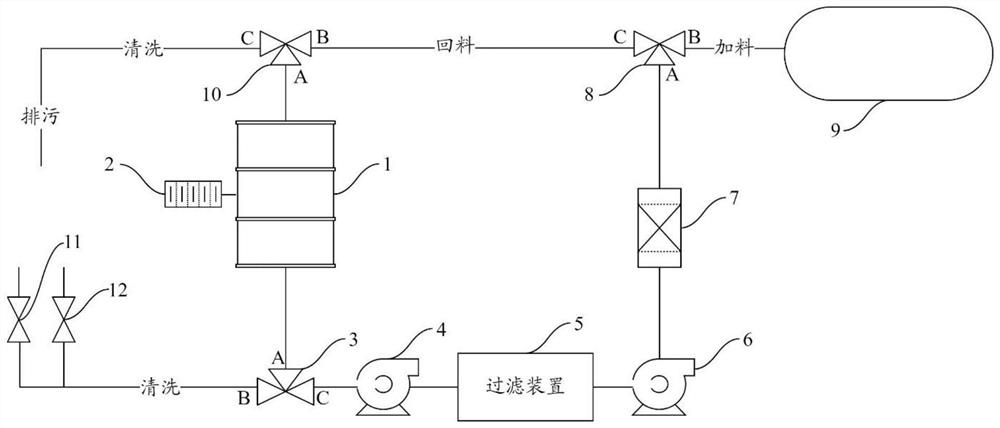

[0046] S2, the PLC controller control the feeding system is powered, and the material in the tank 1 is delivered to the filter device 5 by the first printing pump 4, and the particles contained in the material are filtered through the filter device 5.

[0047] Specifically, the feeding system introduces the filter device 5, during which the particles containing the filtration device 5 are filtered, and the particles are accumulated in the pipe. Further, after filtration of the particles, the accuracy of the particles affect the flowmeter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com