Tobacco perfuming control method and tobacco perfuming control device

A technology of tobacco flavoring and control methods, which is applied to tobacco, injection devices, and tobacco preparation, and can solve problems such as uneven flavoring of tobacco, affecting cigarette smoking quality, and spot smoke, and achieve the effect of avoiding production quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In Example 1, the present invention was applied to a tobacco leaf moisturizing feeder.

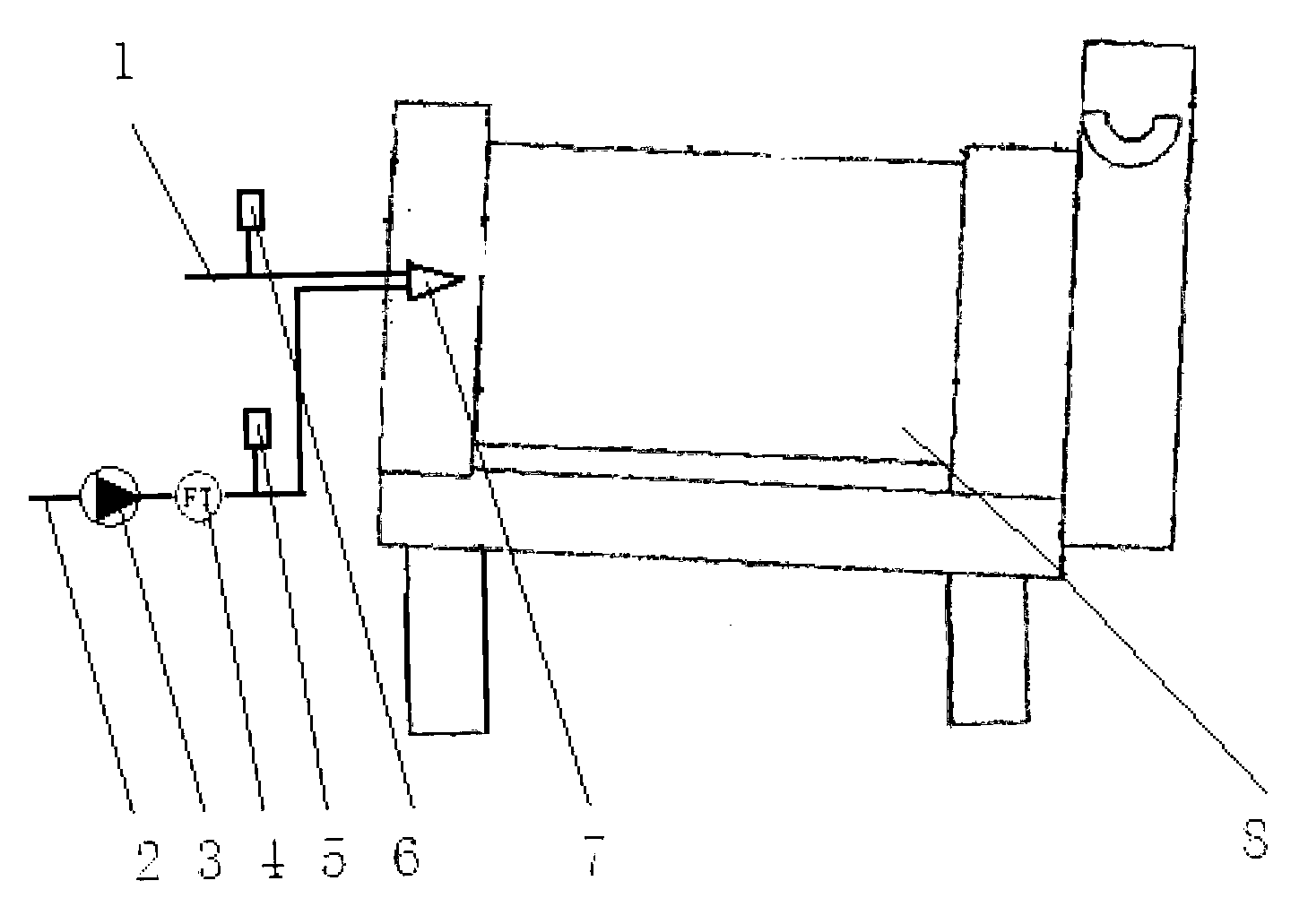

[0020] See figure 1 The specific steps to realize the control method are: first set the upper and lower limits of the material liquid pressure detected by the material liquid pressure sensor 5 in the control system as P1 (0.3MPa) and P2 (0.2MPa); set the medium detected by the medium pressure sensor 6 The upper and lower pressure limits are respectively P3 (0.25MPa) and P4 (0.15MPa); and the pressure difference between the material liquid pressure sensor 5 and the medium pressure sensor 6 is P5 (0.15MPa). If the material liquid pressure exceeds the range of P1 to P2, or the medium pressure exceeds the range of P3 to P4, or the pressure difference between the material liquid pressure and the medium pressure exceeds P5, the control system will issue an alarm.

[0021] After the application of the present invention, an alarm can be issued according to the setting of the control system. Onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com