Automatic ash unloading control system of circular cooling ash unloading trolley

A control system and automatic unloading technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of inability to unload ash from the ring-cooled ash unloading trolley, poor stability of furnace charge quality, and high labor intensity of workers. Achieve the effects of reducing labor intensity, improving operation stability and safety, and avoiding production quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

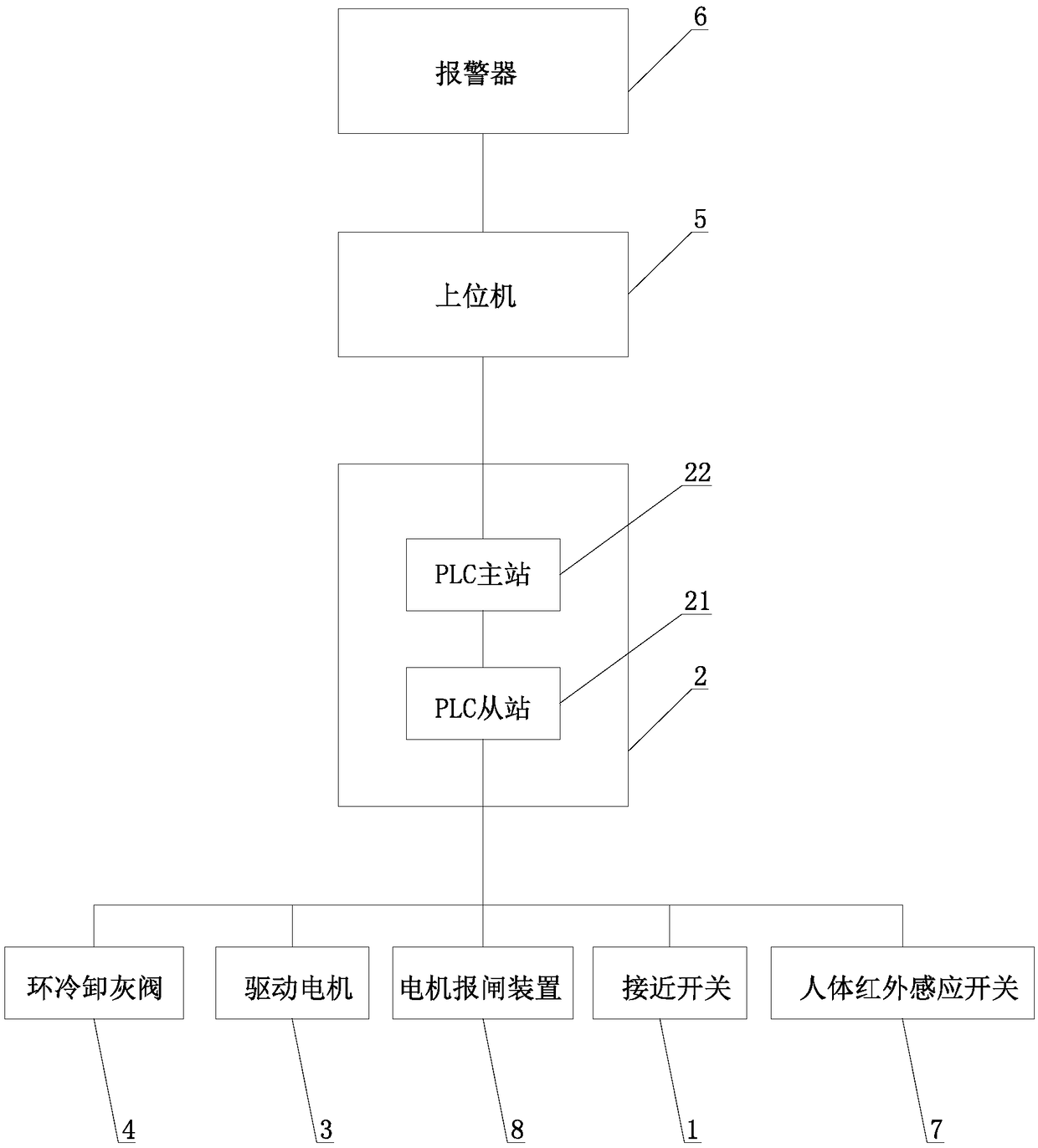

[0012] Such as figure 1 As shown, in the automatic ash unloading control system of the ring-cooled ash unloading trolley, a proximity switch 1 is installed on each ash unloading point of the trolley track, and a proximity switch 1 is installed on the ring-cooled ash unloading trolley to cooperate with the proximity switch 1. All proximity switches 1 are connected to PLC controller 2 at the same time, and PLC controller 2 is also connected to the drive motor 3 of the ring-cooled ash unloading trolley, the ring-cooled ash unloading valve 4 of the ring-cooled ash unloading trolley, and the upper position The computer 5 is connected to the signal, and the host computer 5 is connected to the alarm 6; the PLC controller 2 can control the driving motor 3 and the ring cooling ash discharge valve 4 according to the car arrival signal sent when the proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com