Batching belt weigher shaft breakage detection and alarm system

A technology of batching belt scale and alarm system, which is applied in transportation and packaging, conveyor objects, conveyor control devices, etc., can solve problems such as production quality accidents, unqualified charge components of finished products, and batching deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

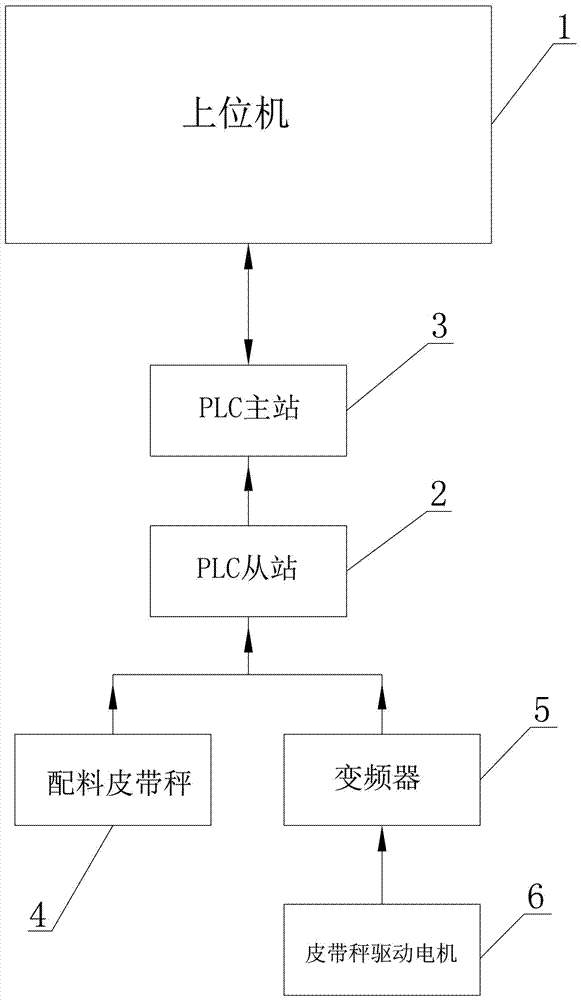

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the broken shaft detection and alarm system of a batching belt scale includes a host computer 1, a PLC slave station 2 and a PLC master station 3, and the host computer 1 is used to set the broken shaft judgment parameter of the batching belt scale 4 , and send the broken axis judgment parameter to the PLC master station 3, wherein the broken shaft judgment parameter includes the broken shaft judgment value, the value time frequency and the broken shaft judgment time. In the present embodiment, the broken shaft judgment parameter broken shaft judgment value is 0.1 t / h, the value time frequency is 5s, and the broken shaft judgment time is 30s; the PLC slave station 2 can collect the operation signal and the instantaneous flow rate of the batching belt scale 4 in real time, and will collect the batching belt scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com